Posted on 06/12/2025 6:17:57 AM PDT by Red Badger

This innovation could reduce weight in various applications, including electric vehicles and spacecraft, without sacrificing performance.

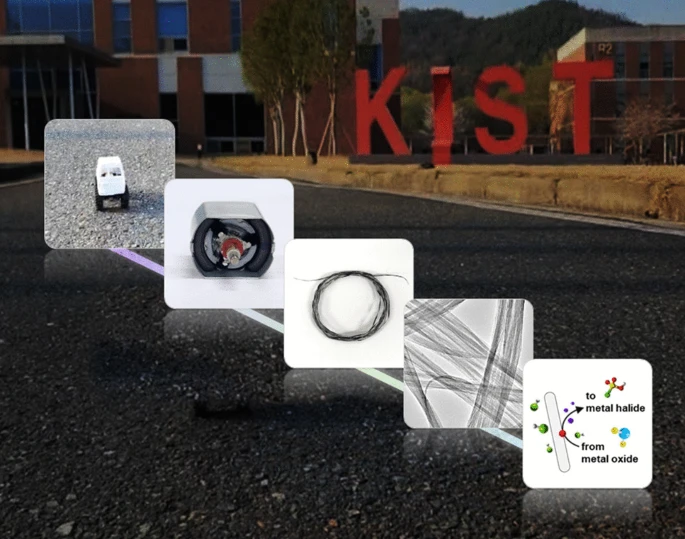

The researchers tested the metal-free motor in a scale model car on asphalt roads. - KIST

========================================================

Researchers in South Korea have developed the world’s first fully functional electric motor constructed entirely without metal components.

This advancement, utilizing carbon nanotubes (CNTs) instead of traditional copper coils, represents a significant step toward ultra-lightweight transportation systems. The motor exhibits a 133% improvement in electrical conductivity and is 80% lighter than conventional designs.

“Whether it’s electric vehicles, drones, or spacecraft, a common technical challenge for future transportation is lightweighting. Reducing the weight of a vehicle not only reduces energy consumption, but also increases battery efficiency and increases range,” said the researchers in a press release.

The motor, developed by a team at the Korea Institute of Science and Technology (KIST), operates effectively and has been shown to power a toy car at speeds exceeding half a meter per second.

“By developing a new concept of CNT high-quality technology that has never existed before, we were able to maximize the electrical performance of CNT coils to drive electric motors without metal,” said Dr Dae-Yoon Kim of KIST.

This innovation holds potential to reduce weight across various applications, from electric vehicles to spacecraft, while maintaining performance.

Overcoming purity challenges

“CNTs are one-dimensional tube-shaped nanomaterials with carbon atoms arranged in a hexagonal honeycomb structure, which are known to be much lighter than ordinary metals, while at the same time possessing excellent electrical conductivity, mechanical strength, and thermal conductivity,” added the researchers.

This development was made possible by a new purification process that solves a long-standing challenge of achieving the purity needed for carbon nanotubes to replace copper. By employing the purification method, called the LAST (Lyotropic Liquid Crystal-Assisted Surface Texturing) process, researchers removed metal impurities that have historically affected nanotube technology while preserving the tubes’ electrical properties.

Electric motor coils conventionally use copper due to its high electrical conductivity. However, copper’s density, at 8.9 grams per cubic centimeter, contributes significantly to overall system weight. Carbon nanotubes offer comparable conductivity at 1.7 grams per cubic centimeter, providing a potential for reducing motor weight by more than 80%.

The main challenge has been contamination. During production, metal catalyst particles become embedded in the carbon nanotubes, which degrades their electrical performance. The KIST team’s method, called the LAST (Lyotropic Liquid Crystal-Assisted Surface Texturing) process, uses principles similar to the liquid crystal technology found in LCD screens.

By dissolving the nanotubes in chlorosulfonic acid, the researchers created a liquid crystal state where the tubes self-align. When this solution is exposed to water, it generates hydrochloric acid that removes the iron catalyst impurities while leaving the carbon nanotube structures intact. This process reduced metal contamination from an initial 12.7% to less than 0.8%.

Performance metrics and demonstrations

The purified carbon nanotube cables achieved an electrical conductivity of 7.7 megasiemens per meter. When built into a motor, the specific rotational velocity—a measure of performance per unit weight—was 1.06 times lower than an equivalent copper-based motor. The motor also operated continuously for 60 minutes under various power loads.

The team built a scale model car powered by their metal-free motor and tested it on asphalt roads. The vehicle traveled 10 meters in 25 seconds. While copper-based motors achieved higher absolute speeds in the tests (1.35 meters per second compared to 0.52 meters per second for the nanotube version), the carbon nanotube wires weighed 78.75 milligrams, significantly less than the 379.08 milligrams of equivalent copper wires.

“Based on the innovation of CNT materials, we will take the lead in localizing materials such as conductive materials for batteries, pellicles for semiconductors, and cables for robots,” concluded Dr Kim.

Why is the photo resolution so bad, even for it’s size?

That sure looks like copper windings around the shaftlike part of the second inset image.

Maybe it’s just a coincidence of color though.

The carbon nanotubes still have to be insulated from each other just like wires, so they used the same lacquer that conventional motors use...............

Now, will it scale up and be reliable and affordable?

Failure to do anything about "depth of field". The focus point can be in only one plane. There are many in that photo, so many that the camera focused somewhere that wasn't any of the three planes of interest.

Photography really isn't "point and click".

How is a “tube” one dimensional?

At least, they defined what CNT is on first usage. Pet peeve of mine when writers don’t do that.

https://link.springer.com/article/10.1007/s42114-025-01302-4

https://link.springer.com/article/10.1007/s42114-025-01302-4

I don’t see anything here about its end-of-life (recyclability and such). Does it burn? Not interested in the functional equivalent of carbon fiber wind turbine blades! Recycling composites is usually a bear.

It looks like they used the tiniest radio-controlled car in the world for the experiment! Asphalt road? For weeble-mobile, that’d be like off-roading on an ancient lava flow!

It looks like they posed three photographs on a counter top. Each photo was taken without regard to "depth of field", then the individual prints were photographed as a group again without such regard.

Looks like someone needs needs to learn how to to "image stacking" with Photoshop.

In the olden days we could focus on the center one, stop down to f32, and use a slow shutter speed.

Looks like a red plastic washer to hold the commutator together.

and that shaft sure looks metallic

No metal car?

Neodymium magnets are 18X stronger than conventional iron magnets, and about 1500X stronger than carbon based magnets.

No, they are not going to have a non metal car. Not so long as neodymium is in the alternator, as it better be. Or in the motors that move the car if it is EV.

HA! I was wondering if anyone else noticed that.

Tiny South Korea discovers something no American researchers have, in spite of academia’s claims that federal funding for the oh so important research they are doing is so necessary. In fact, the priorities of all federal funding for research must be re-examined and many current wasteful grants and their “research” killed.

Koreans don’t have a ‘diversity’ mentality.................

Back in the 80’s worked for a Swiss owned company making precision servo motors ( in America). Reducing weight, better efficiency, and lowering cost were the engineering groups main goals. Things like splining shafts where the laminate stack seated, coming up with lighter insulating materials, and finding the most efficient machining steels ( American made at that time Republic leaded 1040). The good old days when things were being made in America.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.