Skip to comments.

Windham Carbon Fiber AR-15

Am Shooting Journal ^

| 6/18/20

| N Gray

Posted on 06/18/2020 6:53:15 AM PDT by w1n1

Since the weight of an AR-15 rifle varies from manufacturer to manufacturer and model to model, it can sometimes be an undesirable element for women who shoot them. A fully accessorized AR-15 can weigh upwards of 10 or more pounds with a fully loaded, high-capacity magazine.

Since the weight of an AR-15 rifle varies from manufacturer to manufacturer and model to model, it can sometimes be an undesirable element for women who shoot them. A fully accessorized AR-15 can weigh upwards of 10 or more pounds with a fully loaded, high-capacity magazine.

This weight can cause the shooter to lean backwards to compensate, and in turn, makes these heavier guns un-enjoyable. If you’re physically fit and do strength training, weight has a reduced affect, but supporting a heavier rifle will eventually affect the shooter causing them to focus more on the weight and less on the target. If you can identify with this, please read on.

The second concern I commonly hear has to do with a heavy trigger pull. This can be just as much a concern as weight. Women, including my wife, have disparaged the heavy trigger pull of an AR-15 as well as some handguns, especially ones with double-action-only triggers. Many old military rifles including AR-15s have what is referred to as a "military trigger," and on average have an 8- to 10-pound pull.

The original reason for this was so that when the adrenaline was flowing, the shooter would not be able to pull the trigger easily, and experience an unintended discharge. A suggestion would be adding a Timney drop-in trigger. They are easy to install (they drop in using the existing pins) and you have several trigger-weight options to choose from.

Many years ago while walking the floor at SHOT Show, I met with the representative from Windham Weaponry. I told them my concerns about women having to deal with heavy ARs and how some companies are starting to employ polymers to reduce the weight of both the upper and lower receivers. Their rep walked me over to a display and handed me their Windham Weaponry Carbon Fiber "SRC." I couldn't help but notice the reduced weight of the rifle. I was impressed and knew this could serve as a great alternative to the heavier aluminum receivers. I had seen some polymer receivers around, but at the time didn’t know of anyone who effectively used it for both upper and lower receivers.

This SRC starts with a 16-inch, M4-style, chrome-lined barrel which has a 1-in-9-inch right-hand-twist rate that works well for stabilizing bullets from 55 to 75 grains. It finishes off with an an A2 flash suppressor. The gas block sports a MIL-STD-1913 Picatinny rail for mounting any front sight you choose, as well as has a standard bayonet lug and sling swivel. A word of caution: use a sight constructed of steel, as the gas block will heat up considerably and possibly melt other sights. The handguards have a double-layered heat shield to protect from the heat and are constructed of plastic. They are easily grasped and can be replaced with a quad rail hand guard. Read the rest of Windham Carbon SRC.

TOPICS: Hobbies; Outdoors

KEYWORDS: advertising; ar15; banglist; blogpimp; momsbasement; windham

1

posted on

06/18/2020 6:53:15 AM PDT

by

w1n1

To: w1n1

A fully accessorized AR-15 can weigh upwards of 10 or more poundsWell, $hit, stop putting on so much useless furniture. I build AR's (for myself) and average empty gun weight less than 5 pounds with optics. Thats without carbon fiber receivers. I dont mind carbon fiber on some components even though its expensive and not really necessary, but I want my receivers to last forever and forged or machined aluminum is my preference. Its the weight out on the front end that really matters anyway, not so much on the back end.

2

posted on

06/18/2020 6:59:36 AM PDT

by

Magnum44

(My comprehensive terrorism plan: Hunt them down and kill them.)

To: w1n1

Less weight, more felt recoil. Which would women prefer?

3

posted on

06/18/2020 7:06:22 AM PDT

by

DugwayDuke

(A Man Hears What He Wants to Hear and Disregards the Rest)

To: w1n1

The second concern I commonly hear has to do with a heavy trigger pull. My comment on this...The desired usage determines the desired trigger weight. If you are only going to shoot from a bench at paper targets for accuracy, get a light trigger. But then why waste a perfectly good AR to only bench shoot? If you are going to practice defensive shooting use a trigger close to mil spec weight, so as to reduce the chance of AD.

4

posted on

06/18/2020 7:06:40 AM PDT

by

Magnum44

(My comprehensive terrorism plan: Hunt them down and kill them.)

To: Magnum44

“Well, $hit, stop putting on so much useless furniture.”

Bingo. We see people with lasers, flashlights, and loads of other things hanging off their AR rifles. Ours our M4geries with red dot optics. That’s it. They’re about 7 pounds unloaded. The Mrs handles hers just fine.

L

5

posted on

06/18/2020 7:06:48 AM PDT

by

Lurker

(Peaceful coexistence with the Left is not possible. Stop pretending that it is.)

To: w1n1

If an AR-15 is too heavy, get an M-1 Carbine.

6

posted on

06/18/2020 7:08:06 AM PDT

by

Joe 6-pack

(Qui me amat, amat et canem meum.)

To: DugwayDuke

Not much recoil in an AR, least not in the standard .223, regardless of the weight. Buffer takes up most of the recoil. Not even a small lady should complain about what recoil remains.

7

posted on

06/18/2020 7:08:12 AM PDT

by

Magnum44

(My comprehensive terrorism plan: Hunt them down and kill them.)

To: w1n1

Carbon fiber 3D printing is coming down in price. I haven't seen a homemade lower made from it yet.

From the article: "The cooling and heat-dissipation properties of the carbon fiber are noticeably better than their aluminum counterparts, . . ."

Typical AMSJ writing. It's because the carbon fiber upper is acting as an insulator, not a heat dissipator.

To: DugwayDuke

LOL, felt recoil! With an AR? LOL

9

posted on

06/18/2020 7:35:00 AM PDT

by

MHGinTN

(A dispensation perspective is a powerful tool for discernment)

To: Magnum44

Marines somehow manage to shoot at 500 yards with iron sights with that terrible “heavy” trigger. Anyone who complains about the standard AR trigger doesn’t know how to run a trigger.

10

posted on

06/18/2020 8:18:56 AM PDT

by

DesertRhino

(Dog is man's best friend, and moslems hate dogs. Add that up. ....)

To: IndispensableDestiny

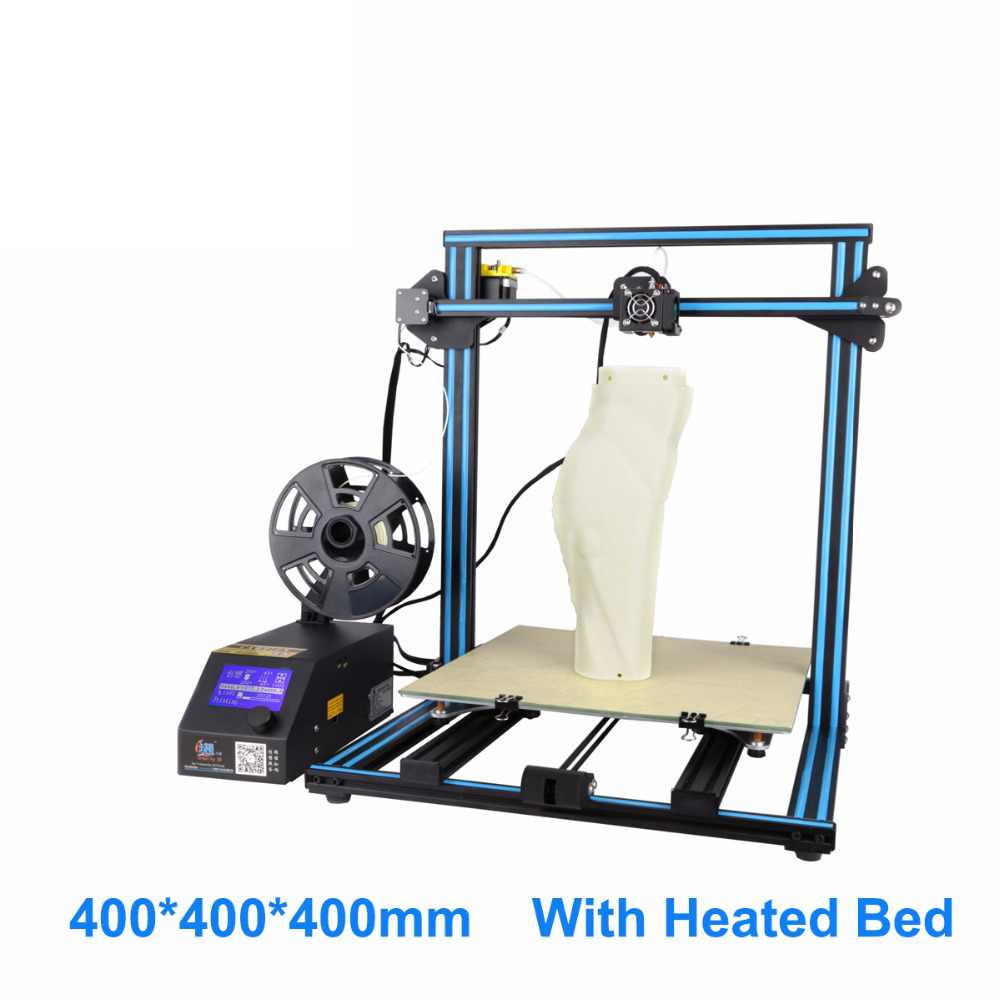

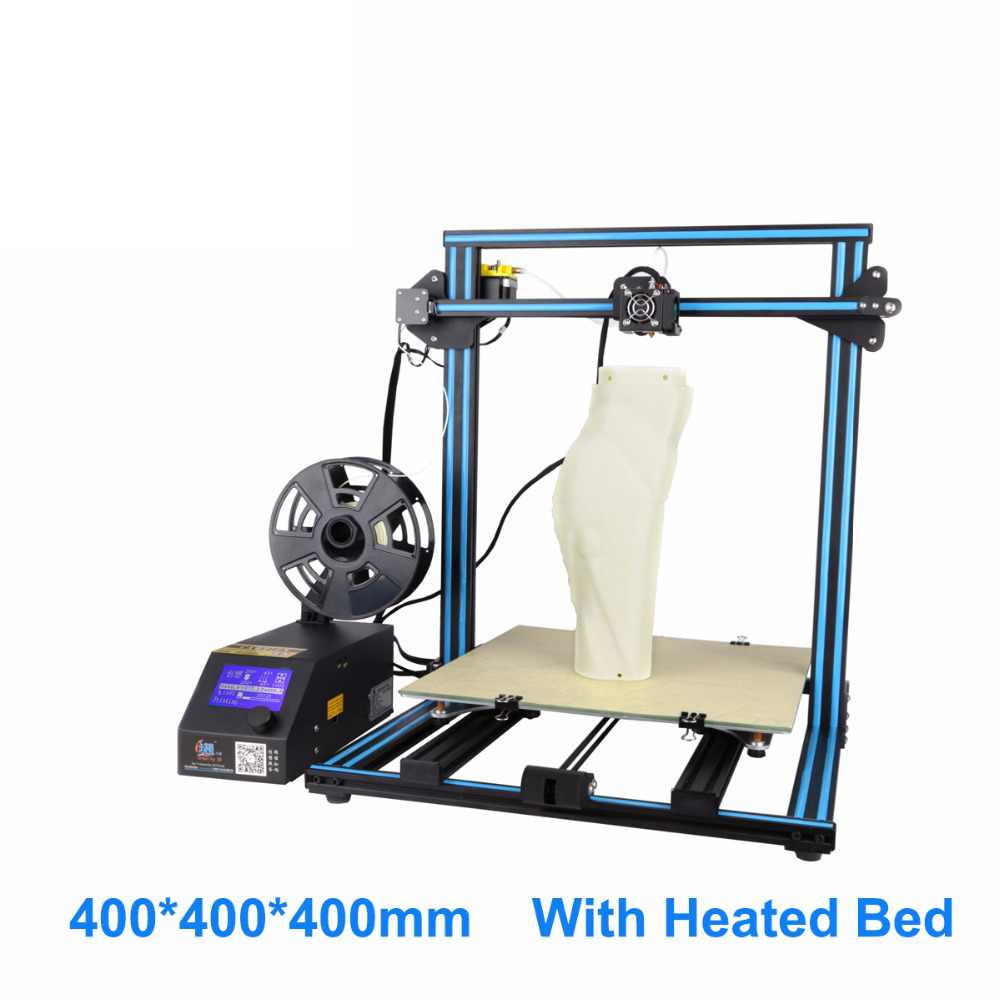

Carbon fiber 3D printing is coming down in price. I haven't seen a homemade lower made from it yet. We have a couple of 3D Printers. They are both based on open source platforms so that they can use a wide variety of filament and can be customized. The filament with the highest tensile strength that I have used is a nylon based “alloy’. I also have used filament with both powdered wood and metal suspended in the plastic filament. They give the object that you produce the appearance that it is made from wood or metal, but the wood and metal do not make the object “stronger”.

Creality CR-10 S4 printer which I can highly recommend.

The challenge designing objects produced with additive 3D printing on the types of printers that we have is that no matter what material you choose to print with, they are always have much less strength between the layers. What you have is a product that is similar to a piece of wood. It can easily be split with the grain even if it is very strong across multiple layers.

I designed a venturi with hollow chambers that I bolt on to a standard portable generator to “convert it to natural gas or propane. The first prototypes failed within a few hours because the vibration from the small engine would cause the layers to separate and break at the flange. When I changed the orientation of the layers by printing them on their side they last indefinitely.

Carbon fiber derives much of its strength through the long fibers in the layup. That cannot be reproduced when using a filament that has the same chemical makeup but is basically powder suspended in a plastic base. There is currently no way I know of or can conceive to reproduce the fibers in an additive 3D printer. If you need that type of strength at this time you need to use a CNC type milling machine and start with a block of material that has the properties that you desire.

"6040" desktop type CNC machine for subtractive production, which I have been pining for.

To: w1n1

This weight can cause the shooter to lean backwards to compensate, and in turn, makes these heavier guns un-enjoyable.Makes it harder to target blue helmets, too.

12

posted on

06/18/2020 10:06:00 AM PDT

by

JimRed

(TERM LIMITS, NOW! Build the Wall Faster! TRUTH is the new HATE SPEECH.)

To: DesertRhino

Marines somehow manage to shoot at 500 yards with iron sights with that terrible “heavy” trigger. Anyone who complains about the standard AR trigger doesn’t know how to run a trigger. I’m a former Marine and qualified expert many times with the M-16 and I’ll still tell you trigger sucks. The first thing I did to my ARs was to put in decent triggers.

I’ve never “run” a trigger, is that like running a lawn mower?

13

posted on

06/18/2020 3:48:56 PM PDT

by

GaryCrow

To: w1n1

Yep. A carbon fiber lower would help this one immensely.

To: Billthedrill

Holy cow! That thing looks like it took a tumble thru the ARfcom "Equipment Exchange" with a $hit magnet attached to it!

Wish I could claim it, but it's some other ARfcommer's tagline. d;^)

15

posted on

06/18/2020 7:17:29 PM PDT

by

CopperTop

(Outside the wire it's just us chickens. Dig?)

To: Billthedrill

Evike, (an airsoft gun retailer) has a similarly equipped offering.

It’s called “Optic Thunder”!

16

posted on

06/18/2020 8:00:27 PM PDT

by

Jotmo

(Whoever said, "The pen is mightier than the sword." has clearly never been stabbed to death.)

To: GaryCrow

Running it is a term that is probably from before your time. And it doesn’t suck. In the old corps people had no issue with it.

17

posted on

06/18/2020 8:44:01 PM PDT

by

DesertRhino

(Dog is man's best friend, and moslems hate dogs. Add that up. ....)

To: Magnum44

In addition to AD concerns, military primers are less sensitive owing to the desire to reduce accidental ignition during rough handling and shipping. Heavier hammer springs are required to insure reliable primer ignition of these denser primers, which means more trigger pull weight.

18

posted on

06/18/2020 9:52:51 PM PDT

by

DMZFrank

To: DesertRhino

Running it is a term that is probably from before your time. And it doesn’t suck. In the old corps people had no issue with it. I was in the "old corps". It's a fair bet I was way before your time and nobody ever called it "running" a trigger, that's something you hear out of the mall ninjas on the snipershide forum. The M-16/AR-15 trigger makes the rifle go bang and it's safe, but no one who has ever done any precision shooting would say anything other than the mil spec trigger sucks. There's a reason companies like Geissele sell so many replacement triggers.

19

posted on

06/19/2020 9:13:24 PM PDT

by

GaryCrow

Disclaimer:

Opinions posted on Free Republic are those of the individual

posters and do not necessarily represent the opinion of Free Republic or its

management. All materials posted herein are protected by copyright law and the

exemption for fair use of copyrighted works.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson

Since the weight of an AR-15 rifle varies from manufacturer to manufacturer and model to model, it can sometimes be an undesirable element for women who shoot them. A fully accessorized AR-15 can weigh upwards of 10 or more pounds with a fully loaded, high-capacity magazine.

Since the weight of an AR-15 rifle varies from manufacturer to manufacturer and model to model, it can sometimes be an undesirable element for women who shoot them. A fully accessorized AR-15 can weigh upwards of 10 or more pounds with a fully loaded, high-capacity magazine.