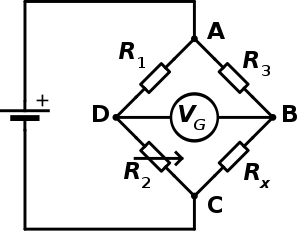

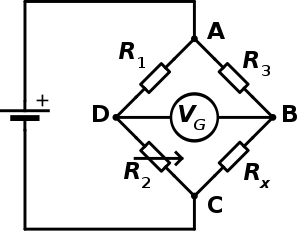

Zero current will flow through the galvanometer at the center if

Use a known-good gold bar or coin as your reference. If a supposedly identical bar or coin displays different resistance, then it is fake.

Posted on 09/18/2012 7:08:59 PM PDT by Perdogg

It is one thing for tungsten-filled gold bars to appear in the UK, or in Germany: after all out of sight, and across the Atlantic, certainly must mean out of mind, and out of the safe. However, when a 10 ounce 999.9 gold bar bearing the stamp of the reputable Swiss Produits Artistiques Métaux Précieux (PAMP, with owner MTP) and a serial number (serial #038892, likely rehypothecated in at least 10 gold ETFs across the world but that's a different story), mysteriously emerges in the heart of the world's jewerly district located on 47th street in Manhattan, things get real quick. Moments ago, Myfoxny reported that a 10-ounce gold bar costing nearly $18,000 turned out to be a counterfeit. The discovery was made by the dealer Ibrahim Fadl, who bought the PAMP bar in question from a merchant who has sold him real gold before. "But he heard counterfeit gold bars were going around, so he drilled into several of his gold bars worth $100,000 and saw gray tungsten -- not gold. The bar was filled with tungsten, which weighs nearly the same as gold but costs just over a dollar an ounce."

(Excerpt) Read more at zerohedge.com ...

The bars have passed the handheld XRF scans we are talking about.

http://silverdoctors.blogspot.com/2012/03/tungsten-filled-1-kilo-gold-bar.html

“In the biggest news we’ve broke since the JP Morgan whistle-blower stepped forward,

Australian Bullion Dealer ABC Bullion has contacted SD to advise that one of its suppliers has provided them photographic evidence of a tungsten filled 1 kilo gold bar discovered this week. The bar passed a hand-held xrf scan which showed 99.98% pure AU. The tungsten was only discovered when the bar was physically cut in half.

...”

The specific XRF device may not have been the correct one needed. The bottom line is that we know ONE TEST failed. Nothing more.

What makes you think they "hollowed out" the gold bars in the first place. Far simpler just to make a cast of the gold bar, make a mold, melt the gold, and pour it in over the tungsten bars. No need to "bore" anything.

All of the articles I have seen on these tungsten filled fakes say that they used a real gold bar and hollowed it out, or drilled it out.

They use a real gold bar from a reputable house because it ensures that they are getting real gold in their scam and it makes their fake almost undetectable.

The fake gold bar has a real seal and a real serial number and is correctly marked. They don’t have to try to duplicate any of that.

The hollowing out of real gold bars is what is really worrying folks. A cast fake would be much easier to spot. Duplicate serial numbers would be noticed.

“What makes it so devious is a real gold bar is purchased with the serial numbers and papers, then it is hollowed out, the gold is sold, the tungsten is put in, then the bar is closed up. That is a sophisticated operation.”

http://www.theblaze.com/stories/fake-gold-bars-discovered-at-store-in-midtown-manhattan/

Other distinguishing properties: tungsten has more than twice the electrical resistivity, and half the thermal conductivity of gold, so other tests can be devised that can be done with much simpler and less expensive equipment.

My paranoid side has me thinking that maybe these stories are a way to smoke out who has hidden gold assets, by setting up gold testing services, and having the IRS later visit the people whose gold was tested?

That's why mortgages and liens are supposed to be registered with the country, so that if I use my house as collateral for loan A, and then try to use it as collateral for loan B, the originator of loan B can check with the county and say "Hey! That house is already mortgaged!"

Zero current will flow through the galvanometer at the center if

Use a known-good gold bar or coin as your reference. If a supposedly identical bar or coin displays different resistance, then it is fake.

“What makes it so devious is a real gold bar is purchased with the serial numbers and papers, then it is hollowed out, the gold is sold, the tungsten is put in, then the bar is closed up. That is a sophisticated operation.”

No need for there to be "duplicate serial numbers". Just take a cast of the "real gold bar" with its original serial numbers, melt it, put the tungsten bars in the mold, and refill the mold. Casting can capture VERY fine detail. The gold volume replaced by the tungsten stays in the crucible. You pour that into a different mold, and sell that separately in a black market where no serial numbers are needed. But given the crudity of the pictured example and the very thin layer of gold over the tungsten, a PROPERLY SELECTED XRF unit would have no problem picking this geometry up. Judging from the photo, there is probably no more than a mm or two between the tungsten and the gold surface.

And as "PapaBear3625" points out, there are other physical properties that work. I suspect that ultrasound would also show things up. I'm sure gold and tungsten have drastically different sound transmission characteristics.

Yep. Tungsten velocity of sound = 5174 meters/second. Gold velocity of sound = 3240 meters/second. Ultrasound should show tungsten cores quite readily.

Probably much quicker to put the bar in a CNC machine and hollow it out, than it is to go through the molding and casting process. Then polishing up the cast bar carefully so as not to remove details or leave marks.

A CNC machine can probably hollow out the original bar in seconds.

I doubt these reputable houses are accepting these bars without doing their normal checks.

I think the pictures and vid clearly show that the gold was not poured around the tungsten bar. The tungsten bar is just inside the gold bar. Gaps can be seen where the fit is not perfect.

VERY unlikely. I've done a LOT of machining. Gold is !SOFT!. I haven't worked directly with gold, but other metals with similar physical characteristics that I have worked with (tantalum, lead) are VERY difficult to machine, even with CNC.

And I doubt that the sort of folks likely to be doing this have access to $100K CNC devices.

Making a casting mold, OTOH, is very "low-tech", cheap, and easy. The "hobby supplies" market probably has all anyone needs to do the necessary.

I’m sticking with what I can see. The tungsten bar does not fit exactly into the opening, so it can’t be a casting process.

I think we can see a logical progression.

They started off by drilling out the bars and inserting tungsten rods.

Then they figured out that they could hollow out the whole bar and insert a tungsten block.

Those gaps could have been formed quite easily when the bar was cut open, and in fact, I would expect to see precisely what is shown as a result of such an operation. The gold will deform, the tungsten will not. The result is a "gap" between the rod and the bar.

Well, I just hope Fort Knox isn’t full of tungsten, however they are doing it.

THAT, I don't think we have to worry about. The Feds have tools a LOT more sophisticated than XRF to test with, many of which are probably classified.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.