Silicon chip with porous surface next to the special furnace where it was coated with graphene to create a supercapacitor electrode. Credit: Joe Howell / Vanderbilt

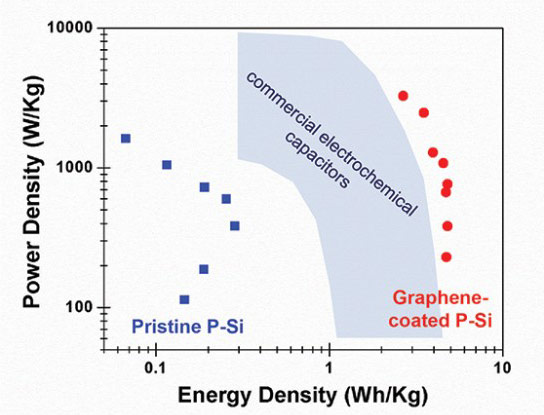

Graph displays the power density (watts per kilogram) and energy density (watt-hours per kilogram) of capacitors made from porous silicon (P-Si), graphene-coated porous silicon and carbon-based commercial capacitors. (Cary Pint / Vanderbilt)

To: ShadowAce

2 posted on

10/24/2013 1:12:29 PM PDT by

Red Badger

(The only way to defeat liberalism is to give them everything they want......then pick up the pieces.)

To: Red Badger

I wonder what it could do if you attached it to a DeLorean.

4 posted on

10/24/2013 1:18:24 PM PDT by

noiseman

(The only thing necessary for the triumph of evil is for good men to do nothing.)

To: Red Badger

material scientists? Whats that? A scientist that studies

material?

6 posted on

10/24/2013 1:20:45 PM PDT by

Slambat

To: Red Badger

That will make your flashlight recoil.

To: Red Badger

“improved energy densities by over two orders of magnitude compared to those made from uncoated porous silicon and significantly better than commercial supercapacitors.”

Cool! Big jump!

To: Red Badger

This is a continuation of the work pioneered by Rice and UCLA (the latter who discovered how to cheaply produce graphene) and shows great promise. The biggest problem I see is the safety factor of using high storage capacitors. The ability of capacitors to charge quickly also allows them to discharge quickly so a shorted capacitor basically explodes.

To: Red Badger

The graph shows a power density of around 4 W-h/kg. Lithium-ion batteries are 100–265 W·h/kg.

15 posted on

10/24/2013 1:47:49 PM PDT by

PapaBear3625

(You don't notice it's a police state until the police come for you.)

To: Red Badger

What is the comparison between the best super-capacitors and this?

18 posted on

10/24/2013 1:51:57 PM PDT by

sr4402

To: rdb3; Calvinist_Dark_Lord; Salo; JosephW; Only1choice____Freedom; amigatec; Still Thinking; ...

19 posted on

10/24/2013 1:52:35 PM PDT by

ShadowAce

(Linux -- The Ultimate Windows Service Pack)

To: Red Badger

They move through the graphene as a wave. It’s a wave! The moment to applaud would be now.

To: Red Badger

That graph shows grapheme caps topping out at about 4.5 Wh/Kg energy density.

Just for perspective, the best lithium polymer batteries deliver about 250 Wh/Kg.

The power density for supercaps is pretty good though, as is their longevity.

28 posted on

10/24/2013 3:20:10 PM PDT by

Steely Tom

(If the Constitution can be a living document, I guess a corporation can be a person.)

To: Red Badger

Will Dr Pint name the consortium to exploit this nanotech “Pint-sized materials”?

29 posted on

10/24/2013 5:01:02 PM PDT by

NonValueAdded

(Occupy the DC Mall - take back the monuments)

To: Red Badger

Graphene - like transistors were in the 50’s....

35 posted on

10/25/2013 7:32:27 AM PDT by

GOPJ

(Self-respect is the root of discipline...dignity grows with the ability to say no to oneself-Heschel)

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson

![]()