..and we all can go to the weekly Carrousel for entertainment!

..and we all can go to the weekly Carrousel for entertainment!

Just set up terrestrial gps on a site and let the drone do that stuff.

It will be more accurate and reduce man hours.

We already have machines manufacturing a good portion of homes and buildings off site and then we slap that stuff together in no time flat.

Pouring floors on site doesn’t really makes sense anymore.

Nor does slapping walls together.

Just do that at some central factory and run the infrastructure for wiring, outlets, plumbing, etc at the factory and then hime run that stuff to IDF’s and risers, where it can all be joined to feed back to MDF’s, roofs and basements.

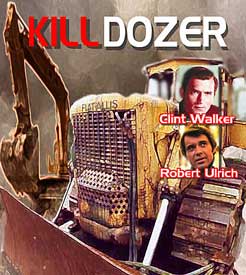

oh the horror movies I could write....

Good luck with that. There’s a lot more to equipment operation than plugging in GPS coordinates. You might think we are just a bunch of dumb dozer jocks but I assure you that’s not the case. Finish road grading by Trimble is already taking place. Mass excavating in varying conditions, good luck.

The trend has been bigger and bigger equipment, to reduce the amount of operator need per horsepower. With automation, the equipment will get small again, and you’ll have a half dozen little dozers speeding around digging holes. Between the mexicans and the robots, “operators” will be history.

Crane operators, often at the top of the pay scale, will also be out of work. The new cranes will be “fly by wire”. The mexican operator will suggest something to the crane, and the crane will do what it can, safely.