Posted on 10/26/2025 6:23:59 AM PDT by Red Badger

Whatever else its faults — and it has many — one of the good things you can say about Amazon is that it employs a whole heck of a lot of American workers.

At least, it does for now.

CNBC reports:

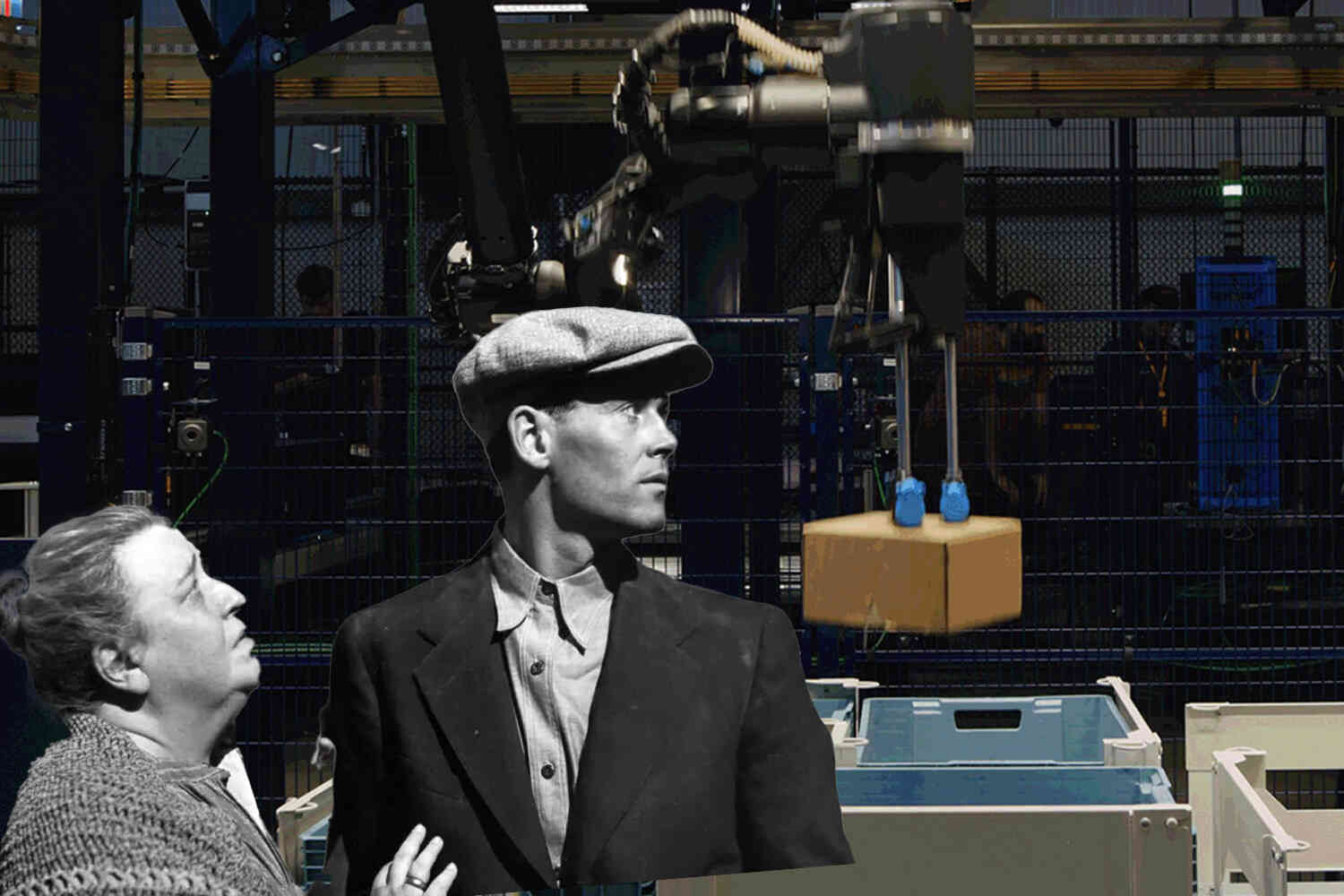

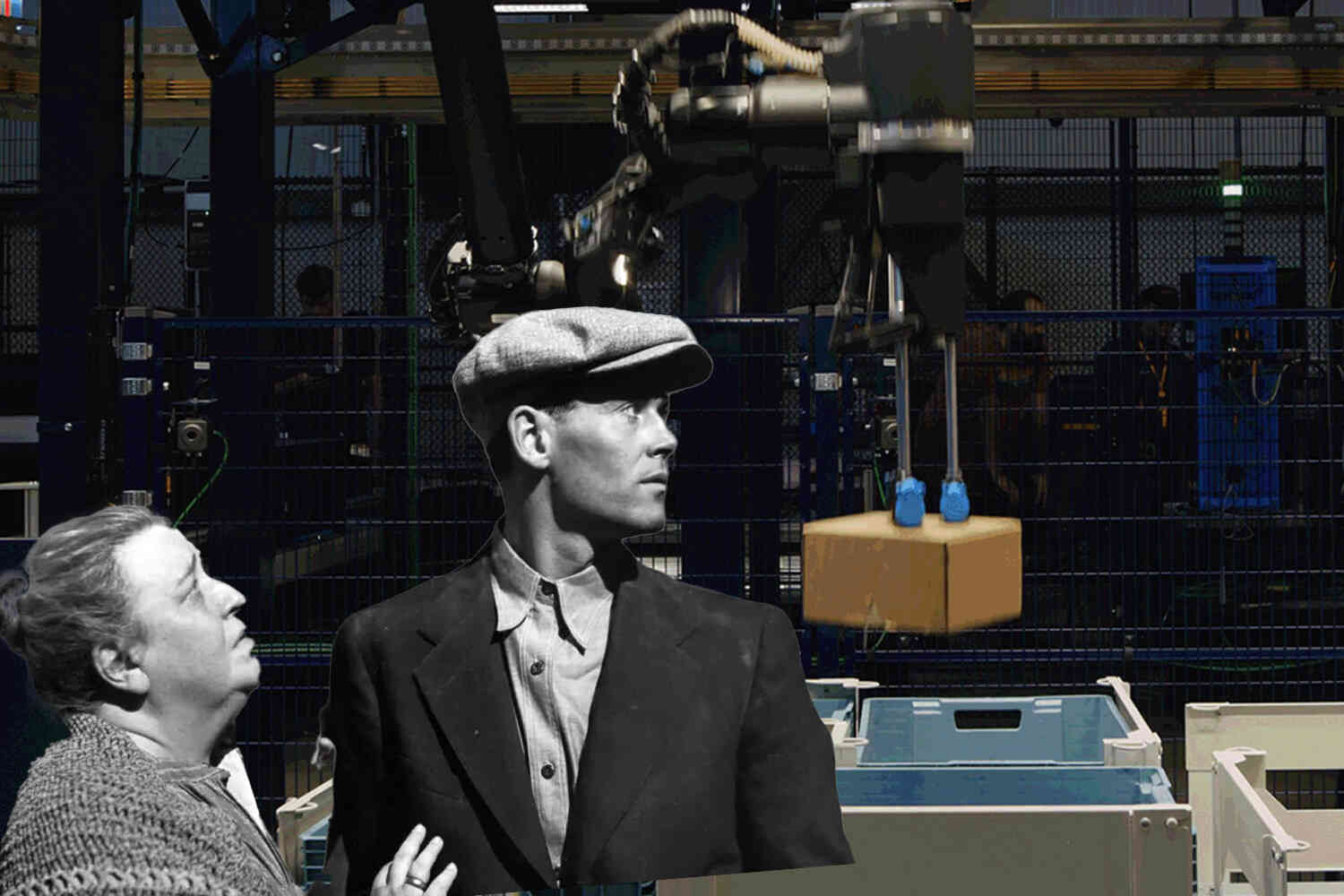

Amazon on Wednesday unveiled a new robotic system that's capable of performing multiple tasks at once in the company's warehouses.

The system, called Blue Jay, is made up of a series of robotic arms that are suspended from a conveyor belt-like track. Those arms are tipped with suction-cup devices that allow them to grab and sort items of varying shapes and sizes.

"Grabbing and sorting items of varying shapes and sizes" is of course like 90% of what an Amazon warehouse worker does.

To be sure, Amazon already has robots doing a lot of suction-cupping and sorting in its warehouses. But, per the New York Times, Blue Jay is part of an ambitious new bid by the company to deploy vast armies of automated workers and thus replace the flesh-and-blood humans that may get hired there in the future:

Executives told Amazon's board last year that they hoped robotic automation would allow the company to continue to avoid adding to its U.S. work force in the coming years, even though they expect to sell twice as many products by 2033. That would translate to more than 600,000 people whom Amazon didn't need to hire.

Now, according to materials published by Amazon itself, the new "Blue Jay" robot doesn't look all that different from the current set of Terminators the company deploys in its warehouses:

But the robot is "already able to pick, stow, and consolidate approximately 75% of all the various types of items we store at our sites," and the company says it developed the tech behind it much more quickly than previous innovations:

Blue Jay's development moved from concept to production in just over a year — a process that formerly took three or more years for earlier Amazon systems like Robin, Cardinal, or Sparrow. The reason: Years of trial-and-error were condensed into months of development thanks to advancements in AI.

Ahh, yes. AI.

According to the company, Blue Jay is "like a juggler who never drops a ball" and "like a conductor leading an orchestra, with every motion in harmony." That sounds a whole lot heck of a lot like "perfect non-human worker that will replace a butt load of human workers" to me.

Not a great sign if you work at Amazon, I'm afraid.

Though a lot of food is planted and/or harvested and/or processed by 'robots,' too! Many crops around here are planted using GPS and then harvested the same way. Eventually we may not even need a human Farmer! :(

Or Air Conditioning in summer or heat in winter.................

trailer lockers

Some of the locker cabinets might be swing (or slide) out to maximize the number of lockers.

These would be opened by like a Greyhound luggage locker is by the customer using a code.

All the lockers would have to be accessible. The stuff for wheelchair customers would be loaded in lockers accessible by a person in a wheelchair.

The trailers might be parked on site for two or three days before being brought back to the warehouse for restocking. A storage fee might be charged after so many days if the locker isn’t opened.

The system could allow for returns using an emptied locker.

I have 16 glass jars of spaghetti sauce coming, being a long time user of Amazon, I’m wondering what it will look like when it arrives.

I’m going to buy a few White ones to work like slaves on my little ranch.

I wouldn’t want Jesse Jackson getting mad at me.

Detroit workers noticed it first years ago.

I was after 3 glass jars of MILD Indian butter chicken sauce, not available at any Asian or American grocery around here. I do extensive taste tests on all brands of any new something or other, and then become fixated on our top choice.

They came all packed loose together. Not good.

What IS good is Amazon refund policies.

I’ve come to assume brain dead packers and take the cost hit on buying one by one when it MUST be Amazon and it IS fragile.

Best of luck with your 16 jars. I’d cross my fingers for you but touch typist here. Let me know how it goes.

“FRAGILE” —

It’s the shipping equivalent of

“DO NOT WALK ON THE GRASS”

It’s just asking for a beatdown.

Reducing packaging costs and waste is important too, and packaging and safe shipping should be designed to function starting from each factory.

I’ve seen it all with their and Walmart’s shipping, one never knows, until it arrives.

It does seem to me though that in recent years the ridiculous and massive catastrophic packing debacles are getting more rare.

For example 2 extra large glass jars of sauce, heavy canned foods like a case of canned stew, 20 loose cans of soda pop and a 5 pound bag of flour, loose cans of vegetables and other items all thrown together loosely into a very oversized box, that was quite a box to open after it crossing the country.

You will always need a human farmer looking at the dirt with imagination and ambition.

AI robots will end up irrigating with Brawndo.

Health and Workers Comp Insurance costs should virtually disappear...............

Health and Workers Comp Insurance costs should virtually disappear...............

Extremely unfortunate. Also extremely funny. So very sorry for your box opening area.

I think there’s a reason Costco sells gas; it brings customers close to the store.

Perhaps Walmart should sell gas, directly or indirectly.

Here they do. Sam’s is right next to our Walmart with a gas station in front...............

AI robots will end up irrigating with Brawndo.

It’s got electrolytes!

Maybe the mechanical delivery equipment will refrain from putting the boxes in front of the door, obviating the need to bring it in through the garage door.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.