Patterned media nanoholes

Posted on 04/20/2008 9:13:39 AM PDT by Ernest_at_the_Beach

Hard drives could experience a massive increase in capacity next year now that a "major" HDD maker has placed an order for equipment to mass-produce 'patterned media' drives.

Earlier this week, Malmö, Sweden-based fabrication-equipment maker Obducat announced it had reached an agreement with "a major player in th HDD industry" to supply the unnamed company with up to SKR66m ($11.13m) worth of lithography hardware.

Obducat will provide the mystery vendor with a "production-ready" Sindre lithography machine, used to create the high data-density surfaces used by the new drive technology. More equipment orders may follow, the Swedish firm said.

Fujitsu is a possible candidate for the HDD maker behind the Obducat deal - it has worked on patterned media technology since 2005. Canon was working on the technology in the early years of the decade and continues to do so, but it's not a major hard drive maker.

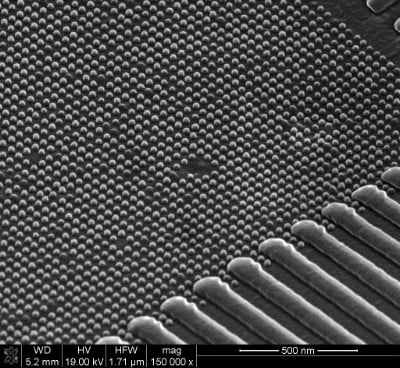

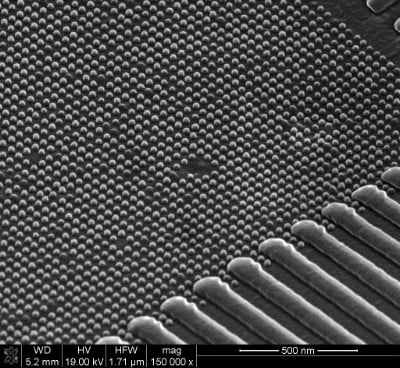

The technique involves establishing microscopic 'nanoholes' within a sheet of aluminium oxide. The holes form a pattern, hence the name.

Patterned media nanoholes

Each hole is filled with a magnetic material, each holding a single data bit. The surrounding oxide insulates each hole from its neighbours, preventing data corruption.

The holes are so small, they can only be created using the lithography techniques employed to make microprocessors and other chips.

Obducat claims its Sindre systems have been used to create holes as small at 17nm in diameter - not far short of the 13nm that Fujitsu last year reckoned was required to yield an areal density of 1TB per square inch.

That compares with the 65GB per square inch record claimed by Western Digital back in October 2007 - and even that's higher than the 25GB per square inch density of typical HDDs.

Obducat said its customer will take delivery of the first Sindre litho systems in "the first half of 2009". The machines are designed to work on 4, 6 or 8in wafers and, Obducat claims, can churn out discs at a rate of up to 30 per hour.

Yields are another matter, of course, but the company has the best part of a year to work on that, with further tweaking once its customer gets the systems in place. Another major challenge is getting the nanoholes into the precise order needed for read/write heads to access their contents efficiently.

Thanks to reader Patrik Stockselius for the tip ![]()

THANKS.

Much appreciate your knowledgeable answer.

Have pondered that for 20 years.

Nice to lay it to rest finally! LOL.

If you remember these, you’re old:

a) g c800:5

b) 820, 6, 17, 820, 65535

For bonus points, name the manufacturer and a product name of A & B (there were far more than just one)!

Mark

BTW, I’m not old, I’m ancient, practically prehistoric!

Guess I’m not old enough....But I am forced to draw down my IRA’s.

WD(R) Announces WD VelociRaptor(TM) - The World's Fastest SATA Hard Drive

Next-generation 10,000 RPM, 2.5-inch, 300 GB SATA Hard Drive,...but in a 3.5" Form Factor....not a notebook drive.

I don’t know if this will help but IBM 3380 DASD used multiple platers and arms. Each arm had 2 heads one for the top and one for the bottom of each platter. The heads “flew” above the surface. The air system had to come up before the platters were allowed to spin.

Admittedly they were not 3.5 “ platters and they were not trying to”seek” a TB of date in nanoseconds. I would suspect inertia, mass, etc. would be a challenge in the speeds and capacity of todays small drives.

That’s quite logical to this layman.

Thx.

a: Low level format. Seagate was one and so was Western digital. I might even still have one laying around.

b: I want to say an ST-251-1 but the cylinders seem wrong...

17 sectors, MFM?

Maybe one of those old Miniscribe bricks that went out?

Miniscribe bricks:

http://en.wikipedia.org/wiki/MiniScribe

I wonder how fast the masonry was for access?

Actually, it's been too long... Was it G c800:5, or g=c800:5? Either way, that was the debug code to fire up the ROM based disk formatting utility on the Seagate and Western Digital 8 and 16 bit MFM controllers. IIRC, the WD-1007 ESDI controllers used the same address, however, the WD-1006V RLL controllers used CC00:5.

And yes, the drive geometry for the Seagate 40 megabyte MFM drive (the Seagate ST-251. The difference between the 251-0 and 251-1 was 65ms vs 40ms access time - or was it 40 and 28ms? Either way, it no longer matters when a cheap video card has more than 3 times the RAM than these old hard drives, once considered by many to be more than you'd ever need on a server!). 820 cylinders, 6 heads, 17 sectors/track.

Another one I have memorized is the 40MB Mitsubishi MR535. 977x5x17, though it WAS certified to run as a 65MB RLL drive. And WOW! Did they run HOT!!!!!

Mark

Hitachi?

As long as yer breathin’, yer not too old!

(I told on myself, didn’t I?) LOL

I don’t know...There seems to be a lot of players...don’t think all of them are going to make it.

btw...and this is just a guess but I'll bet HDD is not Hillary Deficit Disorder?

a) No clue (not that uncommon)

b) Head/cyl/sect for a Seagate ST251

Amazing the things we learn on FR !!

You probably have something still running with an ST-225, hooked up to a WD RLL controller to get another 10MB out of it.

Are those new drives or drives that have been returned to Fry’s a dozen times?

: )

I can't seem to find the number ST310005N1A1AS-RK on the Seagate Website,...that number is the Seagate suppliedsticker with the serail number....

The Fry sticker has ST31000340AS...which is on the Web Site....

Seagate is probably just trying to get its warehouse cleaned out a bit .

The 500 Gig drive on the shelf had a sticker of 189$....

LOL....HDD is Lingo for Hard Disk Drive...which replaced DASD which stood for Direct Access Storage Device....

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.