Skip to comments.

Fabrication Trick Offers Fivefold Leap in Hard-Disk Capacity

MIT Technology Review ^

| November 16, 2012

| By Tom Simonite

Posted on 11/19/2012 7:38:08 AM PST by Red Badger

Current hard-drive designs are reaching their limit in data storage, but a new manufacturing technique could allow drive capacities to keep expanding.

A technique that enables the nanopatterned layers that store data in hard disk drives to assemble themselves has been improved to better suit mass production, and could enable disks that store five times as much data as the largest available today.

Using self-assembly instead of machines that print or etch out features has long been considered a potential solution to a looming barrier to expanding the capacity of hard-disk designs. Researchers at the University of Texas at Austin have now worked out a solution to a problem that made self-assembly incompatible with existing factories.

Hard disks store data on a spinning disk, written into a pattern of magnetized regions on a magnetic coating. For decades, gains in hard-drive capacity have come from packing those regions—and hence data—more densely. But now they can’t be positioned much closer together without magnetic interference endangering the reliability of data storage.

Covering a disk platter with physically separate dots of magnetic material instead of a continuous coat would allow much denser storage, since interference between the dots would be prevented by the gaps between them. But existing manufacturing methods can’t reliably make discrete islands spaced closer than about 30 nanometers apart, producing much the same data density as conventional hard-disk designs today.

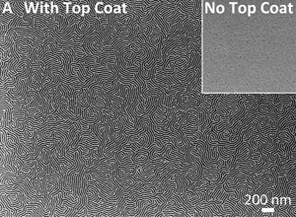

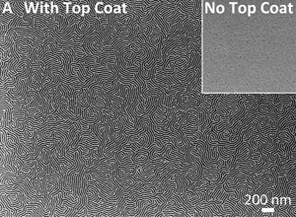

Grant Willson, a materials science professor at UT Austin, working with UT Austin chemistry professor Christopher Ellis, has found a way to create magnetic islands much more tightly packed than existing production tools are able to make. That new method uses a block of copolymers—long-chain molecules made of “blocks” of different polymers—that can assemble themselves into regular, and very small, repeating patterns. The patterns can be guided by choosing the right combination of polymers, and adding patterns to the surface they are applied to. Once formed, such a pattern can be used as a template to create dots of magnetic material on a hard-disk platter.

That approach has been held back by the challenge of getting long copolymer molecules to lay flat using a method compatible with existing factories. The UT Austin group announced last week that it had solved the problem by inventing a top-coat layer—also a polymer—that shuffles the copolymers into the right orientation.

“You just spin-coat a couple more layers than usual and heat the thing with the hot plate that's already in there,” says Willson. When the polymer top coat is applied, it is inactive, and bound up with ammonium ions. Heating drives off ammonia and switches the top-coat polymer into a new structure that interacts with the copolymer layer and encourages it to move into the desired orientation. The top coat is then washed off, leaving behind the copolymers and the structures they assembled into.

That process can be done in less than 30 seconds, faster than the current slowest step on a hard-disk platter manufacturing line, says Willson. So far, the group has shown that it can lay down patterns with details as fine as 10 nanometers. Willson estimates that this would allow hard drives to store data at five times their current density, approximately one terabit of information (1,024 gigabytes) per square inch.

HGST, a storage company owned by Western Digital, is investigating how the technique could be integrated into existing production lines. Willson says that his top coat will also need to be tuned for production by companies that specialize in semiconductor manufacturing.

James Watkins, director of the center for hierarchical manufacturing at the University of Massachusetts, Amherst, says that improvements are also needed to copolymers themselves before the self-assembly method can be used commercially. “One challenge is to achieve long-range order using copolymers without defects over large areas,” he says. With millions of data-storing dots on a disk’s platter, error rates must be very low to avoid significant numbers of them being positioned incorrectly.

TOPICS: Business/Economy; Culture/Society; Miscellaneous; Technical; Testing; US: Texas

KEYWORDS: computer; harddrive; it; memory

Navigation: use the links below to view more comments.

first 1-20, 21-40, 41-48 next last

Fine lines: Polymer molecules assembled themselves into the regular pattern of 10 nanometer-wide corridors in the larger of these two microscope images, thanks to the use of a new coating that helps the molecules align correctly. The smaller image shows that without the coating, the polymers don’t form organized structure

To: ShadowAce

2

posted on

11/19/2012 7:38:55 AM PST

by

Red Badger

(Lincoln freed the slaves. Obama just got them ALL back......................)

To: Red Badger

I’m surprised the industry is still so focused on spinning disk for storage, but considering the longevity and rewriteability of spinning disk vs. SSD, I suppose there’s room for improvement.

Could 10TiB - 15 TiB spinning disk be in our future?

3

posted on

11/19/2012 7:41:56 AM PST

by

rarestia

(It's time to water the Tree of Liberty.)

To: rarestia

At “one terabit of information (1,024 gigabytes) per square inch” they will be in your iPod.......

4

posted on

11/19/2012 7:45:37 AM PST

by

Red Badger

(Lincoln freed the slaves. Obama just got them ALL back......................)

To: rdb3; Calvinist_Dark_Lord; Salo; JosephW; Only1choice____Freedom; amigatec; stylin_geek; ...

5

posted on

11/19/2012 7:46:30 AM PST

by

ShadowAce

(Linux -- The Ultimate Windows Service Pack)

To: Red Badger

That is a heck of a lot of data capacity.

6

posted on

11/19/2012 7:48:38 AM PST

by

Army Air Corps

(Four Fried Chickens and a Coke)

To: Red Badger

Right !! This is the story of my life.... Just when my first 1TB drive is making it’s way from Tiger Direct to my house in the back of a UPS truck...sigh

7

posted on

11/19/2012 7:52:15 AM PST

by

Robe

(Rome did not create a great empire by talking, they did it by killing all those who opposed them)

To: Army Air Corps

That depends on how many pr0n videos you want to store........

8

posted on

11/19/2012 8:03:38 AM PST

by

Red Badger

(Lincoln freed the slaves. Obama just got them ALL back......................)

To: Robe

My first HDD was a 40MB Seagate. I paid over $300, mail order. I wondered how in heck I could EVER fill such a thing..........

9

posted on

11/19/2012 8:05:22 AM PST

by

Red Badger

(Lincoln freed the slaves. Obama just got them ALL back......................)

To: Red Badger

It should be enough capacity for at least one Jerry Garcia guitar solo.

10

posted on

11/19/2012 8:17:34 AM PST

by

Army Air Corps

(Four Fried Chickens and a Coke)

To: Red Badger

“My first HDD was a 40MB Seagate”

First one I ever bought was for our IBM AT (bigger brother to the PC). A huge metal can that held an astounding 5 megs, and only cost $1800+. Of course at the time, money wasn’t a concern because after all, nobody could ever fill up 5 megs. And compared to those big 8” floppies that only held 180k, we were now in the big leagues!

To: Red Badger

So, do they actually mean “5 FOLD” (32 times),

or do they mean “5 times”?

12

posted on

11/19/2012 8:21:04 AM PST

by

MrB

(The difference between a Humanist and a Satanist - the latter admits whom he's working for)

To: Red Badger

My first HDD was a 40MB Seagate. I paid over $300I have a file drawer full of those,I'll let 'em go cheap (8^)

13

posted on

11/19/2012 8:31:19 AM PST

by

Robe

(Rome did not create a great empire by talking, they did it by killing all those who opposed them)

To: Robe

I have a file drawer full of those,I'll let 'em go cheap (8^)

Before you clearance them, do note that some circuit boards of that vintage used real gold (especially on mother boards). At the very least the old 5 1/4" spinners tend to have REALLY COOL magnets inside.

14

posted on

11/19/2012 8:44:08 AM PST

by

Dr. Sivana

(There is no salvation in politics.)

To: Red Badger

I wish they would just let it die and force the move to solid state so the price would drop to reasonable levels. Problem with mechanical, multi-TB drives is that you need to use some sort of RAID method and a second backup due to the possible loss of huge amounts of data when even a single unit fails. It’s not like the old days, the failure rate on this garbage is high... I’d say 30% after 2 yrs of service. It’s gotten so bad, I mirror all my work on hot-pluggable docks and rotate them in and out of the safe deposit box.

15

posted on

11/19/2012 8:44:34 AM PST

by

FunkyZero

(... I've got a Grand Piano to prop up my mortal remains)

16

posted on

11/19/2012 8:54:56 AM PST

by

RedMDer

(May we always be happy and may our enemies always know it. - Sarah Palin, 10-18-2010)

To: MrB

17

posted on

11/19/2012 8:58:00 AM PST

by

Red Badger

(Lincoln freed the slaves. Obama just got them ALL back......................)

To: Red Badger

My first HDD was a 40MB SeagateMine was great until I loaded Windows 3.0

18

posted on

11/19/2012 8:59:12 AM PST

by

frithguild

(You can call me Snippy the Anti-Freeper)

To: frithguild

Mine was great until I loaded Windows 3.0

Mine was great until I loaded Windows 3.1

Mine was great until I loaded Windows 95

Mine was great until I loaded Windows 98

Mine was great until I loaded Windows 98SE

Mine was great until I loaded Windows ME

Mine was great until I loaded Windows NT

Mine was great until I loaded Windows 2000

Mine was great until I loaded Windows XP

Mine was great until I loaded Windows Vista

Mine was great until I loaded Windows..........

19

posted on

11/19/2012 9:04:54 AM PST

by

Red Badger

(Lincoln freed the slaves. Obama just got them ALL back......................)

To: Red Badger

iDevices won’t use platter disks of any form due to weight, shock, and power issues.

These are more likely to be used in large data centers where SSD is impractical and RAID arrays are par for the course to handle failed drives.

20

posted on

11/19/2012 9:05:53 AM PST

by

kevkrom

(If a wise man has an argument with a foolish man, the fool only rages or laughs...)

Navigation: use the links below to view more comments.

first 1-20, 21-40, 41-48 next last

Disclaimer:

Opinions posted on Free Republic are those of the individual

posters and do not necessarily represent the opinion of Free Republic or its

management. All materials posted herein are protected by copyright law and the

exemption for fair use of copyrighted works.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson