Oil refining is done using a 'cat cracker,' or catalyst, to break up the long-chain hydrocarbons that make the heavy components of crude oil and create more of the shorter-chain compounds that make up gasoline. Building a homebrew catalysis reactor for refining petroleum is beyond the home hobbyist, unless you happen to be a chemical engineer with access to a lot of cool tools and materials.

However, you can burn the no. 2 oil straight up in a diesel engine. You can also burn kerosene straight up in a diesel, and if you pre-heat it to drive up the vapor pressure (wrap a few coils of copper fuel line around the exhaust manifold) you can burn kerosene in a low-compression gasoline engine. If you choose this latter option, count on re-jetting your carb (don't try this with a fuel-injected engine unless you can also reprogram the E-prom for kerosene). Also count on hard starting, reduced power, and ugly emissions. If I were going to try to run a car on kero, I would build it as a dual-fuel system that could start and run on gas until it was warmed up, then switch to kerosene.

My father in WWII was in Australia for several years, and Indochina and Phillipines. He told me in great detail (naval engineer style) about the Aussie buses powered during the war with wood gases. A critical element to the powering of the vehicle was the job of a local boy or aborigine-- to pick out of the "cooker box" the charcoal created by the cooked raw original wood pieces and transfer them by a little shovel into the burner heater below. They rigged up a little seat on the back outside of the bus (with a shade from the sun-- hot damn job) for the "stoker".

Here is the principle behind this setup-- far safer than trying to make gasoline!!: Charcoal burning conversion kits, which are really wood gas generators, enjoyed a brief civilian and military niche market in England, Germany, Australia, the United States, and other countries up to and during World War II. Wood gas generators were used to power taxis in Korea as late as 1970.

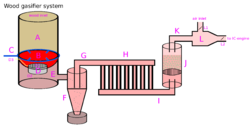

A charcoal burner actually burns the gases produced by heated wood. The burner is a two part system: a closed chamber with chunks of wood in it, and a charcoal burner to heat the closed chamber and make the wood generate gases by a process called pyrolysis.

Flammable gases produced by pyrolysis are then routed to a carburetor of sorts, mixed with air, and burned in the engine’s combustion chambers. Once the wood in the closed chamber has produced gases and turned to charcoal, it is transferred to the charcoal burner to heat the next load of wood. Some charcoal-fueled cars were designed to be started on gasoline, and would then be switched to charcoal once the vehicle was underway.

Flammable gases produced by pyrolysis are then routed to a carburetor of sorts, mixed with air, and burned in the engine’s combustion chambers. Once the wood in the closed chamber has produced gases and turned to charcoal, it is transferred to the charcoal burner to heat the next load of wood. Some charcoal-fueled cars were designed to be started on gasoline, and would then be switched to charcoal once the vehicle was underway.

Flammable gases produced by pyrolysis are then routed to a carburetor of sorts, mixed with air, and burned in the engine’s combustion chambers. Once the wood in the closed chamber has produced gases and turned to charcoal, it is transferred to the charcoal burner to heat the next load of wood. Some charcoal-fueled cars were designed to be started on gasoline, and would then be switched to charcoal once the vehicle was underway.

Flammable gases produced by pyrolysis are then routed to a carburetor of sorts, mixed with air, and burned in the engine’s combustion chambers. Once the wood in the closed chamber has produced gases and turned to charcoal, it is transferred to the charcoal burner to heat the next load of wood. Some charcoal-fueled cars were designed to be started on gasoline, and would then be switched to charcoal once the vehicle was underway.