Skip to comments.

'Wiki Weapon Project' Aims To Create A Gun Anyone Can 3D-Print At Home

forbes.com ^

| 23 August, 2012

| Andy Greenberg

Posted on 08/24/2012 8:35:19 AM PDT by marktwain

Cody Wilson has a simple dream: To design the world’s first firearm that can be downloaded from the Internet and built from scratch using only a 3D printer–and then to share it with the world.

Earlier this month, Wilson and a small group of friends who call themselves “Defense Distributed” launched an initiative they’ve dubbed the “ Wiki Weapon Project.” They’re seeking to raise $20,000 to design and release blueprints for a plastic gun anyone can create with an open-source 3D printer known as the RepRap that can be bought for less than $1,000. If all goes according to plan, the thousands of owners of those cheap 3D printers, which extrude thin threads of melted plastic into layers that add up to precisely-shaped three-dimensional objects, will be able to turn the project’s CAD designs into an operational gun capable of firing a standard .22 caliber bullet, all in the privacy of their own garage.

(Excerpt) Read more at forbes.com ...

TOPICS: Business/Economy; Constitution/Conservatism; Culture/Society; News/Current Events

KEYWORDS: banglist; constitution; print; wikiweapon

Navigation: use the links below to view more comments.

first previous 1-20, 21-40, 41-60, 61-69 last

To: marktwain

The Second Amendment was the original recognition of real power to the people. And it would be deliciously ironic if the power of the First Amendment would eventually come to reinforce tht of the Second, in a wy that the founders might not have anticipated, but which surely would have delighted them.

Perhaps, like Ben Franklin, I may start calling myself a *Printer.*

61

posted on

08/25/2012 10:52:36 AM PDT

by

archy

(I'd give my right arm to be ambidextrous!)

62

posted on

08/25/2012 10:55:17 AM PDT

by

Titan Magroyne

(What one person receives without working for, another person must work for without receiving.)

To: LucianOfSamasota

They would need a metal barrel in any event, wouldn’t they? The barrel of the 12-gauge model 59 Winchester shotgun was of fiberglass with a metal liner mounted on an aluminum receiver. The Armalite AR-7 .22 survival rifle, now made and sold by Henry, has an aluminum receiver and barrel with a thin rifled steel liner. Other adaptations of other materials,including ceramics,are possible.

During the Second World War, some barrels for some productin versions of the British STEN submachinegun wer made of a flat stamping that was then milled with grooves at an acute angle, the metal strip then being formed around a mandrel and fusion welded into a prerifled tube, ready for use after a chambering reamer cut the barrel for the apropriate cartridge, almos always he 9mm Parabellum round still very much in use. It cost more to manufacture the seven magazines that accompanied each gun than it did to build te guns themselves.

63

posted on

08/25/2012 11:05:13 AM PDT

by

archy

(I'd give my right arm to be ambidextrous!)

To: BipolarBob

64

posted on

08/25/2012 11:18:23 AM PDT

by

archy

(I'd give my right arm to be ambidextrous!)

To: ArrogantBustard; Lady Jag

The “ink” is dirt cheap. It used to be said in the newspaper buisness that people were fools to try to throw mud at a publisher who bought ink by the barrel. There could now be a completely new meaning to that phrase.

65

posted on

08/25/2012 11:22:44 AM PDT

by

archy

(I'd give my right arm to be ambidextrous!)

To: Inconvenient Truthteller

A firearm made from extruded "thin threads of melted plastic"? Two words: Darwin Award That's prettty much what they said about Eugene toner's first military rifle designs utilizing aluminum refined from bauxite ore, which is essentially just the right kind of dirt.

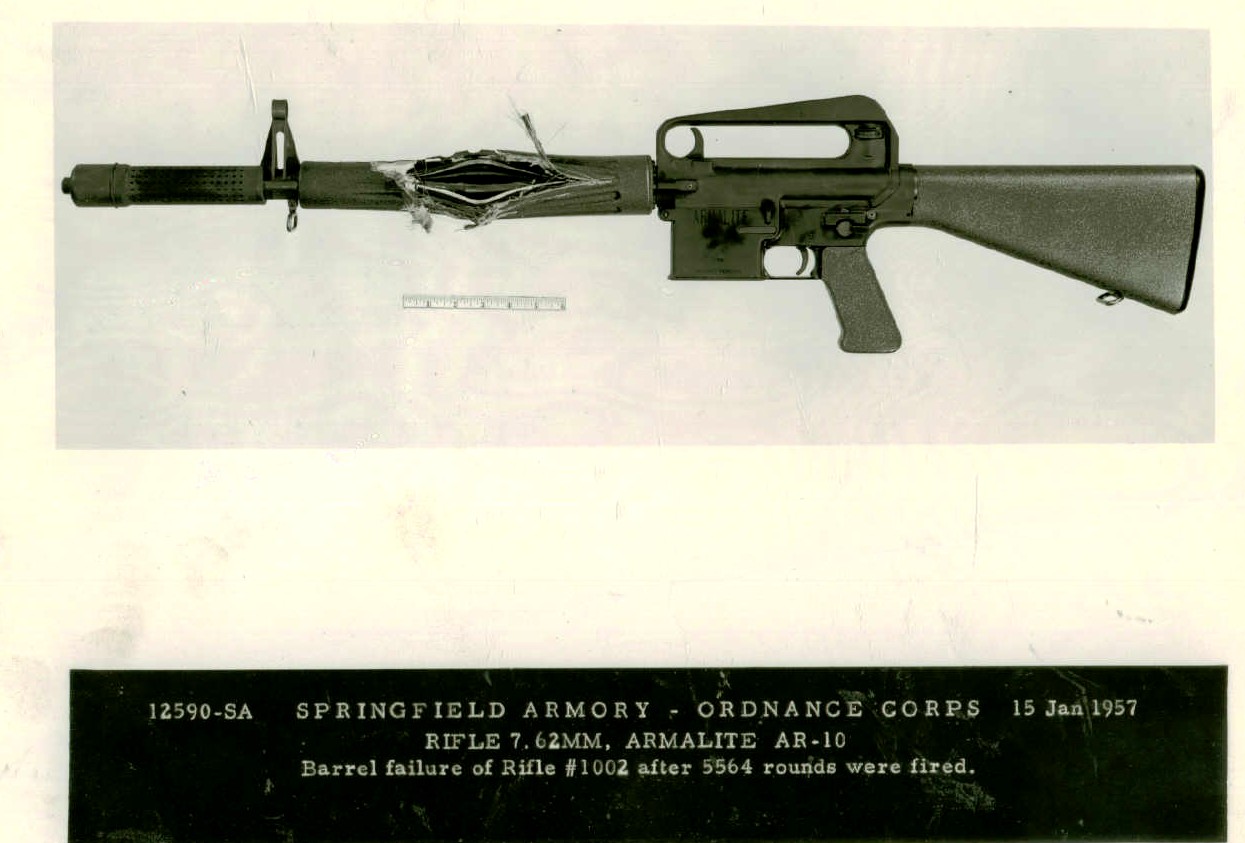

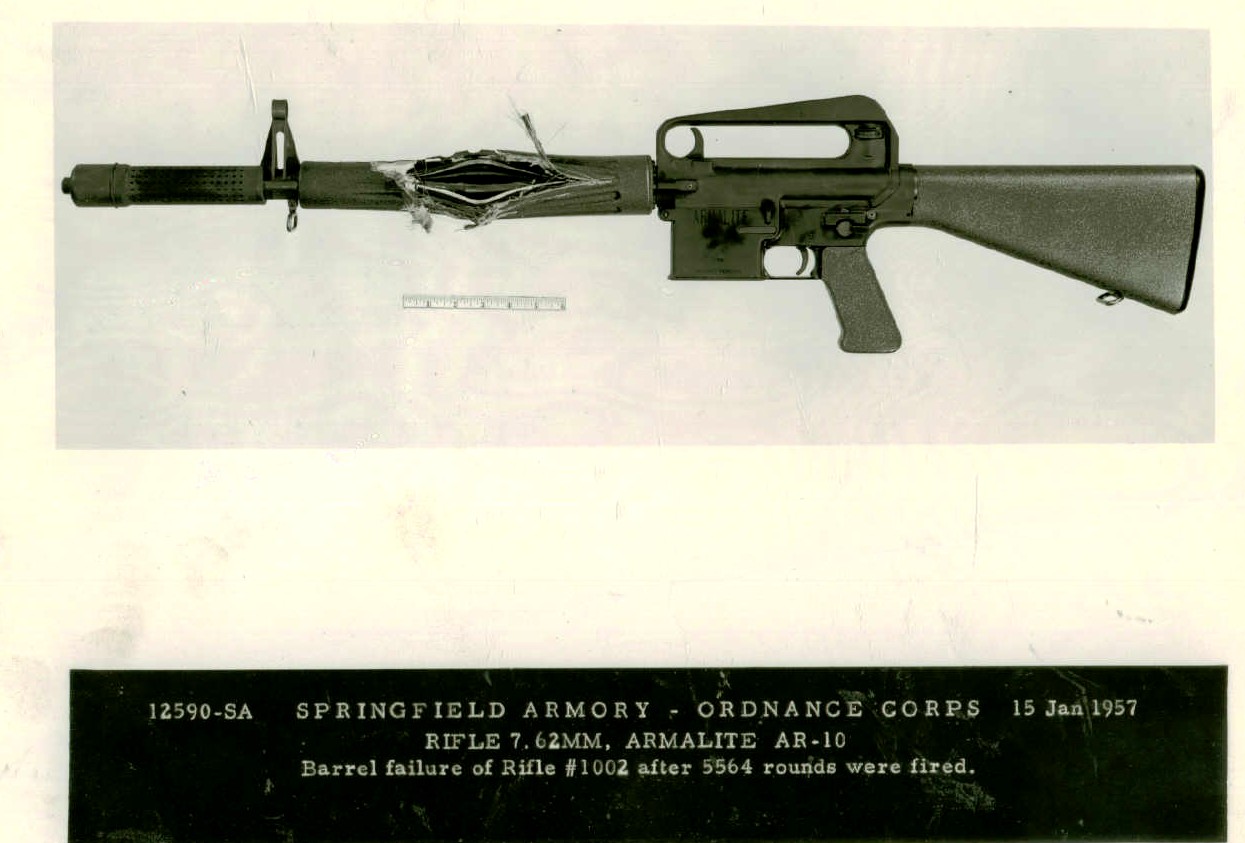

We've got a while to go before the all-plastic barrel becomes a reality, however. Ceramic is a real possibiulity though, and steel-liner fitted aluminum has been with us for some time now, despite early setbacks.

66

posted on

08/25/2012 11:32:24 AM PDT

by

archy

(I'd give my right arm to be ambidextrous!)

To: archy

Good work!

The use of the flashcube percussion unit is an inspired bit of practical engineering.

To: archy

Also lots go EDM and CNC programs laying about. Bench top 5 axis solutions abound......

68

posted on

08/25/2012 2:39:51 PM PDT

by

Squantos

To: All

69

posted on

08/25/2012 2:41:19 PM PDT

by

musicman

(Until I see the REAL Long Form Vault BC, he's just "PRES__ENT" Obama = Without "ID")

Navigation: use the links below to view more comments.

first previous 1-20, 21-40, 41-60, 61-69 last

Disclaimer:

Opinions posted on Free Republic are those of the individual

posters and do not necessarily represent the opinion of Free Republic or its

management. All materials posted herein are protected by copyright law and the

exemption for fair use of copyrighted works.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson