Posted on 06/20/2019 12:00:31 PM PDT by CharlesOConnell

I sat at a banquet a week ago with a guy who started up, worked, then sold his wholesale machinist biz, in our Sacramento CA suburb, Rancho Cordova. That’s where the money is, in the long run, but for young people starting out, a starting wage of $20, up to $26, is not chopped liver.

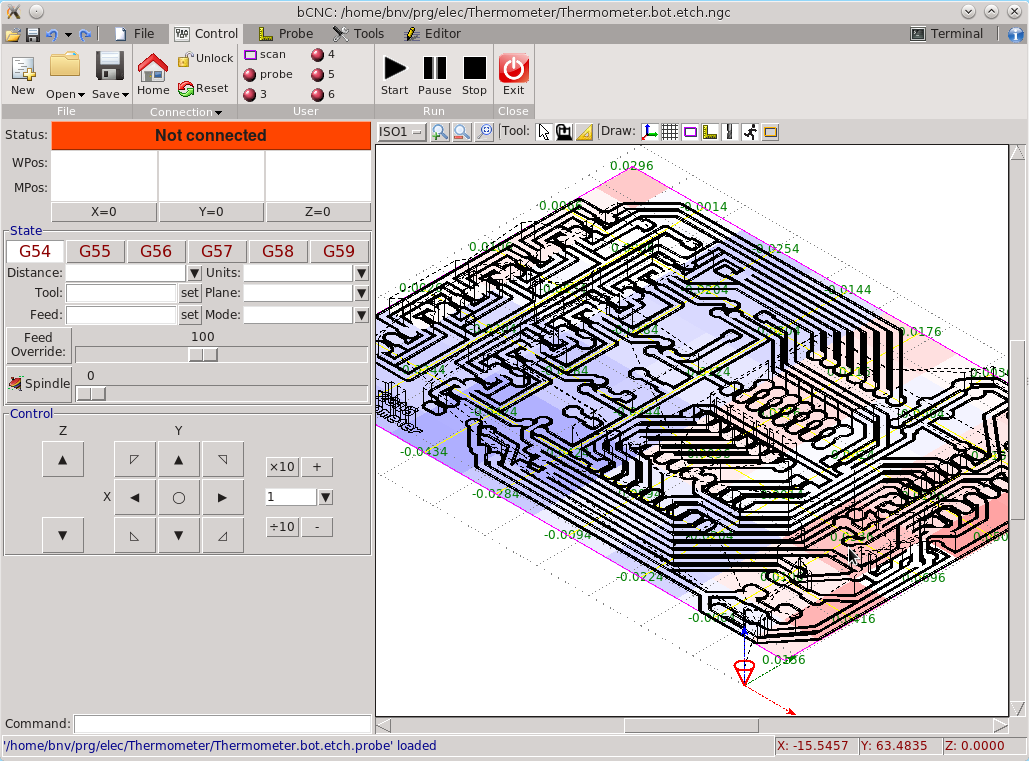

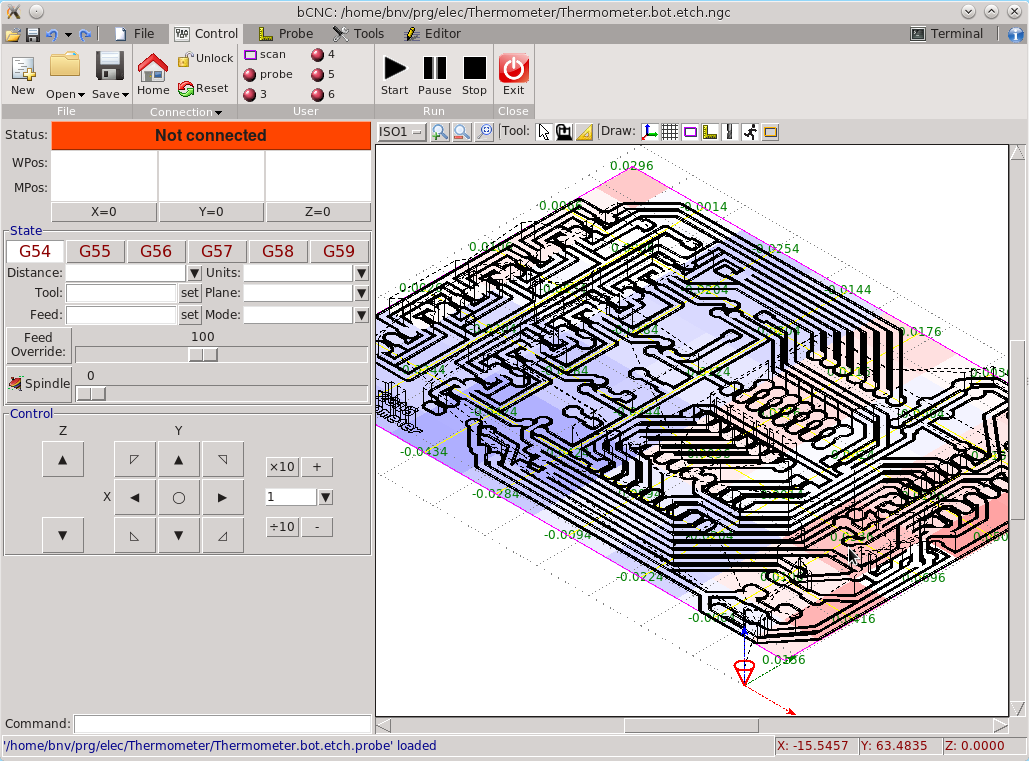

The happy-stance is that the computer control programming, like specialty AutoCAD, for 3D printing, at local education specialty clubs and for hobbyists, strongly resembles the professional computer application software for machinist vocational training, that now goes by the jargon CNC, for Computer Numerical Control.

Our area suffered a loss, in that industry outreach was dropped at one of the junior colleges, Sierra College, Rocklin north of Sacramento--where there is high tech like Oracle, Apple and Intel. When the instructor retired from a well established machinist program, the administrators neglected to hire a replacement. So the equipment was thrown out of a whole junior-college shop classroom area.

(The reason might be roughly like what happened at a big shiny monument building college, California State University, Sacramento, after they had demoted their Nursing College down just to a program. Similarly, after I spent 2 years pre-qualifying for a Piano Technician program, taking piano & music theory, one of the administrators wasn't sufficiently glorified by the initiative of the highly-skilled Piano Tech craftsman, an Examiner for the Piano Technician's Guild; the administrator quashed the program, planned to teach the 11 separate piano crafts that culminate in the $250,000 that it takes to customize a Steinway, with the declaration, "We're not running a school for mechanics". This Piano Tech was highly educated, as a graduate from the University of San Francisco music department, had his own recording studio, and ran a French Horn quartet.)

But it's a blessing for us that a CNC program is running in an adjoining junior college district, Cosumnes River College (no "consumption" or tuberculosis in the name). Their Sacramento City College has a CNC program, to the great benefit of our area's young students.

I picked up several older machine tools from a local tech school that was in the process of changing their focus to newer tech as well. Pennies on the dollar.

Knowing that the old iron is not generally found in industry today, I am in agreement that this change is necessary for training young people entering the workforce.

Well, our job shop has the opposite problem — very large CNC mills and lathes. The kids coming out of technical programs only know the new stuff.

What we really need is basic machine setup techniques, not programming skills. The new guys aren’t going to be writing their own programs until they prove that they can take a print and a program and return a finished part.

I am a casual acquaintance of an eighty something year old “machinist” of German descent who is perhaps one of the last keepers of the manual craft of using tool and die. His custom creations of the mind, hand, and micrometer are works of art. Yet he remains gainfully employed as an artisan of CAD and 3D printing. Better product is the result, but he wonders what might happen if world is somehow forced to resort to 1930’s technology to survive.

In German machinist vocational education programs years ago, a new student would get a vise, a file, a bottle of filing oil, and a piece of metal, that would be his whole Focus for the first year.

It makes more sense to teach CNC programming than it does cutting threads on a manual lathe, especially at the post-high school level.

As a machinist and teacher, I disagree. You need the fundamentals, the how, the why, Feeds, speeds, how metal behaves when you cut it, tool selection, etc. before you program. I tell my students, running a CNC machine is easy, being a CNC Machinist takes some work. If you don’t understand the foundation, you’ll never be more than an operator.

It makes more sense to teach CNC programming than it does cutting threads on a manual lathe, especially at the post-high school level.

x.x.x.x.x.x.x.x.x.x.x.x.

what you say makes some sense. while craftspersons can benefit from know the old machines and the old skills there is also a need to get people trained to use the new tech.

Same goes for welding - arc welding has been supplanted by a number of newer methods, but it probably will continue to have some value to those who have that skill.

CNC machines were in shops in the ‘70s (tape writing required—not hard). When the machines started to get a little loose and sloppy from wear, they were used without the CNC control. The more things change,...

I will risk suggesting that even though traditional machinists are much needed in the industry, there is an even greater demand for machinists that can integrate the old with the new.

Not mentioned yet are the newer forms of machining such as wire EDM and plasma cutting and the non-traditional materials encountered today such as plastics, ceramics and exotic metals to name a few.

Perhaps the field would benefit with specialists that have excellent communication skills instead of the grumpy old guy running the same machine for 20 years. (That would be me!).

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.