Posted on 11/27/2012 9:23:48 AM PST by Ernest_at_the_Beach

You may be familiar with some of the problems with flash, the most common one is write endurance. If you think of each flash cell as a tiny capacitor, shrinking it gives you less space to hold electrons, the layers holding in the electrons get thinner, and the space between cells lessens. That means with each write, the degradation, as a percentage, is higher so write lifetimes decrease as well.

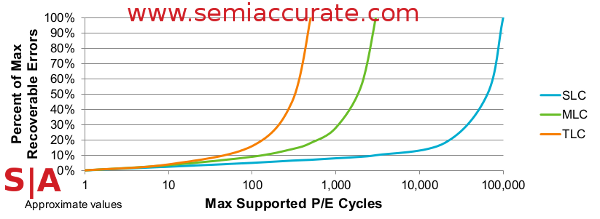

LSI says that the flash cells of 2004 held about 1000 electrons, today’s only hold about 100. Worse yet, old SLC flash was usually rated at 100K write cycles, today’s common MLC is around 4K cycles, and the newer TLC flash dies after 500 or so writes. All of these are what you might call a big problem.

You can see the problem

To make matters worse, with increasing density of chips, the number of I/O channels in a device goes down too. The example LSI used was a 128GB SSD, three years ago it took 32 4GB die to make one, now it only takes 8 16GB die. This means that the number of channels that can be simultaneously accessed goes from 32 to 8 as well. While this does mean potentially cheaper controllers, it also means bandwidth craters too, as does the ability to service parallel operations from a long queue of I/O operations. The net result is speed plummets, as do random I/Os.

(Excerpt) Read more at semiaccurate.com ...

Some physics about Flash Memory.

fyi

So, SSD’s should be purchased now?

But I will say that every one JUST assumed that it was automagically gonna knock out rotating memory devices.

Doesn't look that way to me....

Association for Information Systems (AIS)

My local computer store guys pointed out that there aren’t many SSD data recovery options compared to mag disks.

I’m waiting for the discovery that makes Supermans ice fortress valid. He was able to store light in crystals. That’s the technology we need.

Wow. Thanks for posting.

A lot of portable devices use only SSD memory. I hope the IO controllers mark expended cells rather then drop data.

If it wears out,...get a new one that will be even better...."we take cah andcan charge on credit cards".

It is all the wave of the futurre....watch the pom pom girls...

does this mean use one flash card for archiving and write only once, and one for work and replace each year?

(not really just one but just an exmple argument)

If important stuff for archiving is just written a minimum of times then, via this article, the write issue is avoided. (how many chips are able to be read after terrible accidents, tsunamis etc?)

See the review just above at post #13,...I scanned thru it....and it is mainly and speeds...performance....etc.

And the article notes that they are using the

For cost purposes????

Or maybe they know some of the same facts that LSI does,...some engineer probably does,,....but I bet the marketeers have a problem with using the OLD technology.

Real archiving of a long term....would be best using the CD with a metal layer....requires a special slightly higher powered CD burner and special CD's .

I think Newegg has both...label is M-Disk.

Looking for a link:

**************************EXCERPT********************************************

The materials and the write process used for the M-DISC were chosen with stability and longevity as the primary goals. These new materials enabled the use of a more durable data mark — a physical hole or pit that could be formed in the data layer. A much higher laser-power is used to write or create these physically changed pits in the data layer.

These physical pits have two main advantages over dye and phase-change-based optical media; the permanent physical movement of the material and the permanent optical contrast between light and dark spots. Movement of the material actually enhances the edge of the mark as shown in the nearby scanning electron microscope image. The nanometer scale location of the edges is critical to the retention of data, with the enhanced edges further building-in longevity. The other advantage is the excellent, permanent optical contrast that comes from making a physical mark. The difference in optical quality between the pit, where there is no material, and the areas adjacent to the pit, where the material remains, provides a definite advantage in retention of data and in ease of reading the disc long into the future. Essentially, pits are better and allows for readable data even after hundreds of years.

According to an independent report performed by the U.S. Department of Defense at China Lake, California, the M-DISC was the only optical disc tested that did not suffer data failure. The discs from Mitsubishi, Verbatim, Taiyo Yuden, Delkin and MAM-A all failed. None of the data was recoverable after the exposure cycle.

The patented data layer is composed entirely of inorganic materials and compounds including metals and metalloids. This layer is solid from room temperature to upwards of 500°C (932°F), and it is stable in the presence of oxygen, nitrogen, water, and other deleterious chemicals that may be found in ordinary storage environments.

The inorganic data layer materials undergo a physical change during the write process. When the data layer is irradiated by a focused laser, the intense heat generated causes the innermost layers to melt and to move away from the laser spot, creating a hole in the data layer as previously described. In contrast, the organic dyes used in typical DVD-recordable discs would merely decompose under the same thermal conditions.

Furthermore, when the melted portions of the M-DISC data layer cool after writing, the material surrounding the written voids forms a polycrystalline structure that is again reminiscent of the micro-crystalline structure of many common rocks.

The intent of the scientists and engineers who developed the M-DISC was to develop the modern, digital equivalent of engraving data, literally, in stone. The characteristics and features that enable a rock to survive for tens of thousands of years without a change were the inspiration behind the product. It isn’t by chance that the M-DISC data layer is similar to a rock — it’s by design!

Measuring M-DISC performance to directly determine the longevity is a challenge. When something changes very slowly, taking meaningful measurements requires a long time. The data layer is so resistant to oxidation that observable changes in an M-DISC stored under normal conditions are still very small after weeks or months. One way to deal with this challenge is to make a worst-case estimate of the lifetime using well-known theories and data, then test the results against measured data to see if the estimate is useful.

Theorists agree that the oxidation of metals like those used in the M-DISC proceeds logarithmically. The bare metal forms a very thin, nano-scale oxide layer very quickly. This oxide layer then protects the rest of the metal layer from further oxidation. The reflectivity over time is represented by the curve shown in the graph on the left. Most of the change in reflectivity would occur in the first few months after the DISC is manufactured.

A worst-case scenario for failure in the data layer would be a critical loss in reflectivity as the metals in the M-DISC slowly oxidized. Failure would occur when the reflectivity dropped below the minimum specification of 18%. The above graph shows the reflectivity curve we would expect to see due to oxidation if the M-DISC data layers reach a reflectivity of 18% after 10,000 years. The curve shows that if the M-DISC was readable for only 10,000 years, we would expect to see an M-DISC lose more than 3% reflectivity after aging only 50 days. A 3% change is easily measureable. Of course, if the reflectivity changed at a slower rate, the M-DISC could be expected to last even longer. The actual observed reflectivity change is less than 1% after 300 to 350 days (as shown with the graph above) indicating the actual performance of the M-DISC data layer is significantly better than our worst-case scenario. The comparison of the actual data to the 10,000-year example is very favorable. The obvious conclusion is the data on an M-DISC should be readable for greater than 10,000 years when stored in an ordinary, dry, room- temperature environment.

Since it is doubtful that the polycarbonate substrate materials can endure for that length of time, the substrate materials must be the actual weak link in the M-DISC structure. External studies conducted by the National Institute of Standards and Technology (NIST) concluded that the substrate materials in DVDs should be reliable for at least 1,000 years. Therefore, a lifetime estimate of at least 1,000 years, limited by the durability of the polycarbonate substrate, is very reasonable.

Where is the inaccuracy?

They already do. Don't worry about that.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.