Posted on 02/29/2020 10:33:56 AM PST by blam

One week ago, ahead of today’s Chinese data release which would for the first time capture the devastation from the coronavirus pandemic, we wrote that “to those who have been following our series of high-frequency, daily indicators of China’s economy, it will probably not come as a surprise that the world’s second biggest economy has ground to a halt, its GDP set to post the first negative print in modern history. To everyone else who is just now catching up, we have some news: it’s going to be bad.”

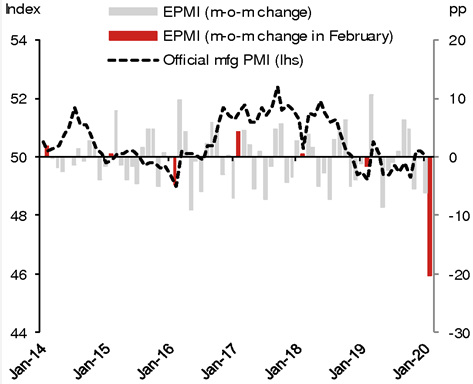

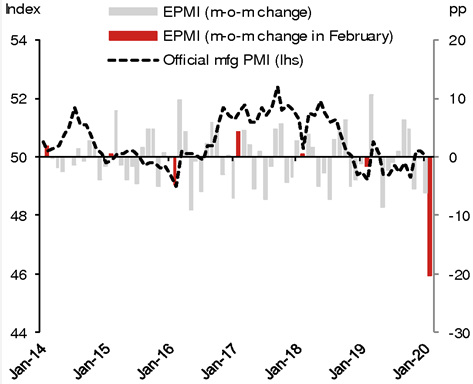

Specifically, we said that ahead of official Chinese economic data which will soon start capturing the period when the coronavirus crippled the country’s economy, Nomura’s Chief China economist Ting Lu pointed out that China’s Emerging Industries PMI (EPMI), which gauges momentum in the country’s high-tech industries and is closely correlated with official manufacturing PMI, slumped to 29.9 in February (from 50.1 in January!), its lowest-print on record, which was a “pure reflection of the devastating impact of the COVID-19 outbreak.”

What would this mean for the closely followed China manufacturing PMI? As Nomura added, "even adjusting for seasonality and expected progress in business resumption in the coming week, we estimate the official manufacturing PMI could drop to a range of 30-40 in Feb."

In retrospect, it turns out that Nomura's dire forecast was optimistic, because moments ago China's National Statistics Bureau reported the latest, February PMIs and they were absolutely catastrophic:

(snip)

(Excerpt) Read more at sgtreport.com ...

Hey what? I don’t want to be culled...

Excellent, informative, and enjoyable (as long as one is not facing Chinese’ assassination) post.

That’s a VERY good point.

Some things will help, such as being able to “print” prototype parts, near instantaneous communications, and so on, but, many other things - environmental clearances to build a new plant, for example - more than counter such time savers.

In a crisis type shortage, a lot of regs might get waived (may require throwing some EPA types and judges to the [figurative] catfish), but, problem is, we are already into the shortage by then...

My ENTIRE department was outsourced, you can’t “outsmart” that you idiot.

Bingo...we remain the arsenal of democracy and as immigration dilutes the culture in Europe we stand increasingly on our own. We need to be self sufficient, perhaps within the English speaking world.

Yes, the shoe manufacturers in my area tell me we can’t even manufacture the grommets on a shoe any longer.

So, what the heck industry did you do costing work in?

In the industry I was in (light manufacturing, 300+ employees), regs or new regs on our US parts vendors (metal, molded paper, plastic, impregnated cloth, etc.) commonly cost us several % of the total production cost, which was passed on to our customers: They then added pretty much a straight multiplier on their end, to determine retail "street price". That doesn't even include our own internal compliance costs: Compliance officer, equipment, added labor (production line, production engineering, sometimes design engineering), maybe a new (and invariably more expensive or process-intensive) adhesive needed. And so on. Final street price too high? Usually we then had to take something "out" of the design (performance, quality, US parts vendor(s)...) Or "just" redesign the whole product. Or watch the customer go to China or go out of business. Me: "Hey boss, I think I'm gonna need a new bottle of Tylenol." "What's that?" "Ok, I'll pick up two for you."

This is by no means to say that all regs are unnecessary. But, the way the gov't goes about it is, more often than not, insane.

FWIW, our margins were typically 10% or less: On a few occasions we basically manufactured certain items at cost just to keep good employees. But no business can function at zero margin forever for the majority of its production. Unless it is subsidized, of course...

"Anti-American worker screed" is YOUR screed.

Get a different set of skills which are very difficult to out source. Reason your department got out sourced is because the skills were available in huge quantity for a cheap price.

Like I told you again and again and again, the skill set I acquired through a master’s degree in mechanical engineering plus hard effort to learn more skills in the real world of design and manufacture of heavy machinery, it was impossible for my company to lay me off even when 30-40% of staff was getting laid off during some years. When I finally resigned after 23 years in the outfit, the president calls me in his office, and tells me “if you ever wish to come back here, the door is wide open for you”.

So stop posting the same thing over and over. And learn some skills which are hard to replace. Computer programmers and IT skills are dime a dozen the world over.

Paul, you couldn’t be more right. After 23 years in private sector I joined a department of energy funded research lab to design experimental equipment the scientists needed for research. The regulations were horrible. If the crew needed to dig a simple ditch to place a post, we had to file a report proving we had taken all the safety precautions. There had to be others present in case the digger injured himself, complete with procedures to execute first aid. 99.9 out of 100 times there never was a problem, but the paperwork was compulsory 100% of the time.

That's a big problem with supply chains collapsing... It's not that a company can't get some parts - it's that the one or two parts coming out of China make the whole production impossible. This could get weird.

Those globalists don’t want their money to stop, they may be rich but they have obligations and if there is no product for their businesses to sell, they lose money...inflation goes up, the value of the wealth goes down and stock prices drop. Very rich men in 1929 became pauperized overnight. So could 2020’s “rich” men. They’ll make changes if the “China Economic Syndrome” continues for long!

Sad but true! I guess OSHA needs to perpetuate their power and keep their jobs.

Under new leadership in the EPA some of these bureaucratic regulations are starting to be rolled back.

That does not equate to several % of retail cost. A percent of production cost, say production cost is 10% of the retail price, is meaninglessness to the retail consumer which will nary notice. In this case a 2% increase in the cost of production because of regulations would come out a .2% increase at retail. Not 2% but .2%. For that "savings" we, American taxpayer and patriot, get a closed factory and destroy an entire towns economic engine and financial viability? NO WAY....

This type of of pin-headed thinking on your part is why the USA needs a VERY HIGH PROTECTIVE TARIFF. Stop the insanity...

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.