Posted on 12/03/2022 8:44:58 PM PST by SeekAndFind

Apple Inc's massive exposure to Chinese manufacturing has left it with production shortfalls of iPhones due to Beijing's harsh virus containment policies and unrest at a major factory in central China operated by Foxconn. A new report shows the iPhone maker's retreat from China is accelerating.

WSJ said Apple is "telling suppliers to plan more actively for assembling Apple products elsewhere in Asia, particularly India and Vietnam, they say, and looking to reduce dependence on Taiwanese assemblers led by Foxconn."

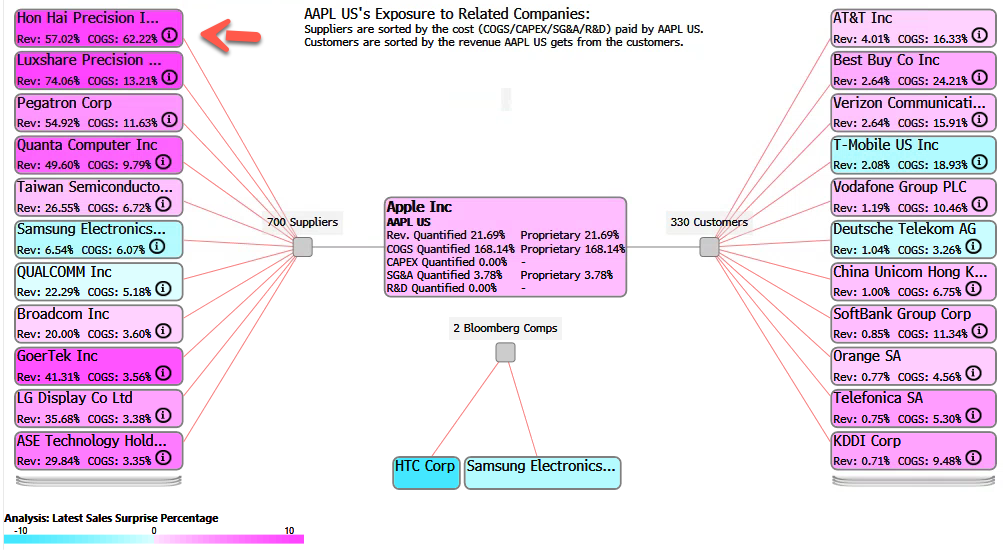

Apple's supply chain data indicates China is the iPhone maker's primary location. Market research firm Counterpoint Research recently noted 85% of the Pro lineup of iPhones is made in Foxconn's giant city-within-a-city factory in Zhengzhou.

The factory has been hit with Covid-19 restrictions and unrest in recent weeks and months, leading to a production shortfall of 6 million iPhone Pros by the end of the year.

"Apple no longer feels comfortable having so much of its business tied up in one place, according to analysts and people in the Apple supply chain," WSJ noted.

"In the past, people didn't pay attention to concentration risks.

"Free trade was the norm and things were very predictable. Now we've entered a new world," Alan Yeung, a former US executive for Foxconn, said.

People familiar with Apple's supply chain said that not all production would be shifted outside China. However, the remaining production in China will draw on a larger pool of assemblers, not just Foxconn. They said Luxshare Precision Industry Co. and Wingtech Technology Co. are two companies in line to receive more business from Apple.

As for the shift out of China, people involved in the discussions said Apple is telling manufacturing partners to look at other countries.

However, Apple has spent decades interweaving its supply chains within China, and change won't come overnight.

"Finding all the pieces to build at the scale Apple needs is not easy," said Kate Whitehead, a former Apple operations manager who now owns her own supply-chain consulting firm.

Ming-chi Kuo, an analyst at TF International Securities who follows the supply chain, said Apple's longer-term objective is to ship 40% to 45% of iPhones from India. And suppliers said Vietnam could soon be a significant player in manufacturing other Apple products such as AirPods, smartwatches, and laptops.

The bigger trend is the fracturing of the global supply chain. US firms realize China's zero Covid policy and shutdowns, along with heightened geopolitical risk across the region, are bad for business and recently outlined in the American Chamber of Commerce in Shanghai's latest survey of US firms in China found a near doubling of respondents over the past year that are slashing investment.

I feel the need to point out something to the obviously geographically challenged folks at Apple.

Any supply line that runs through an arc from the Straits of Malacca through Guam to Japan is going to be shut down to commercial traffic the moment we get a ‘Special Military Operation with Chinese characteristics’.

They could try making their products in the USA.

This should have been encouraged and even demanded (with both rewards and arm twisting) by the last administration.

Foxconn is Taiwanese. They are already manufacturing for Apple in India. My guess Foxconn will do the same in other Asian nations. Vietnam?

_______

Nikkei Asia —Taiwanese Apple supplier Foxconn will start to assemble the iPhone 12 in India, marking the first time the flagship device has been made outside of China. Apple’s new 5G-enabled iPhone will be produced at a factory in the southern Indian state of Tamil Nadu that already makes older models.

Foxconn Set to Make IPhone 12 in India, Shifting From China

They are late to the party and still not drinking the koolaid. Many others abandoned China during the Trump years when it became crystal clear that relations were deteriorating and they realized the value of diversifying. Others got religion in 2020 when China shut down (and stayed shut down).

Unfortunately for Apple the chicoms have them by the balls as Chinese consumers are a massive market. So Apple is unwilling to risk offending their chicom overlords and thus moves slowly on the reset. In the long run, that will prove more costly.

The factory has been hit with Covid-19 restrictions and unrest in recent weeks and months, leading to a production shortfall of 6 million iPhone Pros by the end of the year.

“Apple no longer feels comfortable having so much of its business tied up in one place, according to analysts and people in the Apple supply chain,” WSJ noted.

“In the past, people didn’t pay attention to concentration risks.

“Free trade was the norm and things were very predictable. Now we’ve entered a new world,” Alan Yeung, a former US executive for Foxconn, said.

Seems they only care about their bottom line and aren’t a bit concerned with all the life saving China is engaged in...

/S

Yeah, they said they were doing that back in 2020 too

Didn’t a certain President warn them about this a few years ago?

I had to wait almost two months for my iPhone 14 Pro Max, finally got it a few weeks ago. I never had to wait to get a new iPhone before. So the supply chain issues with Apple are real.

The stupidity of our “brilliant” elites is incomprehensible.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.