I don't know if this gross negligence stems from cost cutting measures in quality control, using inferior materials, or hiring less than qualified foreign engineers, but this is really scary.

1 posted on

03/04/2024 10:56:46 AM PST by

EinNYC

To: EinNYC

DEI = DIE......................

2 posted on

03/04/2024 11:01:26 AM PST by

Red Badger

(Homeless veterans camp in the streets while illegals are put up in 5 Star hotels....................)

To: EinNYC

The Max was designed with disproportionate input from bean counters, with predictable results.

To: EinNYC

Refer to the boeing doc on Netflix. They did this to themselves and deserve what is happening. Its too bad it takes people losing their lives to bring about change.

To: EinNYC

If there is an incident, you could get $1,500 from the airline. The tricky part is to survive it.

5 posted on

03/04/2024 11:07:18 AM PST by

Tai_Chung

To: EinNYC

[Boeing 737 Max

He got up and walked off.]

I don’t blame him. I don’t want to fly on an A/C that had to have software correct for the fact that the center of gravity was messed up from installing engines that are too large for the plane and had to be moved forward.

Plus the other problems.

6 posted on

03/04/2024 11:07:27 AM PST by

SaveFerris

(Luke 17:28 ... as it was in the Days of Lot; They did Eat, They Drank, They Bought, They Sold ......)

To: EinNYC

Would someone ping me to the posts from the Boeing social media team so I don’t have to read through the whole thread this evening?

Thanks.

7 posted on

03/04/2024 11:11:50 AM PST by

PAR35

To: EinNYC

“If it’s Boeing, ‘I ain’t going’ ... “It doesn’t matter which model, I don’t want to fly them.” “

Good luck with that ... 43% of the commercial planes flying in the U.S. are Boeing.

To: EinNYC

10 posted on

03/04/2024 11:19:03 AM PST by

Grampa Dave

(“Surrender means wisely accommodating to what is beyond our control.” — Sylvia Boorstein.)

To: EinNYC

Sounds like the gobs putting the planes together are lazy

11 posted on

03/04/2024 11:22:55 AM PST by

Nifster

( I see puppy dogs in the clouds )

To: EinNYC

There was a marked decrease in the quality of Boeing products when the head office was moved from Seattle to Chicago.

This is just a further outgrowth of that corporate decision.

13 posted on

03/04/2024 11:31:59 AM PST by

Don W

(When blacks riot, neighborhoods and cities burn. When whites riot, nations and continents burn)

To: EinNYC

The move comes as critics have repeatedly said that the aircraft manufacturer is prioritizing profits over safety. When the Alaskan Airlines thing happened with the door, the story going around on conservative websites was that Boeing had subcontracted a DEI company that manufactured the doors. I scanned the article very quickly and did not see that mentioned anywhere.

To: EinNYC

None of those things.

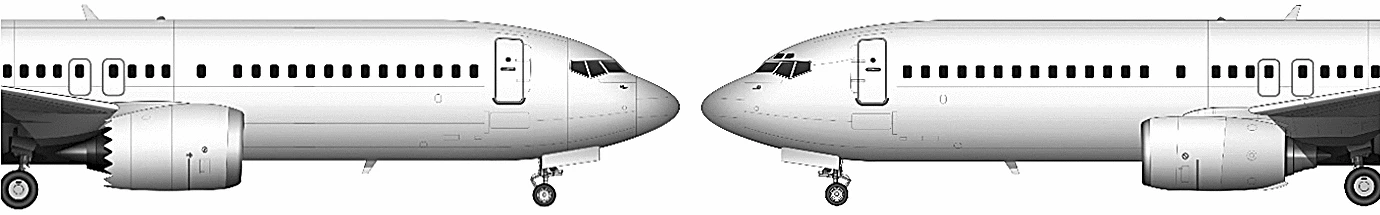

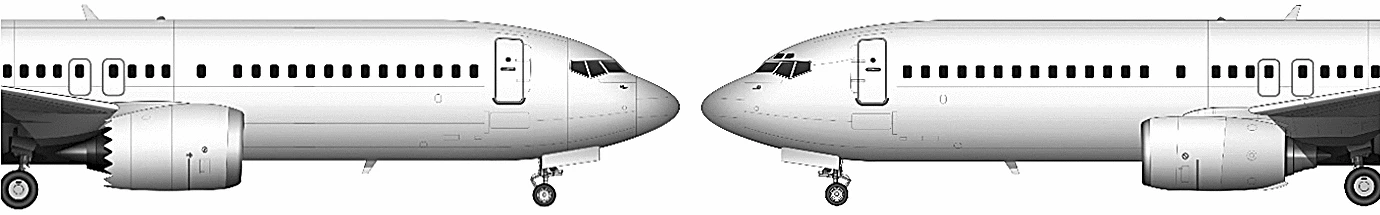

To keep up with its main Airbus competitor (on fuel economy), Boeing elected in 2011 to modify the latest generation of the 737 family, the 737NG, rather than design an entirely new aircraft. The 737 MAX was an updated version of the 737 workhorse that first began flying in the 1960s. This raised a significant engineering challenge: how to mount the larger, more fuel-efficient engines (similar to those employed on the Airbus A320neo) on the existing 737. The original 737 family used low-bypass engines and was built closer to the ground than the Airbus A320.

To provide appropriate ground clearance, <>the larger, more efficient engines had to be mounted higher and farther forward on the wings than previous models of the 737. This significantly changed the aerodynamics of the aircraft and created the possibility of a nose-up stall under certain flight conditions.

(The Boeing 737 MAX: Lessons for Engineering Ethics, 10 July 2020.)

R. John Hansman, a professor of aeronautics at the Massachusetts Institute of Technology:

...in high angles of attack the Nacelles -- which are the tube shaped structures around the fans -- create aerodynamic lift. Because the engines are further forward, the lift tends to push the nose up -- causing the angle of attack to increase further. This reinforces itself and results in a pitch-up tendency which if not corrected can result in a stall. This is called an unstable or divergent condition. It should be noted that many high performance aircraft have this tendency but it is not acceptable in transport category aircraft where there is a requirement that the aircraft is stable and returns to a steady condition if no forces are applied to the controls.

Boeing's fundamental design mistake was with the size and placement of the 737 MAX engine because of the potential for aerodynamic instability caused by its engine. This is an appropriate design for high-performance aircraft, but inappropriate for passenger aircraft.

To counter this inherent design instability, Boeing installed the MCAS software that pushed the nose down if it detected an unstable angle of attack...but did NOT tell any airline or pilot about the system.

After the crashes, Boeing proposed to modify the MCAS to require that both AOA sensors deliver similar readings -- they must be within 5.5 degrees -- before triggering the MCAS to tip down the nose. Boeing's fix would also limit how sharply the MCAS can tip the nose down -- to no more than flight crew can counteract by pulling back on the control column in the cockpit. The fix would only allow the MCAS to tip down the nose once, rather than repeatedly -- as the current version does -- thus making it easier for pilots to recover.

Note that the MAX had only TWO Angle of Attack sensors rather than three, so the system was inherently susceptible to AOA sensor failure. If the system gets two different readings from the two AOA sensors, which should it use?

In the October 29, 2018, Lion Air flight JT610 crash, the flight data recorder showed that MCAS forced the nose of the aircraft down TWENTY SIX times in 10 minutes. The pilots fought the MCAS all the way down.

Bottom line...Boeing management thought that they could compete with Airbus by installing the large high-efficiency, low fuel consumption engines on the 737 in an inherently unstable location higher up and more forward. They decided to do that rather than design a completely new aircraft. They decided to compensate for the inherent instability through software that was not disclosed or trained to airlines and pilots.

It was executive leadership failure.

15 posted on

03/04/2024 11:41:16 AM PST by

ProtectOurFreedom

(“Occupy your mind with good thoughts or your enemy will fill them with bad ones.” ~ Thomas More)

To: EinNYC

Boeing has been suckling off the gubmint teat for decades. Its systemic in the most valid use of the word.

16 posted on

03/04/2024 11:43:56 AM PST by

Delta 21

(If anyone is treasonous, it is those who call me such.)

To: EinNYC

I think I see the problem with the MAX program: Boeing hired idiots like this to work on the program.

He couldn’t tell it was a 737 MAX from the window before boarding? I don’t even work for Boeing or in the aviation industry and can spot a MAX from the window. The engine chevrons (and nacelle size/shape), the winglets and the APU area are quite different than the 737 NG.

I think if I was that terrified to board one these planes, I’d at least learn what they look like and look out the window before boarding it instead of waiting to view the safety card after being seated.

I wonder how many incorrect cars he’s sat in when ordering an Uber. Why check the license plate? Just get into the car.

17 posted on

03/04/2024 11:50:56 AM PST by

OA5599

To: EinNYC

The 737 MAX software was written by Indians.

18 posted on

03/04/2024 11:56:04 AM PST by

jroehl

(And how we burned in the camps later - Aleksandr Solzhenitsyn - The Gulag Archipelago)

To: EinNYC

When pilots start refusing to take the wheel of a “Max” I’ll get worried.

To: EinNYC

22 posted on

03/04/2024 2:37:32 PM PST by

logi_cal869

(-cynicus the "concern troll" a/o 10/03/2018 /!i!! &@$%&*(@ -)

To: EinNYC

Boeing needs to come up with a replacement for 737 Max line. And then replace all 737 Max 8 and 9 planes.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson