This one is around 1,700 years old and is doing just fine. Its quite a sight if your ever in Rome.

Posted on 02/15/2007 1:49:01 AM PST by neverdem

Where can you go to see a cool example of nanotechnology? Well, just about everywhere. A new study reveals that plain old concrete, the most common human-made material on the planet, owes its properties to its nanoscale structure. Down the road, this new understanding could lead to novel forms of concrete that require less energy and CO2 to generate and might allow researchers to engineer its properties much as they have done with advanced steel alloys. Concrete isn't what comes to mind when most people think of nanomaterials. It's the oldest engineered construction material and was first used by the Romans. Today, some 2.5 billion tons of the stuff is made every year, but at considerable environmental cost. Concrete starts out as a combination of limestone, clay, and gypsum that is heated to 1500 degrees Celsius to form cement. When combined with water, cement glues particles of sand and gravel together to create concrete. Estimates indicate that the energy used to create concrete accounts for 5 to 10 percent of the world's CO2 emissions.

As concrete sets and begins to dry, it forms a network made up primarily of calcium-silicate-hydrate, or C-S-H. The organization of that network has long remained a bone of contention among materials experts, as concrete's structure has proven challenging to confirm with traditional tools, such as x-ray, electron, and neutron scattering. To gain better insight, Franz-Josef Ulm, a civil engineer at the Massachusetts Institute of Technology in Cambridge, and his postdoc Georgios Constantinides used a needlelike "nanoindentation" device to prod different types of hardened cement pastes--the part of concrete that holds everything together--from around the world. An atomic force microscope allowed them to see the nanostructure and judge the strength of each paste by measuring the effects of the needle. They found that each type of cement consisted of myriad 4-to-5-nanometer-wide C-S-H particles that were either randomly arranged or ordered like oranges on a store shelf. The combination of those nanostructures largely accounted for the material's strength and durability.

"It's a great paper," says Hamlin Jennings, a civil engineer at Northwestern University in Evanston, Illinois. Jennings adds that if researchers can learn to control the packing of C-S-H nanoparticles in concrete they might be able to engineer concrete like alloyed steel. Ulm says that the findings could also help researchers find novel starting materials that create the tightly packed nanostructures without vast energy inputs, thereby helping people tread a bit more lightly on the planet.

"stuffed into the trunk of a Toyota that was subsequently sent to a car crushing plant."

Wow, just as in Goldfinger, but Bond got away, as always.:))

From my experience, having watched literally thousands of foundations for cell towers be poured, I've come to the conclusion that they still haven't got the original formula figured out yet, at least not consistently. I've seen several dozen over the years that had to be abandoned because they never reached the proper break strength, and thus the tower could not be stacked.

"C-S-H particles that were either randomly arranged or ordered like oranges on a store shelf", sounds a bit like ICE-9 to me.

Fifty to one hundred years? I was in Ephesus and saw a concrete dome 2000 years old. Part of it is still standing.

I'm longing for the days when CO2 won't--bafflingly--be referred to as a pollutant any longer.

This is more ludicrous than the enviro's treatment of DDT!

You're absolutely right. I've been there--twice. I've also seen a very good documentary of it on the History Channel.

Your example is far better than mine and I should have remembered this.

Up this early every morning... Got to make the daily bread!!

Wake at 5, check Truline Forum, make the rounds to about 7-8 other forums and out the door at 0545 sharp. Got it down to a science babe!

Your post reminded me of the Talking Head's tune, (Nothing But) Flowers.

Civil engineers ping

Ahh, a FReeRepublic topic near and dear to my heart!

Lemme know if you want on the ping list.

Gotta have the HRWR! What a loabor (and laborer!) saver! Chuck an egg in the mixrt, 60 spins, good to go! Turn a 4 slump mix into an 8" slump, with NO negative effects on the strength. It just kicks a little faster.

Microsilica fume (GGBFS) is the best damn thing in concrete technology since water and lime! Really helps strength, and chloide attack resistance.

LOL!

I have few loves in my life, but put everything I have into them. Beer, politics, my daughters and construction. Not necessarily in that order.

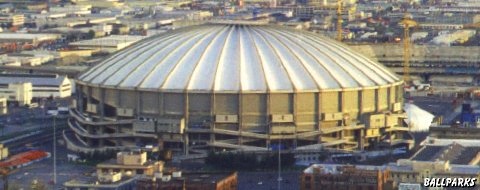

Us suckers in Washington State are still paying for this hunk -o-concrete and it aint even there no more!!!!!

8^(

LOL

Construction automation using inflatable structures to make concrete shells:

http://www.binisystems.com/ca.html

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.