Skip to comments.

My invention

djf

Posted on 09/13/2008 10:24:53 PM PDT by djf

A while back in February of this year I posted a thread asking if there were any FReepers with patents.

I had two purposes: to find out info about the getting-a-patent process, as well as hopefully find someone with a somewhat mutual interest who might join in.

Alot of FReepers provided good info about the getting part, and I researched the law, it is truly daunting.

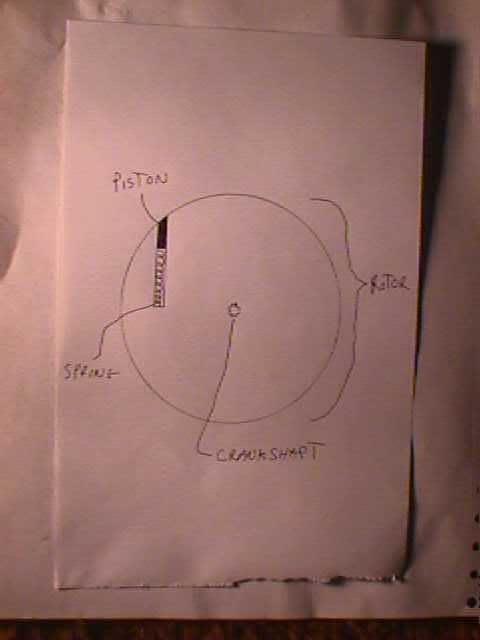

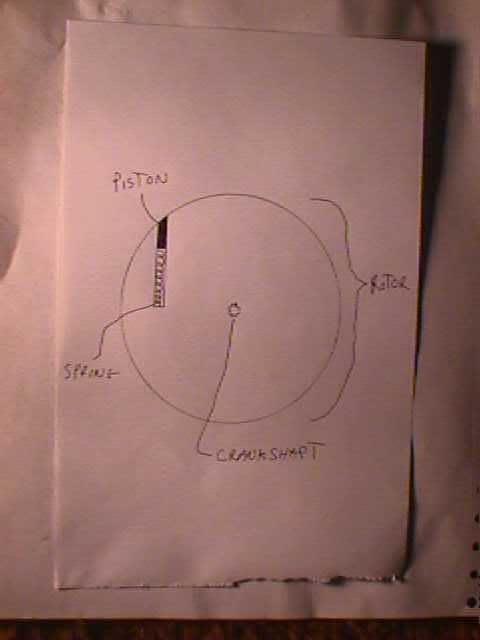

So I have decided to show here a quick sketch of my invention. I have asked a number of folks (all who have signed NDA's) and everyone agrees that it is a very, very interesting concept, and none of them had ever seen it before.

For years I was interested in designs for reciprocating engines. One night I fell asleep thinking about it and the next morning I knew exactly what it was.

I have a number of associates who have detailed drawings of my idea and various configurations. It is extremely versatile, and slight changes to the design can make it suitable for a huge number of applications.

It is a rotor that can go in an engine.

The design is very simple, a hockey puck shaped rotor. The crankshaft comes straight out the center. But it is different from a Wankel type system, as it has a piston mounted in the rotor. As the piston is compressed against the spring, the rotor turns, and the piston goes back to it's rest position.

Anyways, I put together about 15 variations of the design, with multiple pistons, etc. The draft documents are in safes spread out over a couple states.

I retain any and all rights to this idea. I will sell the idea to a bidder for an appropriate amount and a nominal fee of ten US dollars per unit produced.

As of now, there are no prototypes. A huge advantage of the design is it can be powered by just about anything. Internal combustion, compressed air, magnetism, actual mechanical compression of the piston.

So that's it! I think it's an important find. If it's been done already, guess I gotta cry in my beer. But when people I know who have been working with engines and motors for thirty plus years tell me it's something worth pursuing, then I gotta do something about it.

TOPICS: Miscellaneous; Science; Society

KEYWORDS:

Navigation: use the links below to view more comments.

first previous 1-20, 21-40, 41-60, 61-66 last

To: djf

Thanks for the more detailed drawing. I understand the concept now.

Several comments follow which you will not like. I truly hate to be discouraging to any entrepreneur, but I feel you need a serious dose of reality.

First a bit of my background so you know where I'm coming from. I'm a regional Engineer with a large power generation company. I specialize in rotating machinery vibration analysis, transformer oil analysis, machinery lube oil analysis, infrared Thermography, motor circuit condition analysis and motor current signature analysis. I have an extensive background in industrial combustion turbines and all types of electric motors.

Enough of the resume, on to the comments.

Forget the electrical input idea. What you will get is a horribly inefficient electric motor with far more complexity that any existing type of electric motor.

Why? For one reason amony many, when you push the piston down the spring will compress and push on the rotor imparting motion. The spring will absorb energy and convert it to heat for no reason what so ever. Why have a piston at all? Just have a magnet mounted in the rotor? But then you'd be pretty close to a conventional electric motor.

Well, close in some ways, but overall that's far to complex and inefficient a way to turn a rotor, especial considering the sheer simplicity of a AC induction motor with ONE moving part and no brushes or other friction components save the bearings. I could go deeper into this, but just trust me here. Electric input for this design is a bad idea.

So that brings us to the combustion or compressed gas method.

Several things to point out here.

How are you going to compress the air fuel mixture? The combustion chamber will have to contain the mixture, and it will ignite when the piston is directly underneath? How will the air fuel get into the chamber? There is no down stroke of the piston while it’s under the chamber to draw it in, so it will have to be pushed in and compressed by something else. What? Another rotor dedicated just to feeding this one?

Is the top of the piston angled like in the drawing? If so, a large portion the energy from combustion will be directed at pushing the piston into the side wall due to the angle of the piston top. If the piston top is flat, that will dramatically increase the area of the pre ignition cylinder head space, requiring a far more compressed mixture of air/fuel to give it any power at all. And how will you get any power given the constraints on available piston surface area?

The fact that it always rotates in one direction will minimize harmonics. In fact, the very act of the object spinning when a piston is compressed is itself a sort of harmonic balancer.

This statement indicates that you do not understand what harmonics are. I’m sorry to be blunt, and I’m not trying to be rude, but that’s just a fact.

By the way, I don’t think harmonics would be an issue. It could be but if it is, it’s easy to fix. I do it all the time. But the fact that you address an issue that will not likely be a problem with an inaccurate statement regarding the subject indicates that you don’t understand what forces are at work on rotating machinery.

How will you maintain a gas tight seal between the rotor and the casing wall especially during thermal expansion? Also, regarding your comments on thermal expansion:

Now, I've thought about this idea for a long time, and consider questions like "What do you do with the exhaust" and "What about thermal expansion" to be somewhat minor design and materials questions. I am not an expert in large tooling machines or material properties, although I know a few who are, and all of them say this is very workable.

“somewhat minor design and materials questions”. Another statement that tells me you’re in way over you head here, regardless of what your friends say.

You talk about simplicity. Try this. Remove the three pistons with their energy wasting springs, replace them with continuous set of chambers around the circumference of the rotor, and instead of a combustion impulse occurring only three times per rotation, have a continuous combustion or compressed gas fed to the rotor.

Now you’ve got something.

It’s called a turbine, an impulse turbine to be exact. Something that has been around for eons, and is far more efficient and powerful that what you have here. And an impulse turbine is the least efficient type of turbine to boot. But talk about simple!

But if you do manage to sell this idea to anyone, I will declare you a genius of Einstein like magnitudes. A marketing genius that is.

Seriously, before you spend any money on this, take you idea to a mechanical engineer who is NOT a friend. He’ll save you lots of money, time and possibly embarrassment.

Once again, I’m sorry for such a negative response, but I think you need it.

61

posted on

09/14/2008 2:17:50 PM PDT

by

Jotmo

(I Had a Bad Experience With the CIA and Now I'm Gonna Show You My Feminine Side - Swirling Eddies)

To: djf

I really do hate to be such a turd in the punch bowl, as it were, but I don’t want to see anyone throw money away on useless endeavors either. There are plenty of people that will string you along and tell you you’ve got a real winner idea, and take as much of your money as they can manage in the process.

Building a prototype will require a good machine shop, some casting, and even perhaps some rapid prototyping machines. They will gladly take your money and build anything you want, all the while keeping you as pumped up about it as long as you have any money left.

It may sound odd, but actually, my feelings on the matter are quite the opposite of my tone thus far. I really wish your idea was as useful and revolutionary as you want it to be. It’s just that cold hard physics and mechanical engineering stands in the way.

But if I may, I’d like to add an addendum to all my previous posts. A counter, of sorts, to all the negativity.

Don’t give up! Keep thinking new ideas and designing new things. If you try long enough, and keep at it, I have no doubt you come up with something new and remarkable to market, that will benefit many people and make you obscenely rich in the process. This one is just not it.

But don’t ever give up on you dreams, it’s people like you who are willing to take risks and dare to try new things that makes our country great.

62

posted on

09/14/2008 8:53:03 PM PDT

by

Jotmo

(I Had a Bad Experience With the CIA and Now I'm Gonna Show You My Feminine Side - Swirling Eddies)

To: Jotmo

Well, believe it or not, I appreciate all comments, positive or negative.

As I said early on part of this is sort of an “outreach”. I have alot of tools and routinely take things apart to fix them, or use my Dremel to manufacture replacement parts for things, or work on cars or motors.

But I simply do not have the extensive machine shop things. Nor do I know about the methods, the benefits or drawbacks of various manufacturing techniques.

But my thought is it is either:

A new idea, AND is feasible, AND it has applications or

it’s not new, it is not feasible, or it has no applications.

But without having even a simple prototype, I’m sorta stuck, and will end up wondering forever.

Just seems to me that the reversal of direction of the pistons in a standard combustion engine isn’t as “smart” an idea as this.

A very simple, passive rotor.

63

posted on

09/14/2008 10:15:02 PM PDT

by

djf

(This ain't no party, this ain't no disco, this ain't no fooling around...)

To: ShadowAce; Ernest_at_the_Beach

|

"First we'll get everyone to maintain proper tire inflation, THEN we'll try your idea." |

64

posted on

09/14/2008 10:59:19 PM PDT

by

SunkenCiv

(https://secure.freerepublic.com/donate/_______Profile hasn't been updated since Friday, May 30, 2008)

To: Jotmo

I think I've had an experience similar to the inventor in that I think of a more complicated way to do something and believe that it is fundamentally different.

As you say one remove the springs and pistons, inject high pressure gas and exhaust it at some point to make the rotor spin but then it becomes a valving and sealing problem.

Even the lobed rotary engines wrestled with sealing the combustion chamber.

Better you be blunt than encourage failure.

65

posted on

09/14/2008 11:54:15 PM PDT

by

count-your-change

(you don't have to be brilliant, not being stupid is enough.)

To: djf

Just seems to me that the reversal of direction of the pistons in a standard combustion engine isn’t as “smart” an idea as this. You're correct in that it is an efficiency killer in some ways.

That is why we have turbines. All the the energy is applied in a uniform direction with the effect of turning the rotor. Very efficient when at speed, but with the disadvantage of having no torque at low RPM.

Turbines must run a fairly high speeds which makes them inefficient for cars and such which require a wide range of RPM to function. Yes you can gear it down, but having a turbine spinning at such high speeds all the time, regardless of the power needs of the car is a huge fuel waster. You can drop the turbine RPM while the car is stopped, but then to move again you must wait for the turbine to spin up again due to the lack of torque at low RPM. There actually was a turbine powered car. It didn't perform well for the above mentioned reasons.

Also the exhaust from a turbine is extremely hot, up-wards of 1500 degrees or so. I remember reading an article where Jay Leno was talking about riding a turbine powered motorcycle. He said that if you stopped under a tree, the exhaust, which was directed upward, would set the tree on fire.

So while you're correct in some respects, you have to realize that pure efficiency of the turning rotor is not the entire picture. You must view the efficiency as it is applied to the situation. An efficient way to turn a rotor means nothing if I have now power available at the speeds needed to actually use it. There's a reason cars don't use turbines, and big airplanes don't use piston engines.

What you tried to do is take something from one technology (reciprocating piston) and apply it to a technology (turbine) where it is simply useless. The reversal of the "pistons" in a rotor which is already spinning just has no purpose.

And I don't expect you to just take my word for it either. Like I said, do some more research and take it to an engineer if you have any lingering doubts about my opinion.

Once again, let me encourage you to not give up on you desires to invent something new. But from your comments I can see that you need some education and experience to put your enthusiasm, drive and creative abilities to good use.

I truly believe you are capable of doing something great, and I hope you do. Don't let failures, or even, dare I say, negative people get in your way.

66

posted on

09/15/2008 6:01:34 AM PDT

by

Jotmo

(I Had a Bad Experience With the CIA and Now I'm Gonna Show You My Feminine Side - Swirling Eddies)

Navigation: use the links below to view more comments.

first previous 1-20, 21-40, 41-60, 61-66 last

Disclaimer:

Opinions posted on Free Republic are those of the individual

posters and do not necessarily represent the opinion of Free Republic or its

management. All materials posted herein are protected by copyright law and the

exemption for fair use of copyrighted works.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson