Patterned media nanoholes

Posted on 04/20/2008 9:13:39 AM PDT by Ernest_at_the_Beach

Hard drives could experience a massive increase in capacity next year now that a "major" HDD maker has placed an order for equipment to mass-produce 'patterned media' drives.

Earlier this week, Malmö, Sweden-based fabrication-equipment maker Obducat announced it had reached an agreement with "a major player in th HDD industry" to supply the unnamed company with up to SKR66m ($11.13m) worth of lithography hardware.

Obducat will provide the mystery vendor with a "production-ready" Sindre lithography machine, used to create the high data-density surfaces used by the new drive technology. More equipment orders may follow, the Swedish firm said.

Fujitsu is a possible candidate for the HDD maker behind the Obducat deal - it has worked on patterned media technology since 2005. Canon was working on the technology in the early years of the decade and continues to do so, but it's not a major hard drive maker.

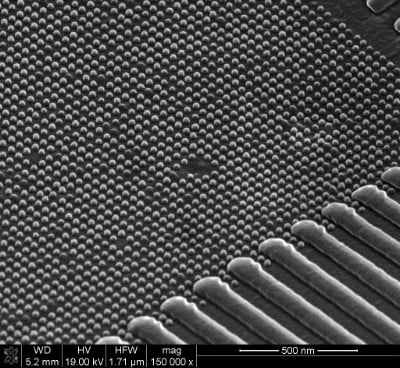

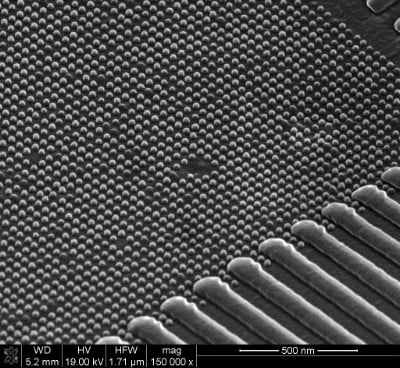

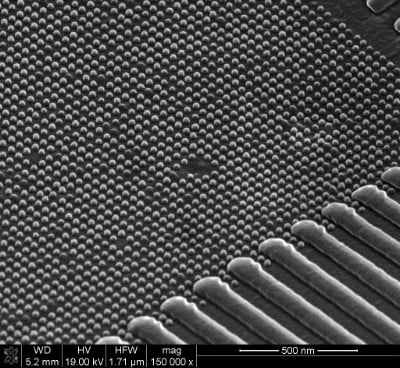

The technique involves establishing microscopic 'nanoholes' within a sheet of aluminium oxide. The holes form a pattern, hence the name.

Patterned media nanoholes

Each hole is filled with a magnetic material, each holding a single data bit. The surrounding oxide insulates each hole from its neighbours, preventing data corruption.

The holes are so small, they can only be created using the lithography techniques employed to make microprocessors and other chips.

Obducat claims its Sindre systems have been used to create holes as small at 17nm in diameter - not far short of the 13nm that Fujitsu last year reckoned was required to yield an areal density of 1TB per square inch.

That compares with the 65GB per square inch record claimed by Western Digital back in October 2007 - and even that's higher than the 25GB per square inch density of typical HDDs.

Obducat said its customer will take delivery of the first Sindre litho systems in "the first half of 2009". The machines are designed to work on 4, 6 or 8in wafers and, Obducat claims, can churn out discs at a rate of up to 30 per hour.

Yields are another matter, of course, but the company has the best part of a year to work on that, with further tweaking once its customer gets the systems in place. Another major challenge is getting the nanoholes into the precise order needed for read/write heads to access their contents efficiently.

Thanks to reader Patrik Stockselius for the tip ![]()

Fujitsu hails HDD capacity breakthrough

*******************************EXCERPT**********************

By Tony Smith [More by this author]

Fujitsu has developed a technique it claims will allow the company to produce hard drives with an areal data density of 1Tb per square inch - almost seven times the density of today's latest perpendicular-recording hard drives.

Fujitsu's approach is based on what the company calls 'patterned media'. Essentially, the technique uses anodised aluminium to create a pattern of holes, each holding a portion of magnetic material used to store a single bit of data. The aluminium-oxide surrounding these so-called 'nanoholes' helps magnetically insulate each bit from all the others, preventing one from affecting another, which might lead to data corruption.

fyi

WD claims highest hard drive density crown

*********************************EXCERPT*************************

By Tony Smith [More by this author]

Western Digital has claimed to have created the world's highest density hard drive platter, a unit that packs in 520Gb per inch squared - more than double the highest density products on the market today.

They typically offer an data density of 200Gbpi² - just not enough to yield the 640GB-per-platter storage capacity needed to yield 3.5in hard drive capacities of 3TB, WD said.

Interestingly, WD said it had demonstrated the higher areal density using a Tunneling Magneto-Resistive (TMR) read/write head of the kind Hitachi this week said wouldn't be up to the tasks of reading data off a 500Gbpi² platter. Hitachi made that claim when it announced its putative successor head technology, Current Perpendicular-to-the-Plane Giant Magneto-Resistive (CPP-GMR).

For its part, WD said its latest development showed "the extendibility of TMR head technology generations into the future".

WD said it expects 3TB drives to go on sale in 2010, but curiously it based that forecast on "on the industry's current density growth rate of more than 40 per cent per year" rather than when it expects to be able to bring its 520Gbpi² platters to market. Will the two coincide? Only a few years to wait to find out...

In January this year, Fujitsu said it had developed the technique that will allow it to create drives with an areal density of 1Tbpi². It too reckons it will be able to offer HDDs of that density in 2010. ![]()

Sale ends Tuesday...

In terms of such technologies . . . I’m just an ignorant layman silly rabbit shrink . . .

But I’ve long wondered . . . .

Why wouldn’t it be possible . . . to construct read/write heads that were . . . say on 4 or more arms and slightly changed in alignment to deal with the spiral data or change the spiral data to nonspiral . . . Seems like such could be faster and remove the issue of crashing flying heads if the read/write were embedded in a solid disc slightly above the data disc.

or

even have solid state read/write sensors above the data disc that populated bit points equal to the bit points of the data disc . . . or maybe a read disc below and write disc above??

I’m sure there must be vast technical reasons such is undoable but I’ve long been curious so thought I’d ask this talented group.

But now we have flash drives advancing . . . and holographic crystal storage looming . . . ?? Right?

I know very little,..but you know that the heads actually fly over the surface...which means ....to me...that aerodynamic design issues are involved...

ping

Right. That’s what I’m puzzled . . . about . . . why wouldn’t say a solid disc above and/or below solve the aerodynamic issues?

Hitachi halves hard drive head size

******************************EXCERPT***************************

By Tony Smith [More by this author]

Hitachi has developed a hard drive read/write head that's half the size of the units found in today's top-of-the-line HDDs - a crucial step, it claimed, to delivering a 4TB desktop drive, albeit not until 2009 at the earliest.

Hitachi's new head may be tiny - 30-50nm in size, one two-thousandth of the thickness of a human hair - but the technology it's based on is something of a mouthful: Current Perpendicular-to-the-Plane Giant Magneto-Resistive (CPP-GMR).

Of interest?

interesting. Thanks.

I'd like to have about 50TB so I would have a central location to store all of my VMs at work.

December 13, 2006 12:54 PM PST

Al Shugart—the man who founded Seagate Technology, convinced his pet dog to run for public office, and favored Hawaiian shirts over business suits—has died at age 76.

Hard drives could experience a massive increase in capacity next year now that a "major" HDD maker has placed an order for equipment to mass-produce 'patterned media' drives.

Earlier this week, Malmö, Sweden-based fabrication-equipment maker Obducat announced it had reached an agreement with "a major player in th HDD industry" to supply the unnamed company with up to SKR66m ($11.13m) worth of lithography hardware.

Obducat will provide the mystery vendor with a "production-ready" Sindre lithography machine, used to create the high data-density surfaces used by the new drive technology. More equipment orders may follow, the Swedish firm said.

Fujitsu is a possible candidate for the HDD maker behind the Obducat deal - it has worked on patterned media technology since 2005. Canon was working on the technology in the early years of the decade and continues to do so, but it's not a major hard drive maker.

The technique involves establishing microscopic 'nanoholes' within a sheet of aluminium oxide. The holes form a pattern, hence the name.

Patterned media nanoholes

Each hole is filled with a magnetic material, each holding a single data bit. The surrounding oxide insulates each hole from its neighbours, preventing data corruption.

The holes are so small, they can only be created using the lithography techniques employed to make microprocessors and other chips.

Obducat claims its Sindre systems have been used to create holes as small at 17nm in diameter - not far short of the 13nm that Fujitsu last year reckoned was required to yield an areal density of 1TB per square inch.

That compares with the 65GB per square inch record claimed by Western Digital back in October 2007 - and even that's higher than the 25GB per square inch density of typical HDDs.

Obducat said its customer will take delivery of the first Sindre litho systems in "the first half of 2009". The machines are designed to work on 4, 6 or 8in wafers and, Obducat claims, can churn out discs at a rate of up to 30 per hour.

Yields are another matter, of course, but the company has the best part of a year to work on that, with further tweaking once its customer gets the systems in place. Another major challenge is getting the nanoholes into the precise order needed for read/write heads to access their contents efficiently.

I submit that Al Shugart would have made a better President than any of the three bozos running this year.

Rest in Peace Al, may your boot sector sleep in serenity! :)

> Why wouldn’t it be possible . . . to construct read/write

> heads that were . . . say on 4 or more arms ...

When I asked that question of some R&D guys back in the

80s, the answer was that the unpredictable inertial

interaction (vibration) between the heads and the

platters made it impossible to compensate for.

Multiple heads on the same arm has been considered too,

and is apparently too heavy, for starters.

Head-per-track, of course, is what drum drives were.

No one misses them.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.