*************EXCERPT******************

The “Dome”

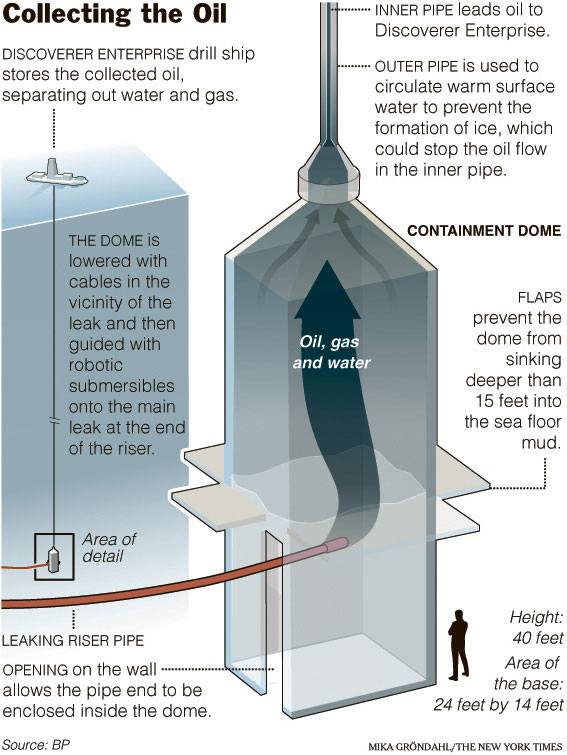

Let's talk about the dome a little. It would appear from the photos that the dome is designed to be large enough to encase the BOP. It has mud mats 16 feet off the bottom, so obviously the idea is to let it sink into the mud which will stabilize the dome and keep it in place.

****************************************************

Image from a recent New York Times article

The dome should act as a primary oil/water separator and minimize the amount of water going up the drill string. But even better, if I understand the plan correctly, the leak will probably be above the oil/water interface (water will not entirely fill the dome), which means if the dome system is working smoothly, the oil leaking from the riser will never come in contact with the water before it heads up the drill string.

The dome has to be open to the sea water near the bottom, so the pressure will equalize. If the dome were to seal tightly to the seabed, any negative pressure created by the oil rising in the drill string would suck the surrounding mud sea bed right up into the drill string (this is the principal behind suction anchors for drill rigs), and possibly collapse the containment vessel.

I assume the way they will control the system will to be to monitor the level of the oil/water interface inside the dome and throttle the flow at top of the drill string to keep the oil/water interface at a set level.

It is to be connected to the Discoverer Enterprise with a 6-7/8” drill string. Based on some rough estimates I made, if a person assumes the specific gravity of the oil is 0.89, the specific gravity of sea water is 1.026, the depth is 5,000 feet (actually this is of little importance in calculating the maximum flow), and a freeboard of 33 feet to reach the drill ship deck piping, it should be possible to get about 24,000 bpd on the ship using the natural buoyancy of the oil alone. Most of my numbers, especially the specific gravity of the oil, are conservative, so the maximum throughput could be greater, maybe much greater.

If the drill string is filled with oil, the static pressure is entirely dependent on the specific gravity of the oil and the actual water depth. Roughly, if the specific gravity is 0.80, then the pressure at the water surface would be about 500 psi; if the specific gravity of the oil is 0.90, the pressure would be just under 300 psi.

In real life any entrained gas will make a major difference. If the drill string was entirely filled with gas, the static pressure at the surface would be over 2,200 psi. And as soon as you start mixed flow, you get into undefined territory unless you know the exact percentage of gas mixed in the oil.

Entrained gas in the leaking oil will greatly change the flow dynamics, as the gas will expand approximately 150 times going up the drill string and act as a giant airlift. The problem then won’t be getting the oil up the drill string; it will be throttling back the flow onboard the drillship. Luckily, a deepwater drillship will have the proper equipment to handle this.

The expanding gas also has a substantial cooling effect, enough to freeze the water entrained in the stream. So the design of the drill string has been modified to include a warm water jacket and a methanol (antifreeze) injection system.

They have a potentially dangerous situation separating the oil, gas and water, but since the Discoverer Enterprise has processing equipment on board they should be able to handle that safely. The Enterprise also has dual draw works and drill floor, so they are equipped to handle a second drill string to another dome if needed.