Posted on 10/14/2021 6:17:45 AM PDT by Red Badger

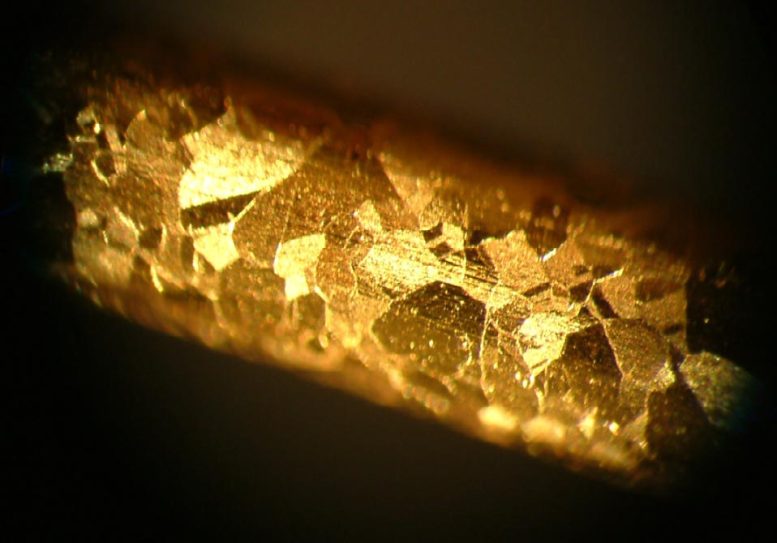

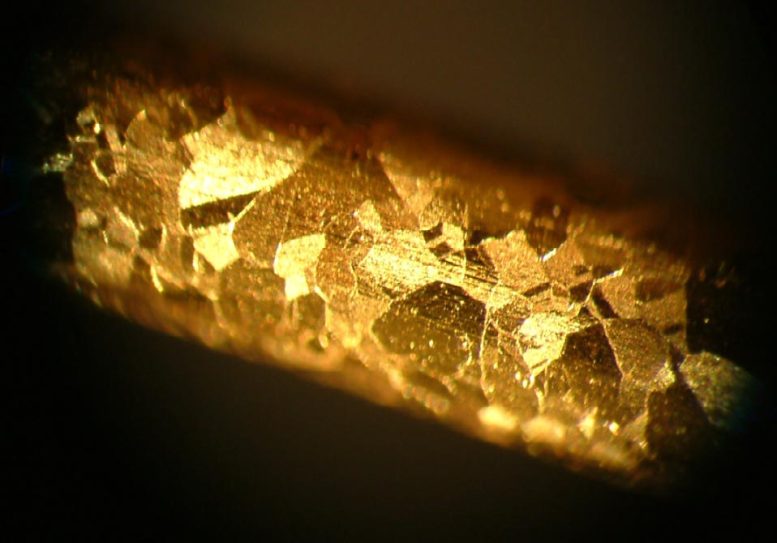

Gold. Credit: Robert von Bonsdorff/Aalto University

Study shows new chloride-based process recovers 84% of gold compared to the 64% recovered with traditional methods.

Gold is one of the world’s most popular metals. Malleable, conductive and non-corrosive, it’s used in jewelry, electronics, and even space exploration. But traditional gold production typically involves a famous toxin, cyanide, which has been banned for industrial use in several countries.

The wait for a scalable non-toxic alternative may now be over as a research team from Aalto University in Finland has successfully replaced cyanide in a key part of gold extraction from ore. The results are published in Chemical Engineering.

Traditionally, once gold ore is mined from the ground, it’s crushed to a powder and passed through a series of tanks in a process called leaching. Cyanide is then used to separate the gold from the ore into the leached solution.

With the new process, the leaching and recovery process is done with chloride, one of two elements in table salt.

“Until now, no one has developed a good method for recovering small amounts of gold from industrial chloride solutions,” says Ivan Korolev, a researcher on the project and doctoral candidate.

“With our process, the amount of gold we’ve been able to recover using chloride is as high as 84%. In comparison, using the standard cyanide process with the same ore yielded only 64% in our control experiment,” he explains.

Called electrodeposition-redox replacement (EDRR), the new process combines the best of two common methods for extracting leached gold: electrolysis, which uses electric currents to reduce gold or other metals present in the leaching solution, and cementation, which adds particles of other metals to the solution to react with the gold. Professor Mari Lundström and University Lecturer Kirsi Yliniemi, from Aalto University’s School of Chemical Engineering, are behind its development.

“With EDRR, we apply short pulses of electricity to create thin layers of metal – in our case copper – on the electrode and cause a reaction that encourages gold to replace the copper layer by layer,” says Korolev. “The method has low energy consumption and doesn’t require the addition of any other elements.”

Industry-level collaboration The research was conducted as part of a broader EU sustainability project called SOCRATES, and the work was done in collaboration with Finnish mining-technology giant Metso Outotec. Most of the experiments were performed at the company’s research center in western Finland.

“Collaborating with Metso Outotec allowed us to develop the method in a way that’s much closer to real-world implementation,” says Korolev. “We started with about 9% recovery, but it then grew to 25%, and soon we were hitting 70% — sometimes we even achieved close to 95%.”

“It’s one thing to do an experiment like this on a small scale, but nobody had ever done it at the scale that we have done. We showed that even though our method is still really new, there is a lot of potential for making it a successful alternative to the traditional industrial process,” he says.

“Until now, no one has developed a good method for recovering small amounts of gold from industrial chloride solutions.” — Ivan Korolev

“The extraction methods of the past have always left some valuable metals behind. Now, as demand for metals grows all the time, even these small amounts are important,” he says. “I think we can still increase the yield with our EDRR technology. Perhaps we cannot reach 100%, but I believe we can hit the 90% mark or more.”

“It would be great to see a mining company interested in this technology and willing to test with their ore on site.”

Korolev has a very personal interest in the project too. Born in the Siberian mining town of Kemerovo, he grew up seeing both the positive and the negative sides of the industry. When studying mining engineering – first in Russia and then in several European universities – Korolev became interested in metallurgy and the recovery of waste materials.

“The extraction methods of the past always left some valuable metals behind. Now, as demand for metals grows all the time, even these small amounts are important,” he says. “I think we can still increase the yield with our EDRR technology. Perhaps we cannot reach 100%, but I believe we can hit the 90% mark or more.”

Reference: “Electro-hydrometallurgical chloride process for selective gold recovery from refractory telluride gold ores: A mini-pilot study” by Ivan Korolev, Pelin Altinkaya, Mika Haapalainen, Eero Kolehmainen, Kirsi Yliniemi and Mari Lundström, 8 September 2021, Chemical Engineering.

DOI: 10.1016/j.cej.2021.132283

3400 psi of HCL dumped into his face.

With more presence of mind that I would have ever credited him with, he slammed the valve shut, and managed to get the door to the gas room open and stumble out into fab before he collapsed.

I missed all the excitement, the place sucked so bad I was out on an interview that day.

The upshot?

Corporate in NY sent a senior safety officer to talk to us.

• Be careful. If you get killed it could cost the company $50,000, and if -God forbid- you get injured it could cost the company $500,000.

• We're not going to teach you first aid because that would take too long. (I very nearly slapped my Red Cross First Aid instructor's card on the table).

• We're locking up the Scott Airpacks.

• Call the ERT and they'll take care of everything. (They were called, and showed up half an hour later)

The message came through loud and clear.

My interview produced a good job offer, which didn't require a second's thought to accept.

And Bruce? I lost touch with the people at that company, but years later I saw him jogging while coming back from my first day's lunch at yet another company, Hughes Newport Beach, my first day there, his last, didn't get to do much catching up, but it was good to see him alive and well!

Such utter disregard for safety was not uncommon when I started in the industry, 40 years ago. It’s less so, now... I hope. But, I think it’s still out there, in some places. It’s rampant in China still.

My issue happened when we were running a VCM plant. We had put a leak control device on a line to seal a leak. It was the kind of device we used often. We put a metal box around a pipe, sealed it up, then pumped it full of a high pressure sealant material. But this, time.... we screwed up the design. It was installed on a U-tube section of pipe... with the U, INSIDE the box. None of us geniuses looked at the design and saw the problem on paper.. (We’re CHEMICAL engineers, not MECHANICAL!)

When we started pressuring the box with the sealant, there was NOT an equal force on both sides. The box started moving OFF the U. Not sure I’m describing it well... a picture would make it obvious. The box moved until it hit a 2” blinded flange. And then, it SHEARED the flange completely off. That left a 2” open pipe, with 100 psi high purity Anhydrous HCL dumping right on top of our control room. The entire 150’ tall HCL/VCM splitter emptied it’s contents.

The control room was pressurized, but... not air tight. We had enough leakage that we couldn’t stay in there. We had a handful of fresh air supplied mask in the control room. Enough so a few operators could stay inside to safely shut the plant down. The rest of us (~ 10 people) put on escape mask and headed out to the parking lot to look for clean air. We already couldn’t see. We felt out way along the familiar hallway, and out into the parking lot.

When we got there, the clear air felt WONDERFUL... but, half of us had inhaled enough to be throwing up. I didn’t. But, I had ZERO sense of smell or taste for almost a week.

In hindsight, it was a really stupid mistake. But, we had a dozen people who signed off on the design. They couldn’t fire us all. This was at Dow Chemical, by the way. They tried hard to do things the right way. This one just slipped by us.

On a straight piece of pipe the 'thrust' (actually the absence of a wall to push on where the pipe is) is equal and opposite. The U has both 'nozzles' pointed the same way (more area on the non-pipe side).

Hmmm, a larger pipe on one end (i.e. a reducer in the box) would also move when pressurized, right?

What do I win?

My friend's HCL surprise was in early 1977. The semiconductor industry's safety awareness did improve dramatically over time...

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.