Posted on 04/07/2020 5:43:36 PM PDT by NoLibZone

A team at MIT developed a ventilator that could be built with $100 dollars worth of parts — a fraction of the average $30,000 cost most machines take to manufacture, according to a report by SciTechDaily.

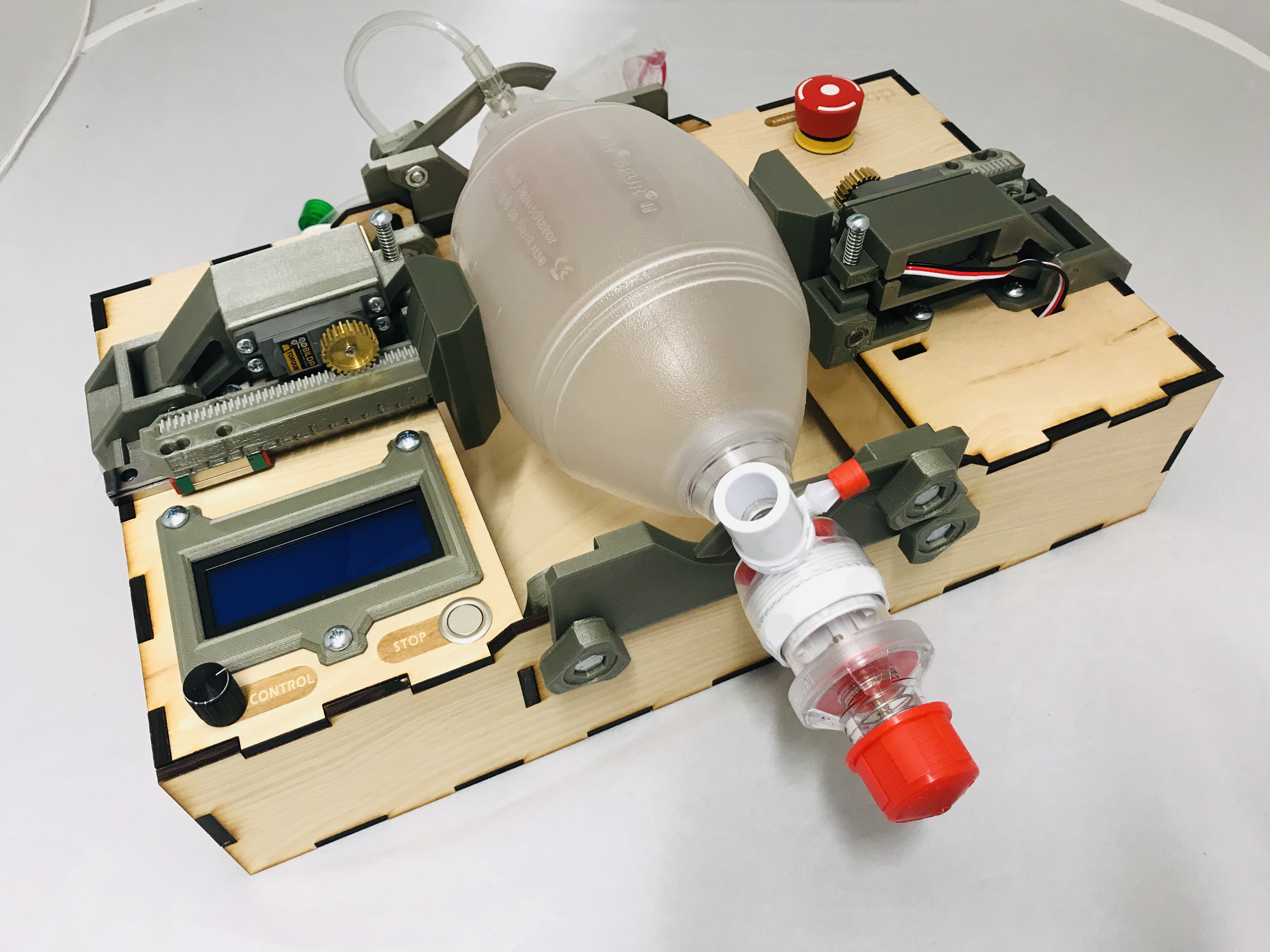

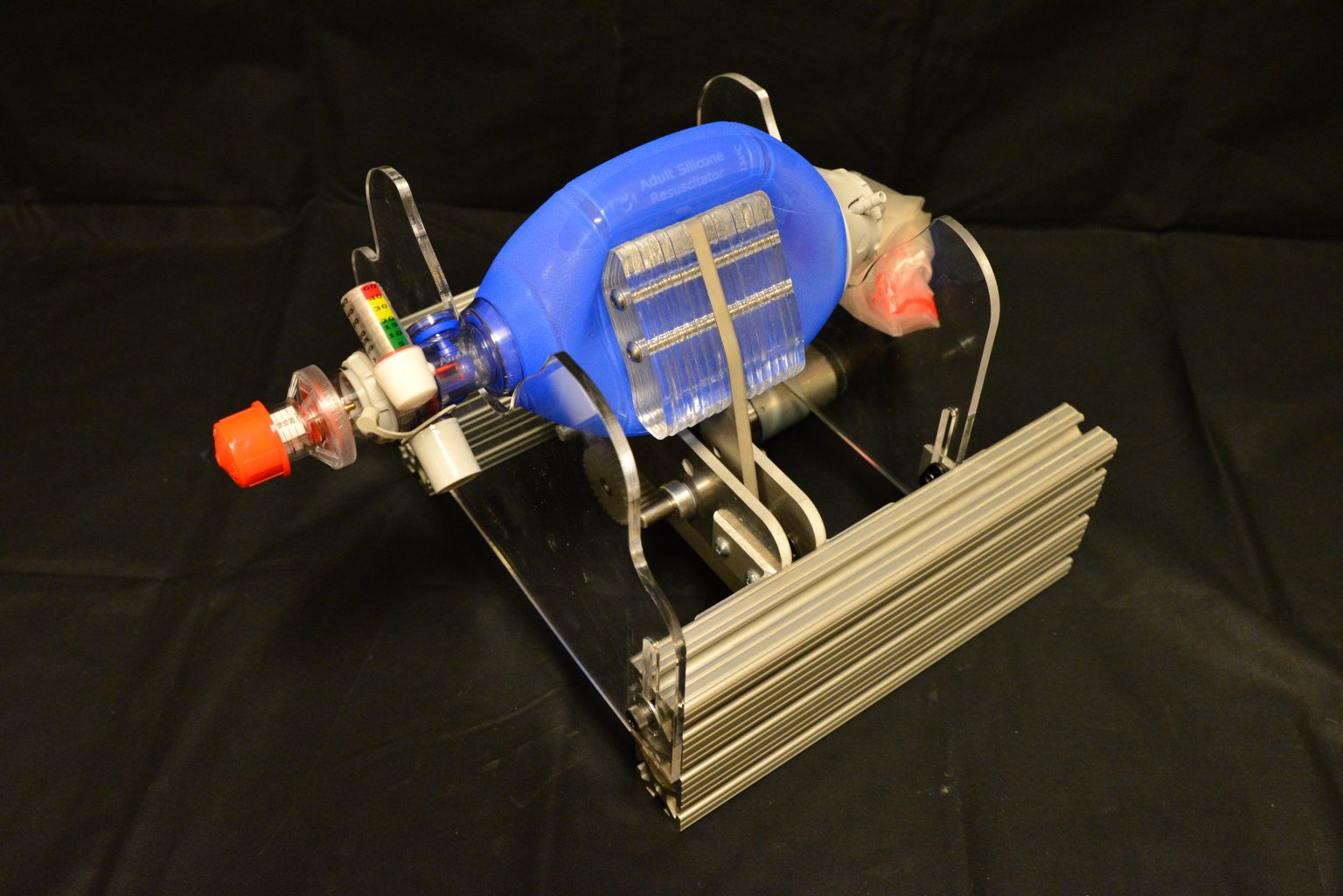

The innovative design of the machine relies upon a bag-valve resuscitator, a piece of equipment found in bulk at most hospitals to help patients breathe, the report said.

Ventilators are one of the most in-demand medical items at the moment amid a worldwide shortage due to the coronavirus.

The team, MIT E-Vent, which consists of doctors, engineers, and computer scientists, decided to fervently revisit the building of an emergency ventilator machine, which began as a project in an MIT class, SciTechDaily reports.

The bag-valve resuscitator, also known as an Ambu bag, is used by hand to pump air into the lungs of a patient, according to the report. The design of MIT E-vent's machine pumps the Ambu bag mechanically in order to run for days, since just a two-week period could require more than one million cycles of the machine.

While the team plans to publish the design online in order to contribute to a wide-scale ramp-up of the device's production in order to help the worldwide storage, they stressed that the design is not meant for anyone to build — it's intended for experienced clinical engineers to help expand manufacturing, according to the report.

MIT E-vent emphasized the technical nature of the machine, as it must be able to adjust the air and pressure given to a patient to fit their exact needs and must be relied upon to operate continuously since machine failure could be deadly, according to SciTechDaily.

The team is waiting to receive feedback from the US Food and Drug Administration,

(Excerpt) Read more at businessinsider.com ...

Even the $30k ventilator damages the lungs.

I made on today. I used a old hand tire pump and had the wife pump it while I tried it.

Near floated away.

MacGyver could have made one in five minutes from things in the janitors closet.

Another possibility:

This International Group Invented An Open Source Alternative That’s Being Tested Next Week (Mar 18, 2020)

So many people on this thread seem committed to ‘Debbie Downer Negativism’.

This Nation has developed some of its greatest innovations when it has been under severe stress.

It’s easy to sit back and predict the worst outcomes; but it’s nuts to denigrate the people who are trying to come up with solutions.

DC will pay $100,000 each for them.

Its cheap, and it works, and it will not be allowed. Why? Just because... (can’t let college inventors steal the spot light and “beat the system”)

Good on ya MIT!

What about the oxygen input and flow control?

No way they could build that for $100. The e-stop alone is $22.

Cost reduction for medical equipment — talk about a wide open field ...

Methinks this recent ventilator demand will prove to be a misguided overreaction to the point we will be dumping them left and right. The Law of Unintended Consequences goes forth boldly.

2 weeks = 14 days = 336 hrs = 20,160 min = 1,209,600 sec.

Breathing cycles? A lot of short breaths? Perhaps the cost estimates are also a bit off?

Its very simple design. A piston type of design that squeezes and releases the resesitator bag. These boys are brilliant!

Any solution should be utilized only in a healthcare setting with direct monitoring by a clinical professional. While it cannot replace an FDA-approved ICU ventilator, in terms of functionality, flexibility, and clinical efficacy, the MIT E-Vent is anticipated to have utility in helping free up existing supply or in life-or-death situations when there is no other option.

Further, any low-cost ventilator system must take great care regarding providing clinicians with the ability to closely control and monitor tidal volume, inspiratory pressure, bpm, and I/E ratio, and be able to provide additional support in the form of PEEP, PIP monitoring, filtration, and adaptation to individual patient parameters. We recognize, and would like to highlight for anyone seeking to manufacture a low-cost emergency ventilator, that failing to properly consider these factors can result in serious long-term injury or death.

One of the young engineers in the video says $300. That seems more like it.

Of course, that would doable only in a small, lean company without any marketing or sales budget. BOM COGS alone are probably $200. 2X for Overhead and G&A gets you to $400.

“2 weeks = 14 days = 336 hrs = 20,160 min = 1,209,600 sec.

Breathing cycles? A lot of short breaths? Perhaps the cost estimates are also a bit off? “

Perhaps you slept through that portion of your class on ventilator design?

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.