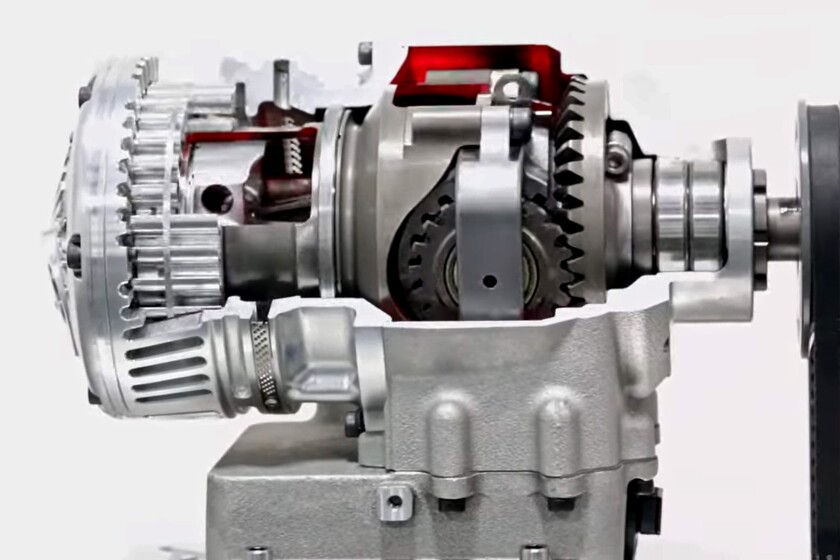

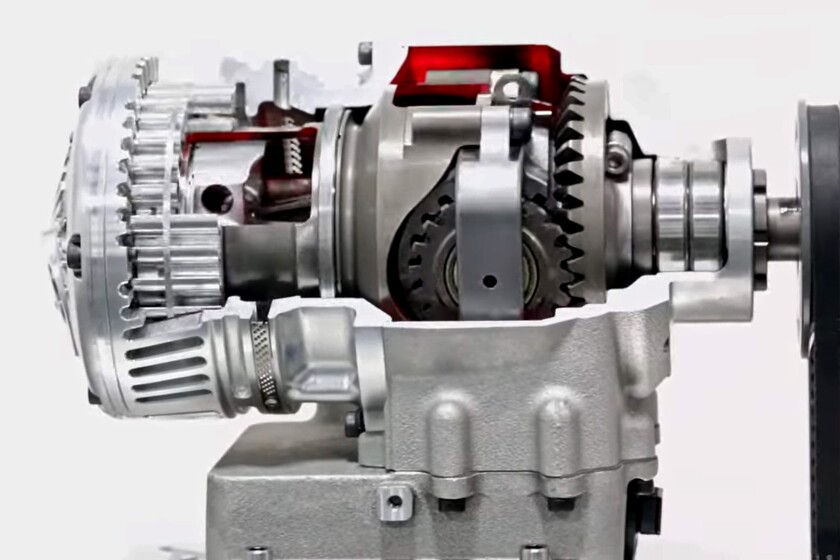

Avadi MA-250 engine cutaway side view - Avadi

https://www.avadiengines.com/overview

Posted on 06/10/2024 1:01:18 PM PDT by Red Badger

An innovative new combustion engine eliminates half the guts of a traditional engine, and uses a fascinating internally-rotating piston and sleeve arrangement, making it lighter, simpler and more efficient while still making strong power and torque.

Michael Arsenaeu designed the Avadi engine 20 years ago in the hopes of creating an entirely new engine design to be efficient as well as reduce emissions. In 2015, Avadi began the build and development.

Rotary might be a good name for this sort of engine, if the name wasn't already taken. Everything inside the crankcase rotates, but unlike a Wankel-style rotary engine, this design uses a piston with two connecting rods that have a scissor-like movement attached to pinion gears at the back of the engine.

All of this rotates on a fixed ring gear connected directly to the output shaft. It uses a valve disk that also rotates to complete a four-stroke cycle of intake, compression, combustion, and exhaust as everything rotates internally.

It's dizzying. Check it out:

VIDEO AT LINK......

According to Avadi's website, "two connecting rods and their corresponding pinion gears reside in what we call a 'halfshaft.'... the halfshaft can be likened to the heart of the Avadi design, it is essentially the housing where up-and-down piston motion is translated to rotational motion."

Unlike a Wankel rotary engine, the Avadi eliminates the traditional crankshaft entirely, as the cylinder and piston rotate within the case during its stroke. Everything very much looks and functions like what you'd see in a rear differential – if differentials had pistons connected to planetary gears.

Looking at it in motion does make me wonder if the low mechanical advantage from the connecting rods to the pinion gears might constitute a long-term reliability issue from the torsion factor on a narrow, short stroke.

(Excerpt) Read more at newatlas.com ...

Avadi MA-250 engine cutaway side view - Avadi

https://www.avadiengines.com/overview

Does it use AC or DC?

ICE....................

Very cool design but you cannot add more pistons inline, so you’re going to have to increase your mechanical systems and/or the equivalent to you crankshaft or transfer cases if you want more cylinders.

I would say that is better candidate as the gasoline side power source for electrical generation in a gas-electric hybrid than it is for mechanical force generation in a gas-only vehicle.

Pretty cute, sending link to my friend Tom to figure out where to put the turbos...

https://nelsonracingengines.com/

Seriously, though, what practical uses, especially once it gets all of the emissions components added? And how noisy? Will it run a generator? Put in trunk of Tesla to recharge it on the road?

Package and sell it as a build your own engine, especially tied to a generator. That looks like it would be a fun and challenging kit build.

I just dont see the advantage of this thing.

Compare the parts count of a one cylinder engine to what is in this engine.

well very much smaller. maybe they want to put one on each wheel :).

sounds like a wankel engine. there have been a lot of variations on this engine over the years.

“sounds like a wankel engine.”

Not even close. This uses the typical 4-stroke piston.

Does not look scaleable.

There are several of these Internal Combustion engines that are small, light, and power dense for their size, but not really scalable to larger engines. And they're incredibly expensive to manufacture. LiquidPiston is another.

The anticipated use for these small, light, and powerful engines is to power military drones.

Good point. If I understand you correctly, we’re essentially talking about somehow adding multiple engines as a way to increase output. OR...making the same thing but bigger. I can see a decreasing weight to output curve on that idea, though. Maybe the same with the former.

Then again, in the video they talk about using a scale large enough to drive cargo ships and trains. Hmmm...

Am also wondering, what exactly are the emissions? Does it/will it need a catalytic converter and if so, how much HP will it rob?

If it really is great, I’m sure the government will figure out a way to F it up.

Go to the article’s site and look at the video. It’s little like a Wankel.

“I just dont see the advantage of this thing”

Weight is one. I think the article said it weighs around 1/3 of the Honda GX-240 engine used in lawn equipment and has higher output also. What they end up doing with the valve train design is going to be make or break — rotary valve or what. Again, from memory, I believe the prototype rotary valve design had insurmountable flow problems but my 1968 Yamaha 100 thought it flowed fine, just fixed timing.

“It’s little like a Wankel”

It looks like a Wankel inside a differential.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.