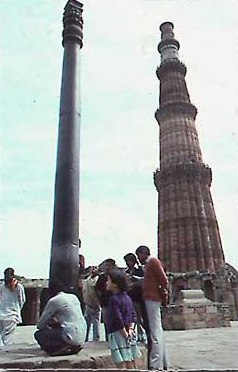

I did a search and found some pictures of it.

The above article is from corrosion-doctors.org website and gives more details about the pillar and the theories about why it's not corroded.

Posted on 03/13/2005 1:55:06 PM PST by blam

Mystery of Delhi's Iron Pillar unraveled

Press Trust Of India

Thursday, July 18, 2002

New Delhi, July 18: Experts at the Indian Instituteof Technology have resolved the mystery behind the 1,600-year-old iron pillar in Delhi, which has never corroded despite the capital's harsh weather.

Metallurgists at Kanpur IIT have discovered that a thin layer of "misawite", a compound of iron, oxygen and hydrogen, has protected the cast iron pillar from rust.

The protective film took form within three years after erection of the pillar and has been growing ever so slowly since then. After 1,600 years, the film has grown just one-twentieth of a millimeter thick, according to R. Balasubramaniam of the IIT.

In a report published in the journal Current Science Balasubramanian says, the protective film was formed catalytically by the presence of high amounts of phosphorous in the iron—as much as one per cent against less than 0.05 per cent in today's iron.

The high phosphorous content is a result of the unique iron-making process practiced by ancient Indians, who reduced iron ore into steel in one step by mixing it with charcoal.

Modern blast furnaces, on the other hand, use limestone in place of charcoal yielding molten slag and pig iron that is later converted into steel. In the modern process most phosphorous is carried away by the slag.

The pillar—over seven metres high and weighing more than six tonnes—was erected by Kumara Gupta of Gupta dynasty that ruled northern India in AD 320-540.

Stating that the pillar is "a living testimony to the skill of metallurgists of ancient India", Balasubramaniam said the "kinetic scheme" that his group developed for predicting growth of the protective film may be useful for modeling long-term corrosion behaviour of containers for nuclear storage applications.

They don't make 'em like they used to.

And this today:

More research needed on Delhi Iron Pillar: experts:

[India News]: New Delhi, Mar 13

The Delhi Iron Pillar, which has withstood corrosion for over 1,600 years, continues to attract the attention of archaeologists and scientists who want to undertake a systematic study to unfold the secret behind its strength.

A panel of scientists from across the country has recommended that the Government allow research on the pillar, a symbol of Indian metallurgical excellence, to ascertain its age, as well as for conservation of its underground part and the passive film that has preserved it through the ages.

"The Archaeological Survey of India has agreed to allow the use of well-established non-invasive techniques to ascertain as to when was the pillar built and its material aspects. But the efficacy of the techniques should be established by testing other ancient iron objects such as Iron Pillar at Dhar and Iron Beams at Konark," Director, Indira Gandhi Centre for Atomic Research, Dr Baldev Raj, who was a member of the panel that made the recommendations, said.

The panel had gathered here to review the status of scientific research on the pillar and make recommendations to the Government to initiate systematic scientific studies to gain more information about it.

Earlier studies, beginning in 1961, have thrown some light on the composition and the microstructure of the "rustless wonder", but difference versions exist on the scientific dating of the pillar, Professor R Balasubramaniam, a scientist at IIT Kanpur who has conducted extensive research on the pillar, said. PTI

Good Lord, this technology has been around for over 1600 years? To think how much rust proof steel could have saved in money, time, and labor. Staggering.

This is not a union friendly material.

I have a photo of the iron pillar from my visit to Delhi but don't know how to post it.

"Good Lord, this technology has been around for over 1600 years? To think how much rust proof steel could have saved in money, time, and labor. Staggering."

I just thought the same thing - rust proof! All these years, the technology was lost. How many other secrets have been lost to us, and are just waiting to be rediscovered?

Not hard to understand. The phosphorous that caused the beneficial reaction (probably electrochemical to produce the necessary hydrogen--but the article doesn't say--consider that "chemical speculation") is distributed uniformly throughout the iron matrix due to the way the iron was made. The film will only form on the surface exposed to moisture and oxygen, which is only (but everywhere) on the surface of the entire pillar from top to bottom.

I did a search and found some pictures of it.

The above article is from corrosion-doctors.org website and gives more details about the pillar and the theories about why it's not corroded.

My Granddad passed away last year at age 98. He was at turns a foundry worker, machinist, master patternmaker and coremaker. He claimed that the "old timers" (folks who were 50 or so in the 1920s) told him that there had once been a process to harden copper so as to use it for tools, etc.

One wonders if the ancient Egyptians (who used copper tools to cut the stone used in the Pyramids) knew of this process.

There was probably a scroll or three on this in the Great Library of Alexandira before it was destroyed.

Before everyone goes all ga-ga over the skill of the ancients, consider this. The reason that phosphorous is eliminated by modern metallurgical process is that it causes the iron to be exceedingly brittle, thus rendering it unsuitable for use as a structural material or say a cannon barrel. Perfectly acceptable for a decorative column or ballast weight however.

Regards,

GtG

I once owned a copper bladed knife made by the Dawson Hardened Cooper Cutlery Co. I think they were in business in the 20s.

The knife turned out to be valuable once it left my hands.

:(

mc

Rome concurred the world with bronze swords. Iron still beat the heck out of bronze when it became generally available. If you need to harden copper, it may be alloyed w/ beryllium, which also makes the material "non-sparking". A very useful characteristic in some circumstances.

Regards,

GtG

Forget the details, where can I get lawn furniture made from this iron?

And, will continue to grow at a decreasing rate as less iron is exposed to the ambient oxygen.

Again, too many details! I have but one question. Can it be put to use as lawn furniture!?!? ;)

And Parkerizing is the formation of basic iron phosphate on a surface to protect it from rusting. Not very "New", but loading the iron with phosphorous and leaving it in the rain is a tedious way to do it. Plus, as you say, the physical properties of the iron would be horrible.

FYI: The oldest bronze smeltering site in the world is in Thailand.

And that, sir, is why you're such a fine wizard.

Of course, had our ancient Indian metalmen been more patient, and added the charcoal somewhat later in the process, they'd have gotten steel....

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.