Posted on 04/07/2020 5:43:36 PM PDT by NoLibZone

A team at MIT developed a ventilator that could be built with $100 dollars worth of parts — a fraction of the average $30,000 cost most machines take to manufacture, according to a report by SciTechDaily.

The innovative design of the machine relies upon a bag-valve resuscitator, a piece of equipment found in bulk at most hospitals to help patients breathe, the report said.

Ventilators are one of the most in-demand medical items at the moment amid a worldwide shortage due to the coronavirus.

The team, MIT E-Vent, which consists of doctors, engineers, and computer scientists, decided to fervently revisit the building of an emergency ventilator machine, which began as a project in an MIT class, SciTechDaily reports.

The bag-valve resuscitator, also known as an Ambu bag, is used by hand to pump air into the lungs of a patient, according to the report. The design of MIT E-vent's machine pumps the Ambu bag mechanically in order to run for days, since just a two-week period could require more than one million cycles of the machine.

While the team plans to publish the design online in order to contribute to a wide-scale ramp-up of the device's production in order to help the worldwide storage, they stressed that the design is not meant for anyone to build — it's intended for experienced clinical engineers to help expand manufacturing, according to the report.

MIT E-vent emphasized the technical nature of the machine, as it must be able to adjust the air and pressure given to a patient to fit their exact needs and must be relied upon to operate continuously since machine failure could be deadly, according to SciTechDaily.

The team is waiting to receive feedback from the US Food and Drug Administration,

(Excerpt) Read more at businessinsider.com ...

How many patients could a single respiratory tech monitor if he/she had to manually look after all those parameters? 2? 5? 10?

I’d think the person monitoring those things manually would go batty in short order.

That’s the easy part!

ProtectOurFreedom wrote:

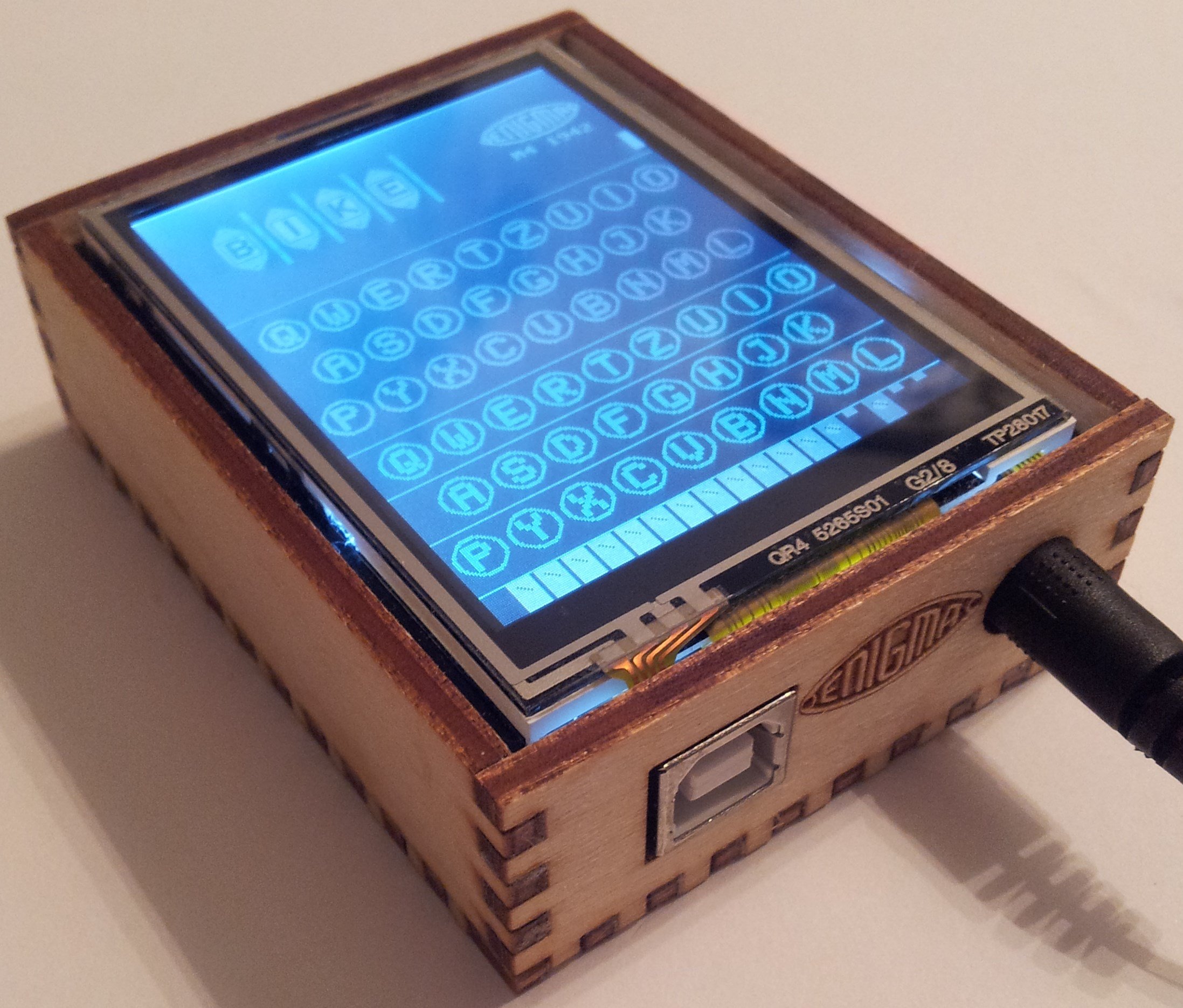

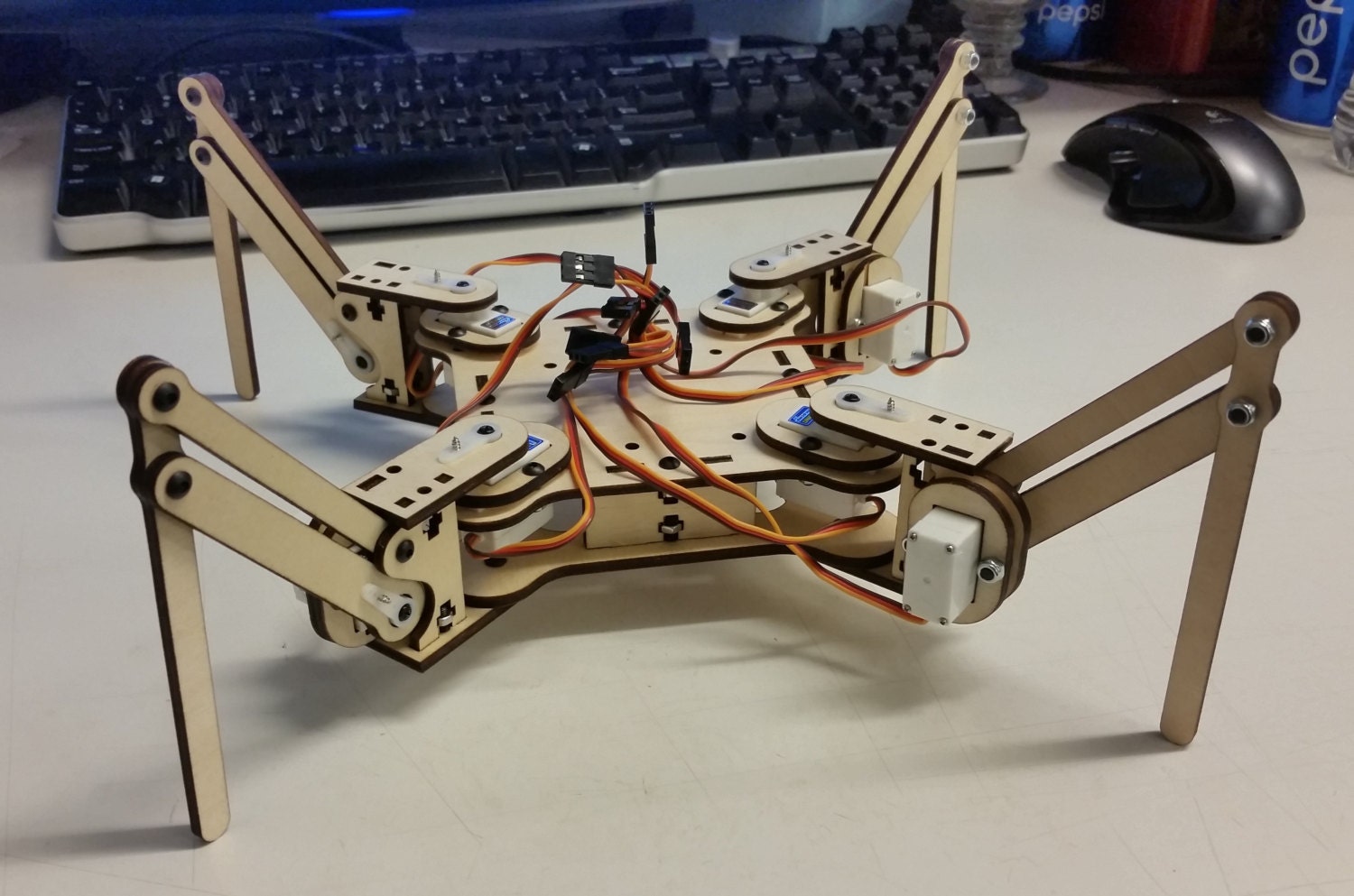

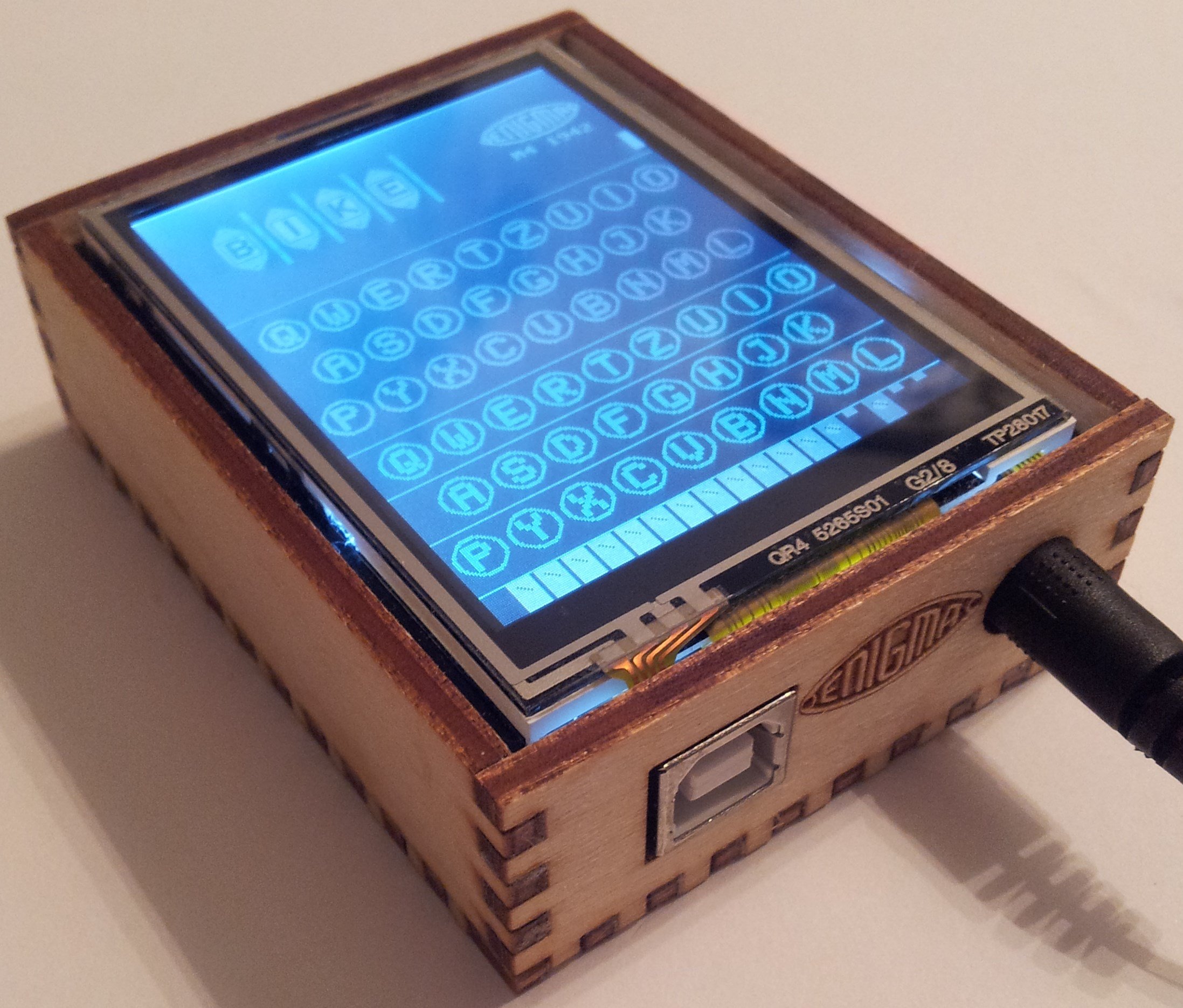

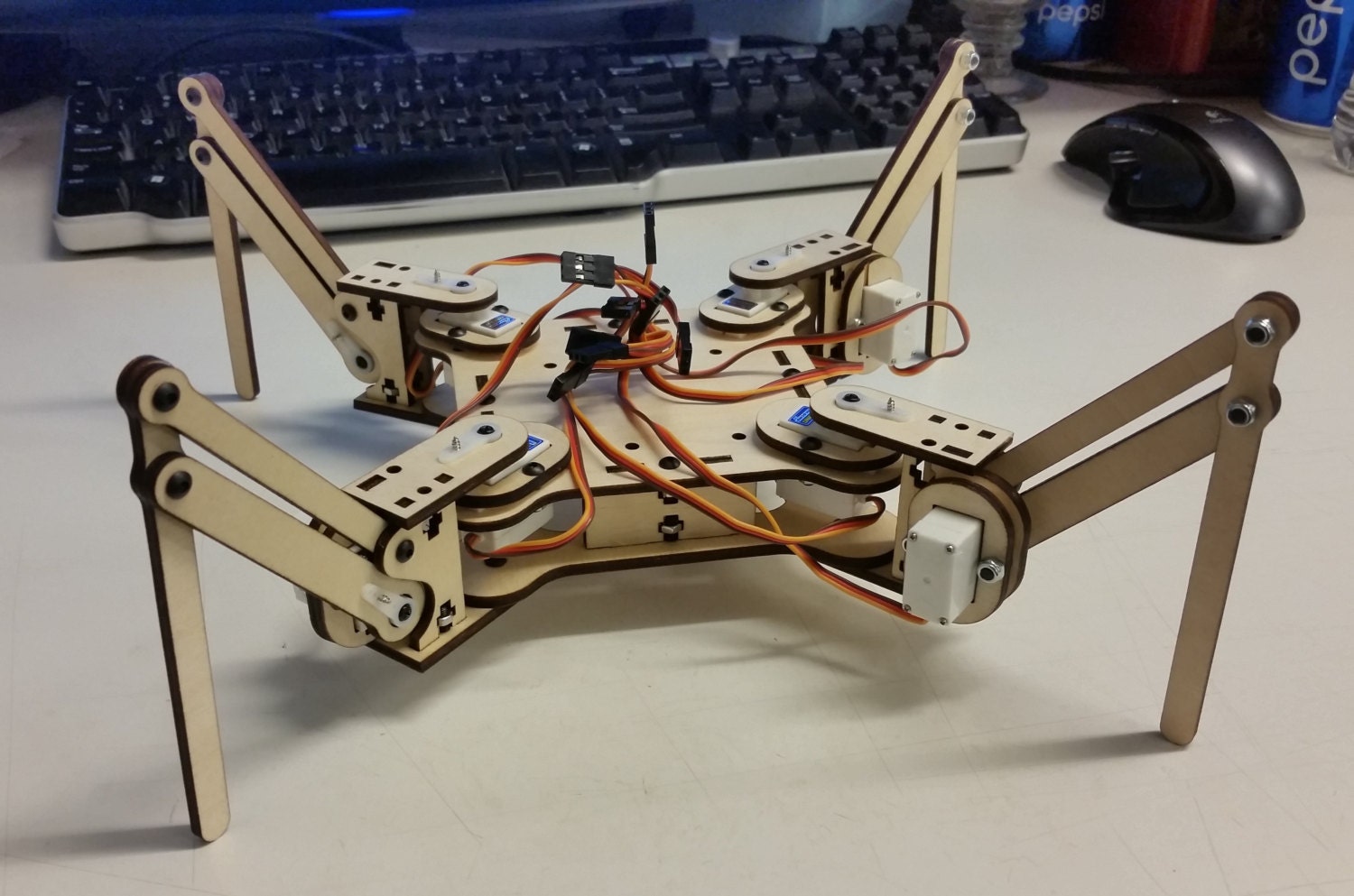

“Lot of 3D printed parts, off the shelf microcontroller, standard rack and pinion. Standard laser-cut thin plywood enclosure. Wonder what sensors they are using. Pretty darn cleve!

(Pic of invention)”

Great work, MIT !!!!

“Great work, MIT !!!!”

Rice U. objects to your post.

So what defines the mechanical cycle of this device.

Inhale and exhale most likely.

Glad that someone is actually getting a real, useable college education. Good luck to the MIT team, now and in their future.

They are one of the “solutions” which we have been waiting.

A wooden box like an Apple-1 computer.

Lots of “Maker” kits come with pre-cut thin plywood and interlocking edges like that.

They'll all be old men by the time they hear back.

Love the HHGTTG reference! Quite apropos as well.

Nice looking device. You couldn’t use that as is though. However, I do not believe there would be any way to sanitize the wood body. The body needs to be made of plastic.

It’s fast, easy and cheap to prototype cases using that notched plywood.

You are right, of course, that it cannot be sanitized or disinfected. Good point.

The developers spent their time on the core product proving it works. Once the innards and their configuration are finalized, they can package it up in a nice 3D printed shell case.

Fits our whole government.

Quite true. The wood case looks kinda cool IMO, even though it's not practical.

One cycle per second equals 1,200,000 in a 2 week period.

I’ve made things from old windshield wiper mechanisms.

Speeds adjustable; too.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.