Japan slices the pigs into useable discs.

SKorea etches and parts the finished sizes.

China does the wiring and connectors and

Taiwan does the finish assembly.

Due to the fuel embargo in 1973, my father's overtime was cut as a tool and die maker. So he responded to an ad in the newspaper that was looking for a machinist. He accepted the position and started to work evenings after a full day at his primary job. He was the first employee hired by the new company, Specialty Metals and Alloy in Grove City, Ohio (a suburb of Columbus). Neil Grisenhower (PhD Chemical Engineering) and Leo Winzinger (Engineer) were former employees of Battelle Memorial Institute near the campus of The Ohio State University where they helped developed sputtering technology.

They saw a building market in high pure metals and alloys needed for the new sputtering technology used in thin film processing. This ranged from course applications such as chrome-plated trim parts for the auto industry and reflective windows to extreme fine applications like integrated circuits. My dad even made the prototype target used in the coating of Gillette's new Platinum Plus shaving blades - A mixture of Platinum and Chromium that would not alloy, but the ionic particles mixed in the appropriate mixture through the spacing of the slots and keys made by dad. One night he pulled out from our closet a rag-covered piece of metal - A platinum plate: 12 inches by 12 inches and a quarter inch thick with 45-degree angled slots cut with chromium keys inside the slots and spaced at the distance to provide the desired mixture. He had to bring it home during the night because he did not know the combination for the safe. Dad said that one part had about $100,000 invested in the metal and that was in the mid-1970s. A lot of the added expense was in the 5 nines purity, meaning 99.999+% pure.

Dad retired from his full-time job and joined the company as a full-time employee until he retired in 1994. The company grew and during the 1970s and 80s enjoyed about a 95% market share worldwide in providing targets used in sputtering applications.

They divested themselves of the course application market to focus on thin film processing used in the chip-manufactured technology. The wafers mentioned above are cut from a 6 or 8-inch cylinder of highly pure alloys. Varian has the world's largest continuous melt furnace that allows the continuous extrusion of the high-pure cylinders without having to break vacuum - a huge technological development that eliminates the need to open the chamber to remove the crucible then restart the long-running task of drawing a new extremely fine vacuum.

Grisenhower and Winzinger eventually sold the privately-held company to Varian Electronics - one of the leading manufacturers of sputtering devices, then years later, it was sold again to the current owner, Tosoh Chemical.

Though not as dominant worldwide as they enjoyed years ago, they are still one of the leading providers of the targets used in thin-film applications.

One of dad's final projects was for the manufacturing process used for the targets used in the fairly new market (for the mid-1990s) for flat-screen televisions, then soon afterward, laptop screens.

Their technology provided the processes that replaced chip manufacturing based upon gaseous diffusion lithography to the atom's thick ionic spray of thin films needed for x-ray resolutions used for today's chips.

Here are some photos of the targets (aka cathodes) data helped pioneer.

The two targets that look like gold are likely 6 nines pure devices - meaning 99.9999+ purge gold. The final preparation of these devices before shipping includes a clean-room environment and x-rays to check for faults or microscopic cracks.

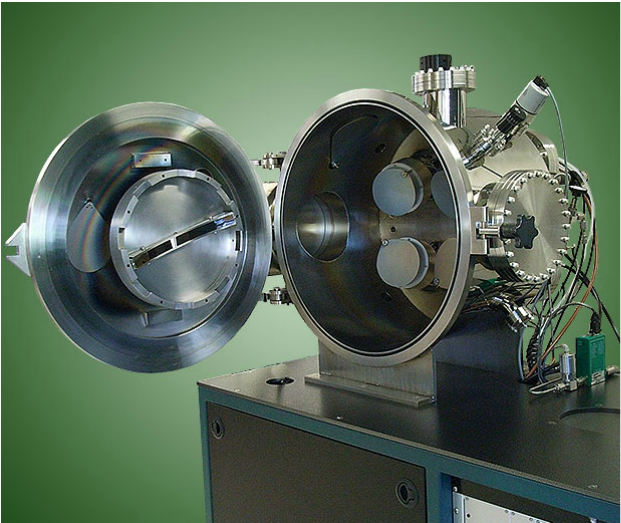

Here is an open chamber with two targets inside that will be used to coat one or more wafers.

Thanks for letting me brag a bit about my father :)