All true, but it doesn't say that properly honing the cylinder makes the rings spin around the piston.

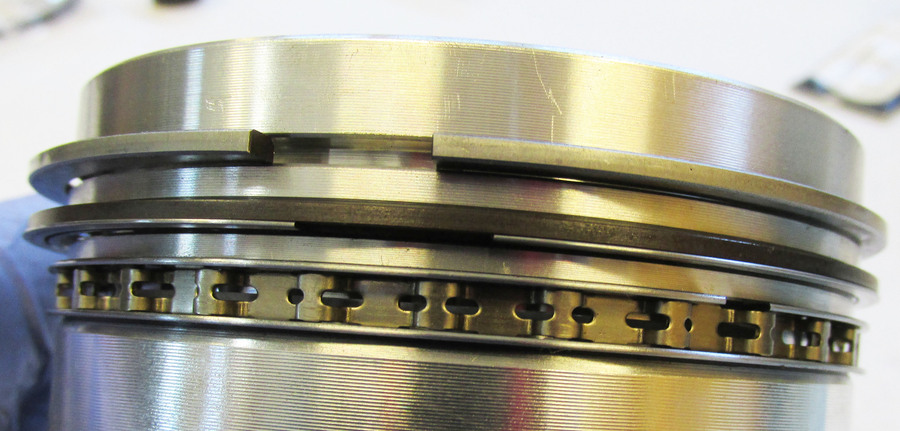

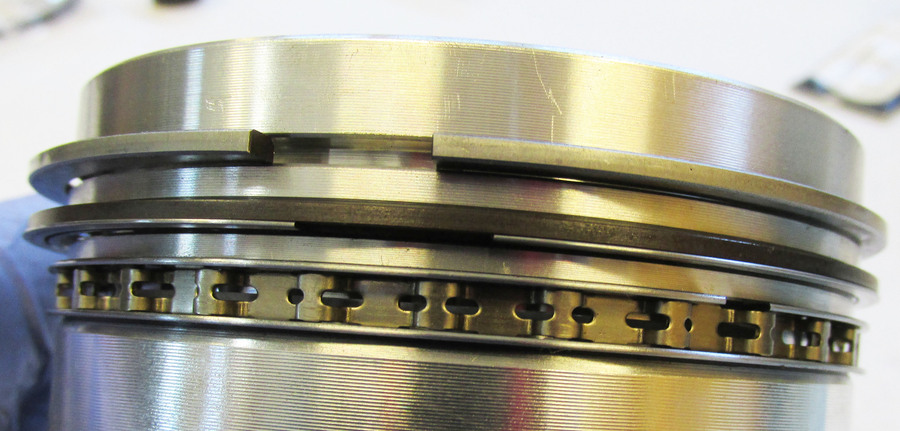

However, I wonder how those "gapless" rings manage to form a good compression or oil seal. To work properly, a regular piston ring has to constantly exert a certain amount of tension against the cylinder wall. They are built slightly larger than the cylinder bore, and are "compressed" into the cylinder leaving a gap - so you can measure how much tension is left to hold it tight against the cylinder wall after it wears. If it is a solid ring, it will begin to leak and pass oil/gasses once it breaks in the cylinder wall and has even the slightest amount of clearance.