Posted on 05/21/2022 9:03:12 PM PDT by algore

TOKYO, May 17, 2022 - Mitsubishi Electric Corporation (TOKYO: 6503) announced today that the company has developed an on-orbit additive-manufacturing technology that uses photosensitive resin and solar ultraviolet light for the 3D printing of satellite antennas in the vacuum of outer space.

The novel technology makes use of a newly developed liquid resin that was custom formulated for stability in vacuum. The resin enables structures to be fabricated in space using a low-power process that utilizes the sun's ultraviolet rays for photopolymerization.

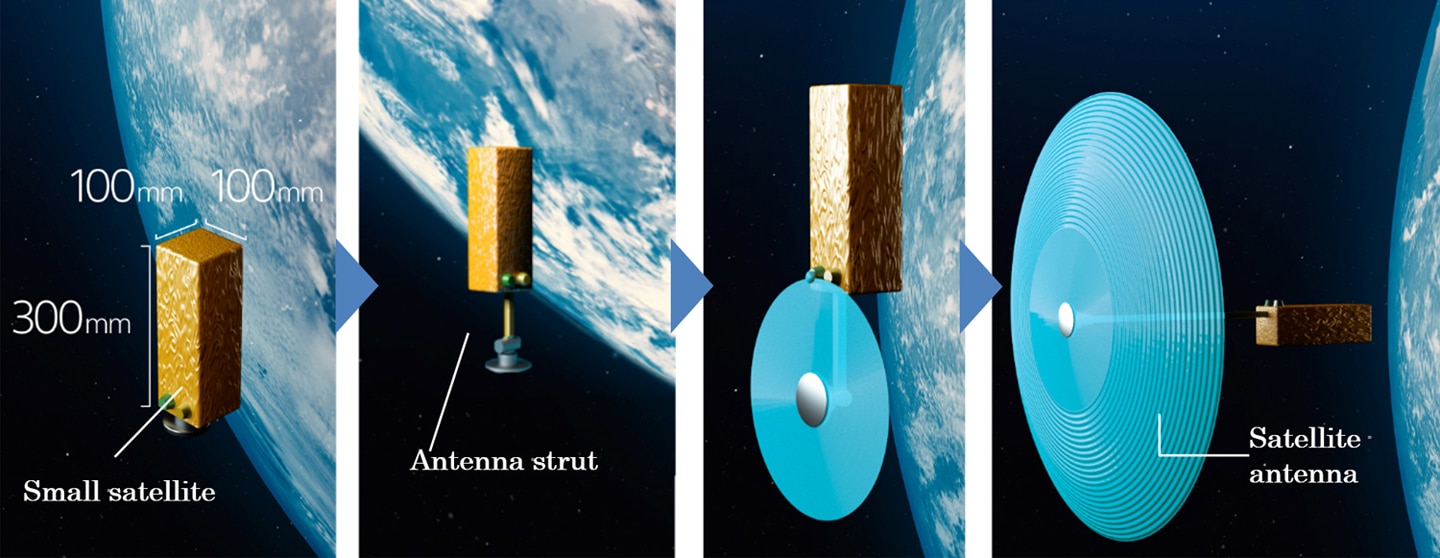

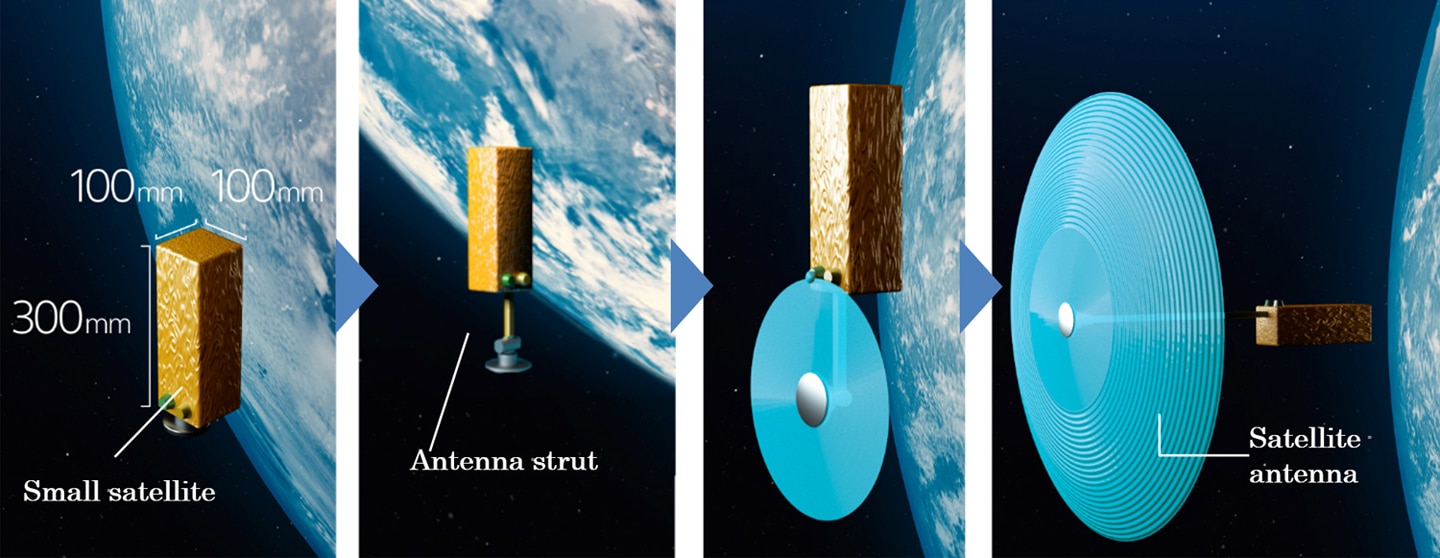

The technology specifically addresses the challenge of equipping small, inexpensive spacecraft buses with large structures, such as high-gain antenna reflectors, and enables on-orbit fabrication of structures that greatly exceed the dimensions of launch vehicle fairings.

Resin-based on-orbit manufacturing is expected to enable spacecraft structures to be made thinner and lighter than conventional designs, which must survive the stresses of launch and orbital insertion, thereby reducing both total satellite weight and launch costs.

Spacecraft antenna designs are challenging due to their conflicting requirements for high gain, wide bandwidth, and low weight. High gain and wide bandwidth necessarily require a large aperture, but economical orbital deployment conventionally dictates that designs be lightweight and small enough to fit or fold inside a launch vehicle or satellite deployment mechanism.

Mitsubishi Electric's innovative approach—resin-based on-orbit manufacturing—efficiently realizes high-gain, wide-bandwidth, large-aperture antennas deployed from a lightweight, vibration-resistant launch package. By developing a 3D printer that extrudes a custom ultraviolet-curable resin formulated for vacuum, resin-based low-power freeform* additive-manufacturing in space has now become possible

I would need to see that to really understand it.

I am familiar with the ‘printing’ capabilites of many home computers, but not for something as detailed as Satellite Antennas.

The simple reflector is what is being produced.

That is ingenious! Just haul raw materials to orbit, 3D print your antenna structure, and let solar UV do the curing. You can build structures larger than the rocket fairing.

How long before they can print solar cells for power generation. I worked for a company once that was able to print solar cells.

This has GOT to provide some good material for the plots

of some great science fiction horror-thriller movies, eh?

I’ve seen it in the research lab where I worked. It was first just a glorified ink-jet printer that used conducting ink to print the antennas on a substrate (e.g., for RFIDs) but there were also advanced projections of using 3D printers to do basically the same thing, but to make antenna structures...

What next?

Have you ever seen a liquid antenna? I worked on a design project with that once. [but versions of liquid antennas have been around in ham for a while - novelty]

Then, of course, there are fractal antennas but their use and ‘mystery’ have some issues.... :0)

Finally, the Unicorn - an small, ultra wideband high gain antenna.

So from those pics it looks like the extruder oozes the resin on a rotating base in ever expanding circles. The resin would have to be sticky enough to attach to the previous layer. Then the rotation would have to be slow enough for the last layer to have been cured before the next layer was applied. And if the resin had a metallic content it would work as a signal reflector.

Heating the resin to the sticky / extrudable point must take a lot of energy which is not exactly abundant on spacecraft.

You must be thinking of heating a filament into liquid and then extruding it. Resin printers start with a liquid photosensitive resin.

I could see a space station getting into manufacturing these things for satellites, then sending them on their way.

Current earthling 3D printing methods listed below. SLA and DLP use a liquid photosensitive resin. That is the material used in this.

https://3dinsider.com/3d-printer-types/

Stereolithography (SLA)

Digital Light Processing (DLP)

Fused deposition Modeling (FDM)

Selective Laser Sintering (SLS)

Selective Laser Melting (SLM)

Electronic Beam Melting (EBM)

Laminated Object Manufacturing (LOM)

Binder Jetting (BJ)

Material Jetting (MJ)

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.