Posted on 10/25/2016 11:20:52 AM PDT by 2ndDivisionVet

"[Three-dimensional] printing brings something to magnet design which we could previously only dream of," said researcher Dieter Süss.

VIENNA, Oct. 25 (UPI) -- From a technological perspective, making a powerful magnet is no problem. Precisely controlling the shape of magnet's magnetic field, however, has proven difficult -- until now.

Engineers at TU Wien have for the first time designed and produced magnets using a 3D printer.

The method offers scientists newfound control over the size and shape of the magnetic field, allowing them to produce magnets that better meet the needs of a range of technologies.

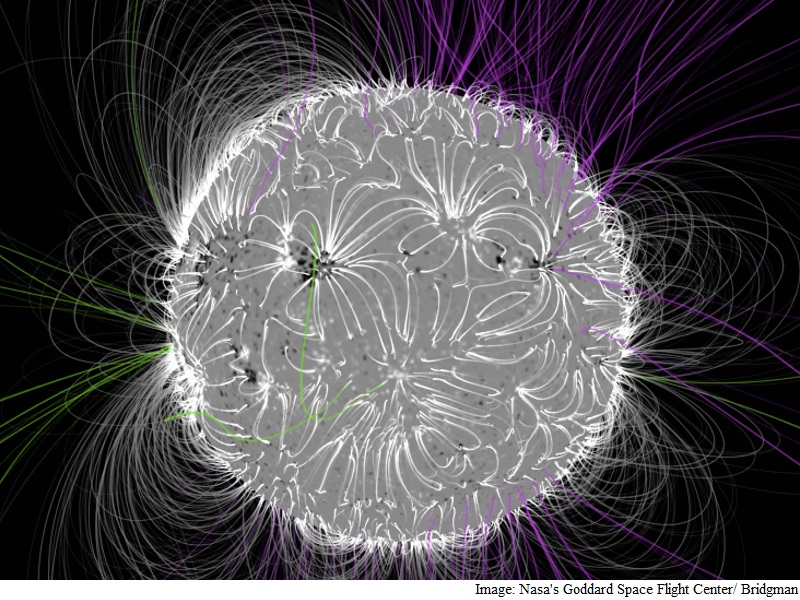

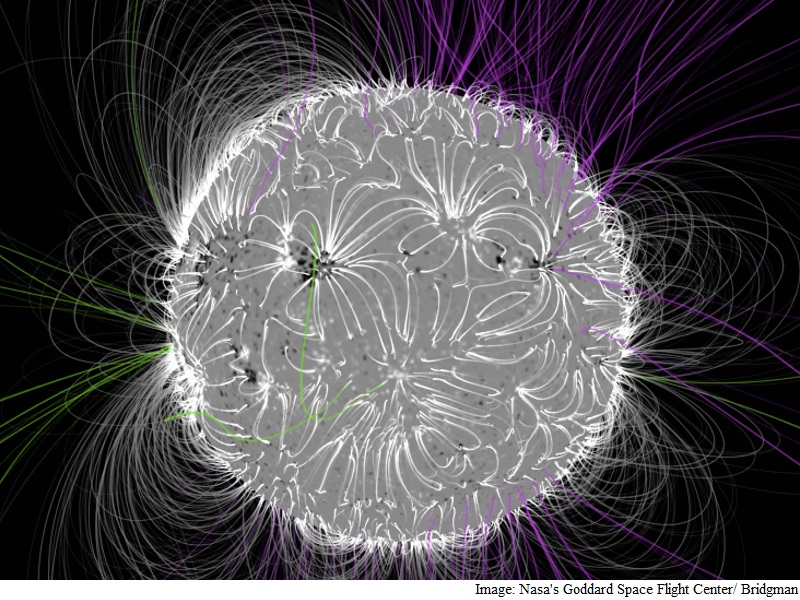

"The strength of a magnetic field is not the only factor," Dieter Süss, material scientist at TU Wien, said in a news release. "We often require special magnetic fields, with field lines arranged in a very specific way -- such as a magnetic field that is relatively constant in one direction, but which varies in strength in another direction."

Scientists have had the know-how to design the ideal structural patterns for specific magnetic circumstances, but that knowledge has been mostly relegated to the computer. Traditional injection-mold technology is too expensive and time consuming to make the translation of the digital science worthwhile.

That's not the case with 3D printers, which are fast, cost-effective and ideal for small-batch production.

The 3D printer uses magnetic micro granulate to create intricately designed geometric patterns. The granulate structures are bound together by a special polymer. The printed product isn't actually magnetic fresh out of the machine. The granulate is printed in an unmagnetized state. But when the printed object is exposed to a strong magnetic field, the granulate takes on its intended magnetism.

"This method allows us to process various magnetic materials, such as the exceptionally strong neodymium iron boron magnets," explained Süss. "Magnet designs created using a computer can now be quickly and precisely implemented -- at a size ranging from just a few centimeters through to decimeters, with an accuracy of well under a single millimeter."

Researchers say their findings -- detailed in the journal Applied Physics Letters -- will not only improve current technologies, but empower new ones.

"Now we will test the limits of how far we can go -- but for now it is certain that 3D printing brings something to magnet design which we could previously only dream of," Süss concluded.

I find this product attractive.

Engineers did. The scientists are camped up in the Arctic measuring fossilized sea ice whale poop, which contains trace amount of industrial era carbon footprint.

Can they print a sphere with all the N poles facing out and all the south poles facing inward, BAM instant mono-pole...

cool

Nano-motors! Tiny magnets will allow building of powerful nano-motors in nano size objects. Picture tiny motorized craft with cutting tools making their way through the human body, striking a blow against tumors and such. Hmmn, there have been some sci-fi movies on the subject!

People sometimes ask me when I post 3D Printer threads “Yeah, but what practical purpose do they serve?” Here’s an example.

We havent even begun dreaming up the uses for this tech. Could be even bigger than regular-ole 3D printing.

I think 3-d printers are amazing...people really give you a razzing for posting the threads?

A few. People give me a “razzing” for almost every subject I broach. LOL

“People give me a “razzing” for almost every subject I broach.”

I’ve noticed that myself, but, like a good soldier, you keep marching on :-). Many of us appreciate it too :-)! Keep up the good work!

Thank you.

3d printing amazes me as well and I have learned a good bit here. Thanks 2nd.

That would still be a dipole magnet, just in a different arrangement.

I’m really excited about all the accelerated science breakthroughs in soo many areas. If it weren’t for the horribly regressive political environment, I’d be very hopeful for our future. Instead, I wonder if we really are headed towards something akin to a Blade Runner future. Hope not!

Uh oh just when you thought microphone technology had matured.

They serve practical purposes for my workshop. I have printed knobs for my drill-press and router table. I tried gluing on other knobs to my drill-press height-adjustment spinner with poor results. Then I designed and printed knurled ABS knobs, heated up the drill-press threaded steel robs with a torch and pushed on the ABS knobs and let them cool into place. They work perfectly. Same for hold-down knobs for attachments on my router table. I made custom wall-hanger brackets for tools, such as hanging bars with holes to hold all my files within reach. Custom clamps to secure multi-outlet extension bars under cabinets. Custom feet under equipment. And so on. Inside the home, I made custom tripod quick-release clamps for my camera gear, something I could not buy anywhere. Then there are electronic purposes. I made custom cabinets for small keyfob remote controls, housing for custom LED light strips and brackets to illuminate my 3D printer printheads and platform, a cabinet for a Pine64 micro-motherboard computer. And other things.

Lots of practical purposes for 3D printers in the home, that you can design yourself. Then there are the downloadables that other people created - thousands of them.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.