Posted on 01/03/2025 7:11:06 AM PST by Red Badger

Researchers have discovered a chemical-free method for recovering 99.9% of the gold from recycled electronic waste, or e-waste, then using the recovered gold to transform harmful carbon dioxide into useful organic materials.

Led by post-doctorate researcher Amin Zadehnazar, who works in the lab of Alireza Abbaspourrad, a professor of food chemistry and ingredient technology, the process offers a non-toxic method for recovering precious metals from waste material and cleaning the environment.

Organic Matrix Recovers 99.9% of the Gold from Electronic Waste

Specifically, Zadehnazar synthesized a set of organic materials known as covalent organic frameworks linked with vinyl, known for their ability to extract gold ions and nanoparticles found in electronic devices while ignoring plastic and other metals like nickel and copper. When the Cornell researcher applied his synthesized COFs to selected electronic waste materials, including circuit boards with higher amounts of gold than other discarded materials, he found the mix captured 99.9% of the gold and very little of the nickel and copper within the same e-waste.

According to Zadehnazar, whose work took place in the National Science Foundation-funded Cornell Center for Materials Research and the Cornell NMR facility, the COF’s ability to extract and trap gold ions in the matrix not only offers a method for recovering the valuable material but also creates a perfect catalyst for converting carbon dioxide into organic chemicals used in several industrial and commercial applications.

“We can then use the gold-loaded COFs to convert CO2 into useful chemicals,” the researcher explained in a statement. “By transforming CO2 into value-added materials, we not only reduce waste disposal demands, we also provide both environmental and practical benefits.”

“It’s kind of a win-win for the environment,” he added.

E-Waste Programs Have Faced Challenges Staying Green

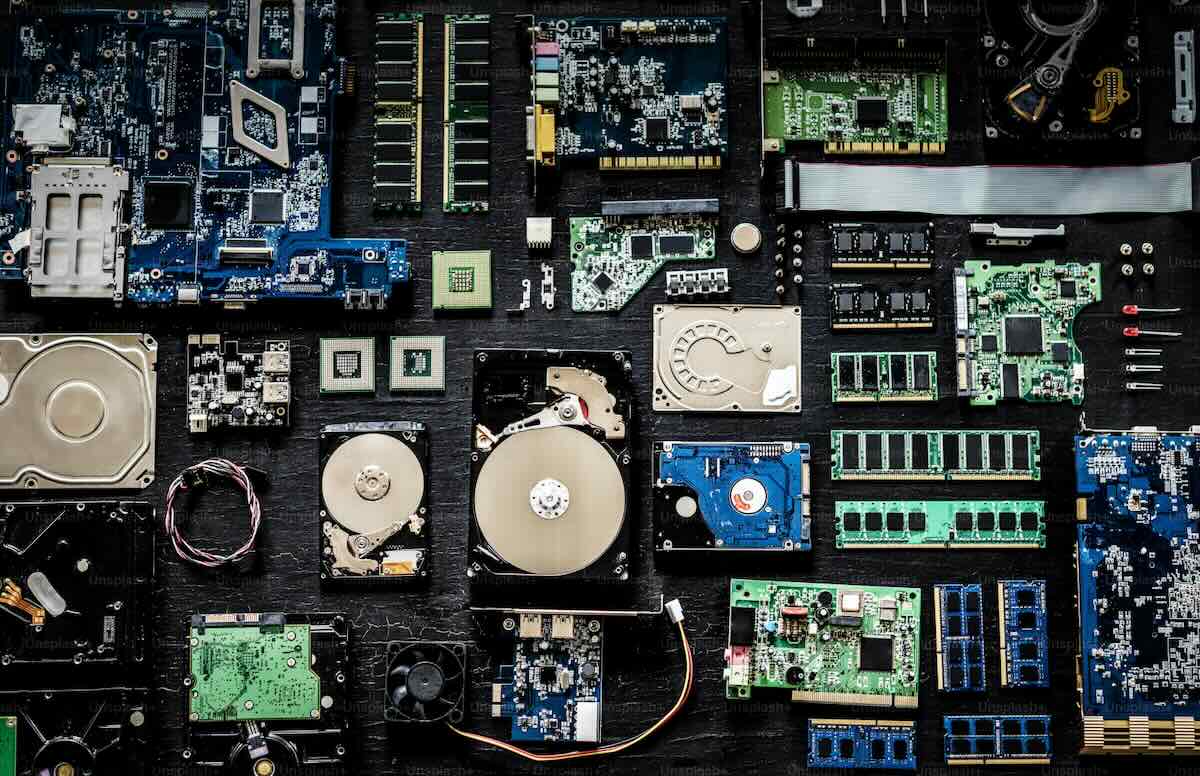

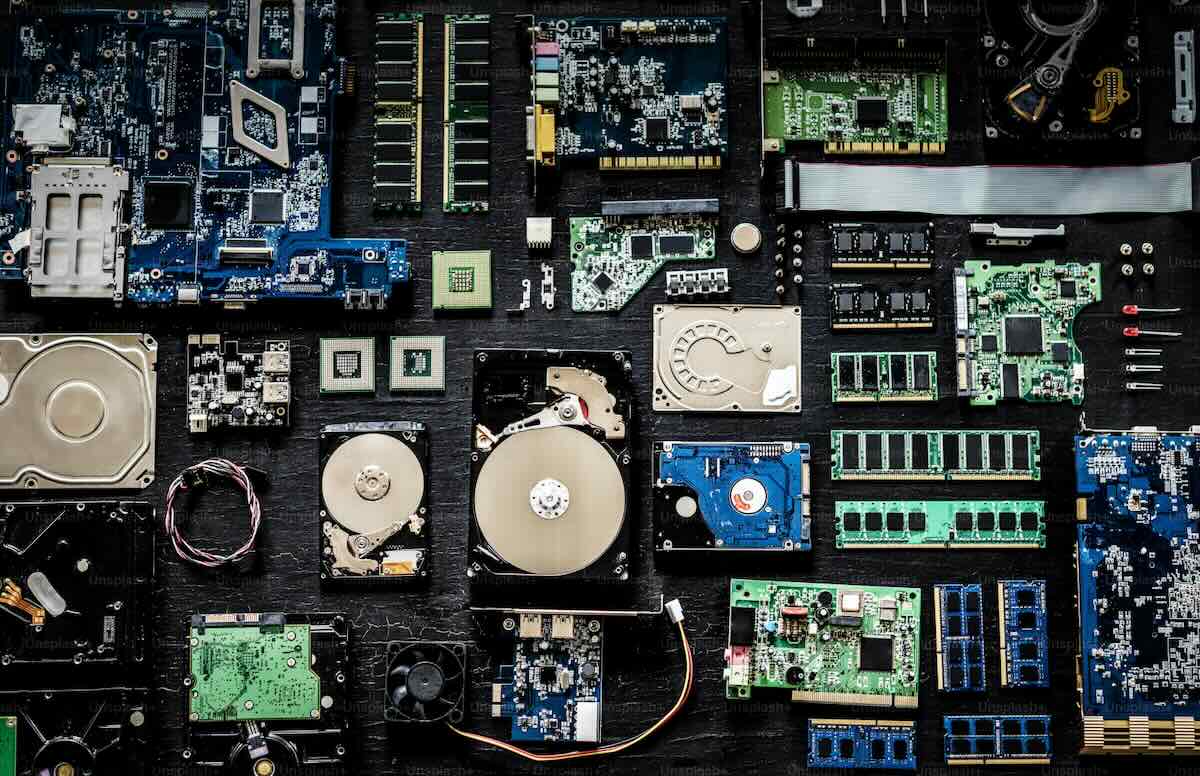

Although several states in the U.S. have electronic waste recycling programs aimed at reducing their disposal in landfills while also recapturing the valuable materials found in the guts of old computers, wires, cell phones, and other electronic devices, most have found it difficult to extract that material in a safe and non-toxic way.

California’s e-waste program began over two decades ago and was initially successful at recovering highly toxic CRT TVs that preceded the flat-screen LEDs sold today. However, that program has faced critical cost overruns as out-of-state televisions are regularly recycled in California. A similar problem plagues the aluminum can recycling program in California, which routinely pays out more money than it takes in due to out-of-state cans recycled locally.

These programs’ efforts to recover precious metals from electronic waste have also faced environmental concerns due to the chemicals used. The process can also be very energy intensive, making a program designed to reduce the carbon footprint a net polluter.

Still, proponents of these programs argue that they are still much more cost-efficient than traditional gold ore mining. According to the Cornell research team, “It’s estimated that a ton of e-waste contains at least 10 times more gold than a ton of the ore from which gold is extracted.” They also argue that given the anticipated 80 million metric tons of e-waste by 2030, “it’s increasingly important to find ways to recover that precious metal.”

Based on his successful tests, Zadehnazar believes his COF-based process offers the first viable solution that works without these chemicals. It also provides a CO2 conversion, making it a key component of a truly environmentally friendly green electronic waste recycling program.

The study “Recycling e-waste into gold-loaded covalent organic framework catalysts for terminal alkyne carboxylation” was published in Nature Communications.

Christopher Plain is a Science Fiction and Fantasy novelist and Head Science Writer at The Debrief. Follow and connect with him on X, learn about his books at plainfiction.com, or email him directly at christopher@thedebrief.org.

Golden Ping!..........................

People who currently retrieve the gold from circuit boards are not interested in that gold doing anything with co2, they want the gold itself.

Less deadly than C uhoh 2.

“chemical-free method”

“synthesized a set of organic materials known as covalent organic frameworks linked with vinyl”

The article quickly contradicts itself.

Beautifully written and ready for inclusion into 1) grant applications from the federal government and 2) the prospectus for luring venture capital to invest in Zadehnazar's BIL's newly formed LLC.

LOL…California do-gooders hoist on their own do-gooder petard. Figures.

I don’t see anything about the cost of this method.

If it cannot produce more value than it costs, it is useless.

There’s already a widespread simple way to turn carbon dioxide into safe organic material, plants.🌱 🌲🌳

Thanks Red Badger.

The Youtube channel "sreetips" has many videos detailing how to extract and refine gold and silver. It takes some special safety equipment to deal with the chemical fumes.

It's probably heavily dependent upon scaling. Doesn't sound like it's there yet. But at the current price of gold, I'd bet he'll have takers.

The back yard smelters that the Chinese use to “refine” gold are far worse than anything I have ever seen. If this causes them to only produce half as much pollution as they currently do, it is a win-win for everyone.

https://youtu.be/-mj4Wd_rmvM?si=_n3tO_eJCGqvVjFS

This is the key take away.

““It’s estimated that a ton of e-waste contains at least 10 times more gold than a ton of the ore from which gold is extracted.”l

Having worked in Guyana on a gold mine I can assure you getting gold from Ewaste is more environmentally friendly than hydraulic mining. You first strip mine off all the jungle above the deposits, then using high pressure water hoses you turn to liquid all the underlying strata with the runoff going into sluces where the dense material is separated from the lighter clays and muds. You then use acids to leech the microscopic gold particles out of the remaining materials. All the runoff goes directly into the local watershed untreated I might add. Gold is $2600+ TOZ today if they got 99.9% out of ewaste they are making money for sure as its gold content is an order of magnitude higher than ore you can use chemicals in the $100+ per litre range and laugh all the way to the bank. MOF are cheap they are industrial chemicals used in tonne quantities for such things as catalysts for hydrocarbons cracking they are valued in dollars per metric tonnes not dollars per ounce.

Every ounce recovered from waste means hundreds of tonnes of earth under pristine jungle doesn’t get washed into a River system in the third world and that’s a good thing. I was there for a university friend of mine his father owns the mine and I am a geochemistry expert his son is a hydrologist you need both to hydromine.

Some reports tell us that an old-school PC contained an eye-watering $9 worth of gold. But that’s not counting the cost of removing it.

Some other sources estimate that your average computer contains about 1/5th of a gram, or about $12 worth, of gold in them. On the other hand, laptops typically contain about 1/10th of a gram of gold, or around $6 worth.

However, the actual value will depend entirely on the type of e-waste you are looking at. For example, industrial video equipment often has a proportionally higher amount of gold, sometimes above 56 grams per machine.

Need something like this for rare earths extraction

At a 99.9% recovery rate, it would be very nice if it would scale at a reasonable cost.

Lots of gold out there in tailings piles might become valuable.

“Led by post-doctorate researcher Amin Zadehnazar”

Is this in Iran?

What is the net cost of this process?

And how much waste is still left? (99% I bet)

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.