Posted on 01/03/2025 7:11:06 AM PST by Red Badger

Researchers have discovered a chemical-free method for recovering 99.9% of the gold from recycled electronic waste, or e-waste, then using the recovered gold to transform harmful carbon dioxide into useful organic materials.

Led by post-doctorate researcher Amin Zadehnazar, who works in the lab of Alireza Abbaspourrad, a professor of food chemistry and ingredient technology, the process offers a non-toxic method for recovering precious metals from waste material and cleaning the environment.

Organic Matrix Recovers 99.9% of the Gold from Electronic Waste

Specifically, Zadehnazar synthesized a set of organic materials known as covalent organic frameworks linked with vinyl, known for their ability to extract gold ions and nanoparticles found in electronic devices while ignoring plastic and other metals like nickel and copper. When the Cornell researcher applied his synthesized COFs to selected electronic waste materials, including circuit boards with higher amounts of gold than other discarded materials, he found the mix captured 99.9% of the gold and very little of the nickel and copper within the same e-waste.

According to Zadehnazar, whose work took place in the National Science Foundation-funded Cornell Center for Materials Research and the Cornell NMR facility, the COF’s ability to extract and trap gold ions in the matrix not only offers a method for recovering the valuable material but also creates a perfect catalyst for converting carbon dioxide into organic chemicals used in several industrial and commercial applications.

“We can then use the gold-loaded COFs to convert CO2 into useful chemicals,” the researcher explained in a statement. “By transforming CO2 into value-added materials, we not only reduce waste disposal demands, we also provide both environmental and practical benefits.”

“It’s kind of a win-win for the environment,” he added.

E-Waste Programs Have Faced Challenges Staying Green

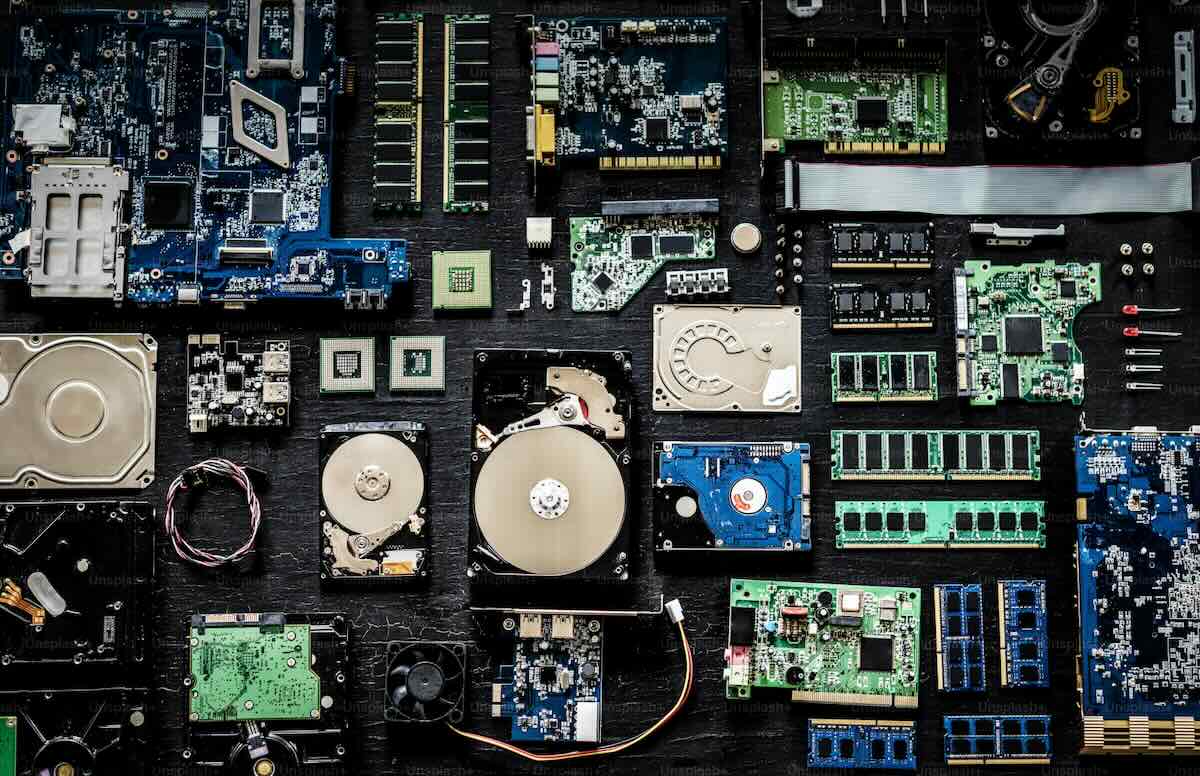

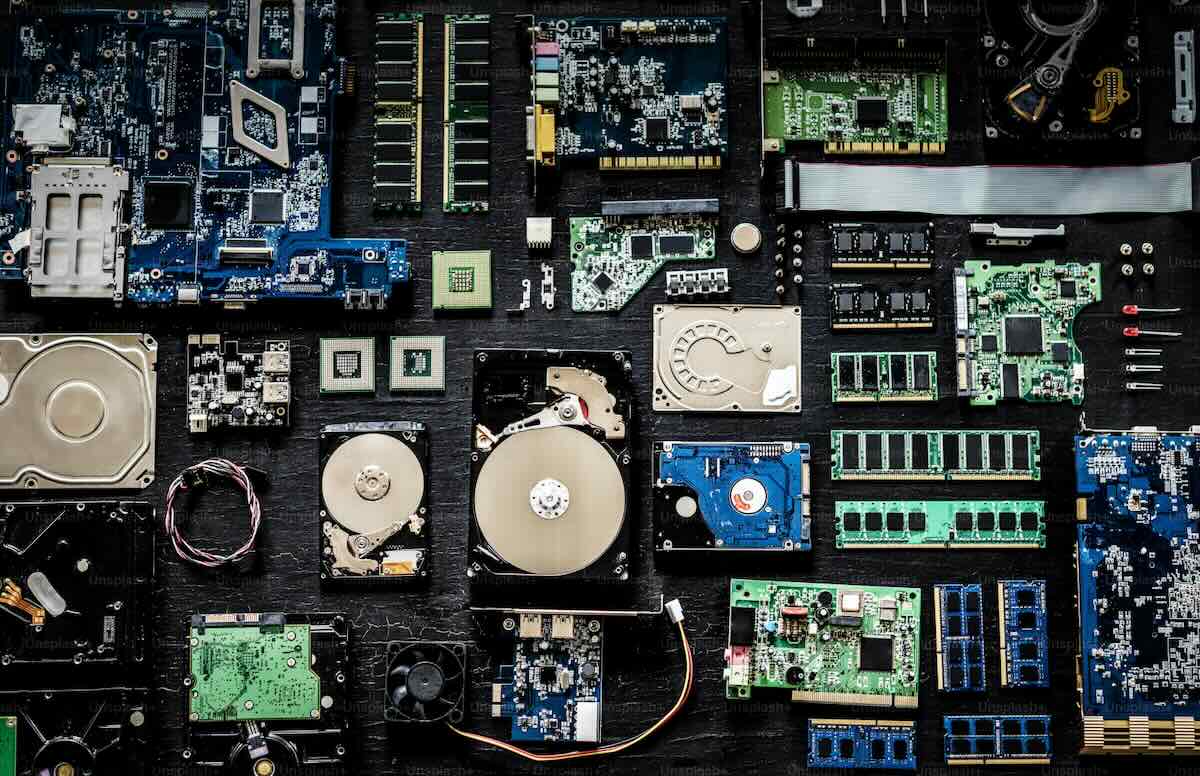

Although several states in the U.S. have electronic waste recycling programs aimed at reducing their disposal in landfills while also recapturing the valuable materials found in the guts of old computers, wires, cell phones, and other electronic devices, most have found it difficult to extract that material in a safe and non-toxic way.

California’s e-waste program began over two decades ago and was initially successful at recovering highly toxic CRT TVs that preceded the flat-screen LEDs sold today. However, that program has faced critical cost overruns as out-of-state televisions are regularly recycled in California. A similar problem plagues the aluminum can recycling program in California, which routinely pays out more money than it takes in due to out-of-state cans recycled locally.

These programs’ efforts to recover precious metals from electronic waste have also faced environmental concerns due to the chemicals used. The process can also be very energy intensive, making a program designed to reduce the carbon footprint a net polluter.

Still, proponents of these programs argue that they are still much more cost-efficient than traditional gold ore mining. According to the Cornell research team, “It’s estimated that a ton of e-waste contains at least 10 times more gold than a ton of the ore from which gold is extracted.” They also argue that given the anticipated 80 million metric tons of e-waste by 2030, “it’s increasingly important to find ways to recover that precious metal.”

Based on his successful tests, Zadehnazar believes his COF-based process offers the first viable solution that works without these chemicals. It also provides a CO2 conversion, making it a key component of a truly environmentally friendly green electronic waste recycling program.

The study “Recycling e-waste into gold-loaded covalent organic framework catalysts for terminal alkyne carboxylation” was published in Nature Communications.

Christopher Plain is a Science Fiction and Fantasy novelist and Head Science Writer at The Debrief. Follow and connect with him on X, learn about his books at plainfiction.com, or email him directly at christopher@thedebrief.org.

The gold that I see in the picture is on the connectors.

These connectors could be sawed off before further processing.

“And how much waste is still left? (99% I bet)”

Copper will be needed for the leftists’ EV schemes.

“Need something like this for rare earths extraction”

Whole motors could be reused.

Smaller rare earth-containing components could be industrially cut off using AI guided robots.

“Is this in Iran?”

I suspect Ithaca, NY:

“Cornell Center for Materials Research”

I tried once crushing the chips, then panning the residue for the gold.

It turned out to be a big waste of time and effort. Wasn’t worth it.

OK ... i skimmed the full paper looking for the catch ... amongst others, was this one:

“Metal flakes were removed from an end-of-life CPU board by mechanically scraping the components”

not very scalable for railroad cars of scrapped electronics, huh?

and then of course there was the complex and expensive chemical method used to put the mechanically scraped gold in aqueous solution ...

and of course there was the complex and expensive chemical method to make the capturing matrix in the first place ...

and finally, looks like it takes ANOTHER complex and expensive chemical process to release the gold ions from the complex and expensive matrix ...

the whole thing had to be much more costly than mining new gold in the first place ...

and according to AI google, there’s many simpler [and presumably economic] methods of gold recovery:

There are several ways to recover gold from scrap electronics, including:

Acid treatment

Mix hydrochloric acid and hydrogen peroxide in a glass vessel, submerge the circuit boards, and stir daily for a week. The acid will darken and gold flakes will form.

Acetic acid and oxidant

This nontoxic solution dissolves gold from circuits in about 10 seconds, leaving other metals intact.

Protein fibril sponge

Researchers at ETH Zurich created a sponge from whey proteins to recover gold ions from e-waste. The sponge is placed in a metal ion solution to extract the gold.

Cupellation

This process treats ores or alloyed metals at high temperatures to separate precious metals from base metals. The precious metals remain apart while the base metals react and form slags or other compounds.

Other methods for recovering gold from scrap electronics include:

Using a mixture of hydrochloric acid and nitric acid

Using other mild acids

Burning off the gold at high temperatures

Leaching chemicals like a cyanide solution

Smashing the motherboard into bits and dissolving it in an aqua regia bath

The value of the recovered gold depends on its purity and the current market price of gold. A skilled recycler can expect to receive over $10,000 worth of gold from just one ton of computer circuit boards.

“Beautifully written and ready for inclusion into 1) grant applications from the federal government and 2) the prospectus for luring venture capital to invest in Zadehnazar’s BIL’s newly formed LLC.”

well the author is a Science Fiction and Fantasy writer

His grant writers certainly used every “green” buzzword to beg for tax dollars.

People think that this is going to be some lind of gold mine. I read that National Semiconductor’s gold consumption in the 70’s and 80’s (when NS was NS) was about 12 troy ounces, or about a pound. I have equipment made by HP in the 70’s (still works, of course) where the entire PCB was plated in gold. Those days are LONG gone except maybe for the military.

I’ve watched some of those scrapper channels on you tube. They spend HOURS collecting trash to turn in to “treasure” and just guessing it looks like they don’t even make minimum wage. There’s one treasure you can not recycle or save and that is TIME.

Zak Lee.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.