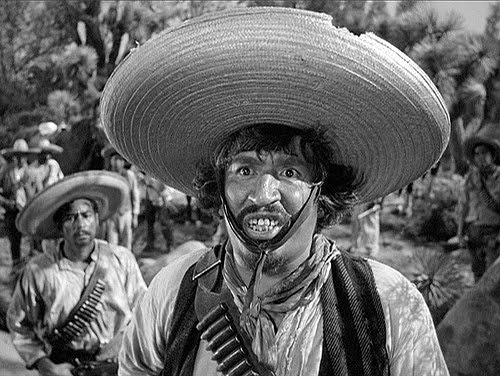

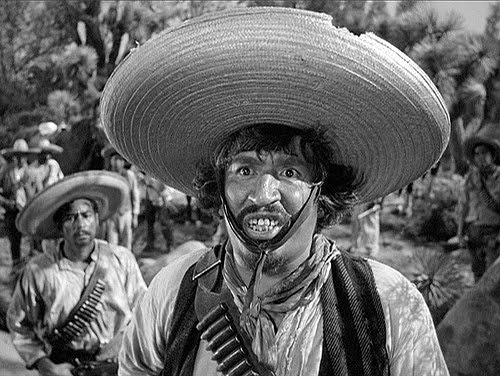

We don need no stinkin' wings!

Posted on 07/10/2019 5:36:43 AM PDT by WhoisAlanGreenspan?

European regulators have ordered inspections on some older Airbus A380 superjumbo airplanes after some cracks were detected in wings on the world's largest passenger aircraft.

The European Aviation Safety Agency (EASA) directive, which formalizes an instruction from the manufacturer itself, covers part of the outer wing on the 25 oldest aircraft, which first went into service in 2007 with Singapore Airlines .

Airbus said the safety of the aircraft was not affected.

"We confirm that small cracks have been found on the outer rear wing spars of early production A380 aircraft. We have identified the issue and designed an inspection and repair scheme." an Airbus spokesman said.

The repairs, which must be carried out within 15 years of the initial wing box assembly, can be carried out during scheduled heavy maintenance visits, he added.

EASA in its directive said the condition, if not detected and corrected, could reduce the structural integrity of the wing.

Emirates, the world's largest A380 operator, has started checks on nine of its superjumbos and "so far, there has been nothing untoward in the findings," a spokeswoman said.

The Dubai-based carrier has 111 A380s in its fleet.

Singapore Airlines is to inspect four of its A380s, while Abu Dhabi's Etihad Airways said its A380s were newer models and not affected.

In 2012, Airbus was forced to carry out A380 inspections and devise a costly repair program after cracks were found on part of the wings, the world's largest for a passenger plane.

(Excerpt) Read more at money.usnews.com ...

“The Dubai-based carrier has 111 A380s in its fleet.”

Dang! Moving 500 bodies per trip? That’s a lot of folks moving around by air.

Some duct tape will fix this.

Riiiiight. And since the wing spar isn't necessary, why put it there in the first place?

IIRC,the oldest A380s are about 10 years old. Cracks in the wings? Sounds like Boeing isn’t the *only* one with problems.

...

This is all typical for the aircraft industry.

It shows how well the planes are inspected and maintained.

We don need no stinkin' wings!

An airliner sitting and baking at 110 degrees on a tarmac, then suddenly climbing to 30,000 feet with the outside temperature of -35 degrees puts an inordinate strain on any metal surface. One would assume and hope that the aeronautical engineers who design these aircraft did well in their material science courses and that these cracks are indeed superficial and no danger to the structural integrity of the aircraft. Yet given the computer engineering flubs at Boeing, confidence has been a bit eroded lately.

The wing design was a big engineering problem when the 380’s were built. My concern would be that Airbus provides some short cut fix to “resolve the problem”. Can’t see them changing out the main structural member.

In the middle east, that tarmac may be closer to 150 degrees.

From my experiences with race cars, any part that is made of aluminum (which the wing spars almost certainly are) that flexes under load, will eventually crack. Once it starts to crack, it deteriorates very quickly until it suddenly fails catastrophically.

I sure hope they have a well-thought-out maintenance/repair schedule and adhere to it religiously.

Are the wings still made in the UK ?

Speed tape. I use it to do in-field patching of ULD’s that have tears, punctures, holes, etc. That stuff will slice your finger open.

One dirty little secret is that modern FEA (Finite Element Analysis, a technique to simulate stresses and strains on a part’s design) based designs of all modern artifacts from buildings to bridges to cars and aircraft, allows the engineers to satisfy the business needs of reducing the materials used in anything to a bare minimum.

Good for cost and weight savings.

In the olden days parts were over-designed, and quite robust.

A DC-3 was so ‘over-designed’ that the were able to demonstrate how strong the wings were by running a steam roller over a wing without damaging it!

As a result, DC-3 (and the C-47 cousins) have survived amazing levels of abuse. From flying over The Hump, to the Berlin airlift where one plane had been given twice the maximum design load of coal by mistake.

Without FEA, classic designs were made from knowing what had failed, and designing the parts twice as strong and then adding a safety margin!

Modern designs have a certain elegance, and are more economical to purchase and operate, but are run much closer, but still not too close (mostly...) to their limits.

Your mistake is assuming the component was engineered with no margin of safety.

Your mistake is assuming I don't know what I'm talking about.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.