Posted on 04/20/2014 5:52:49 AM PDT by RoosterRedux

3D printers are building some pretty amazing stuff lately: working speakers, wooden furniture, prosthetic limbs, and even foods like pizza and pasta — but WinSun Decoration Design Engineering Co. of Shanghai, China is thinking much, much bigger.

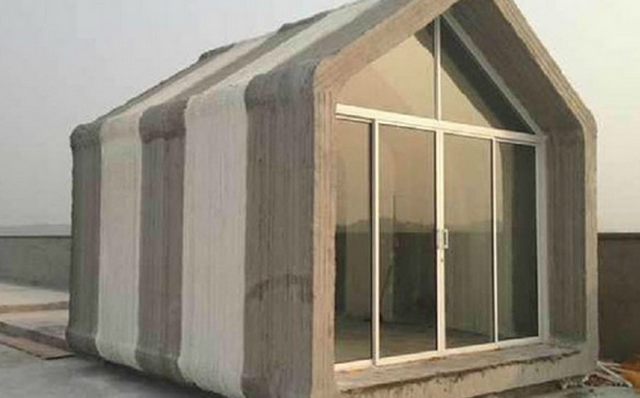

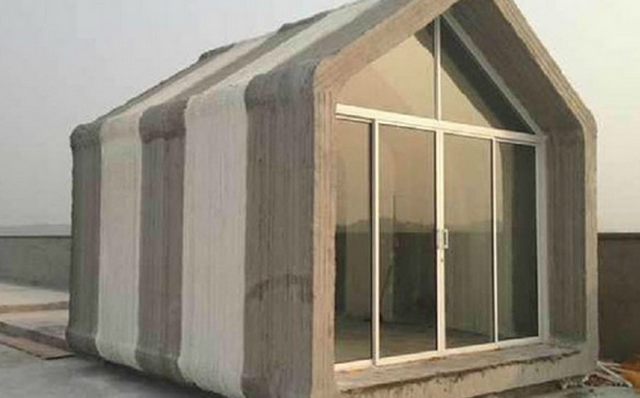

Instead of pumping out small plastic parts with a desktop-sized printer, these guys print out prefabricated living structures out of concrete using a massive, building-sized 3D printing machine.

Now, to be sure, 3D printing houses isn’t a particularly new thing. Companies have embraced the idea of additive manufacturing since before the term “3D printing” had even entered the popular vernacular. For this reason, it’s not the houses that WinSun creates that are impressive — it’s the blistering pace at which it creates them. Running at full speed, the company’s printer is capable of producing up to ten 650 sq. foot homes in just 24 hours.

(Excerpt) Read more at digitaltrends.com ...

I dunno if this would actually be any more useful, or faster, than simply using slip forms.

You don’t want to be in a concrete home during an earthquake.

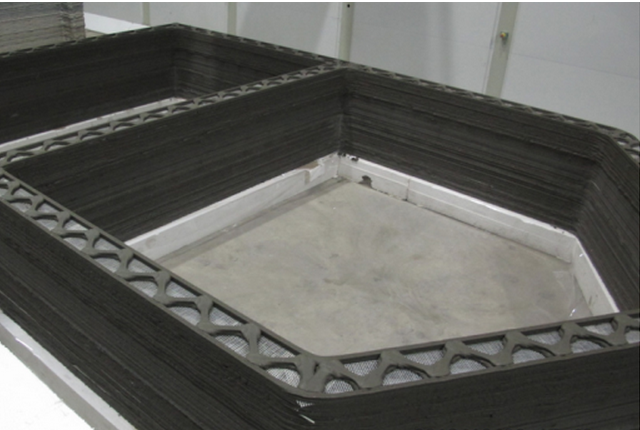

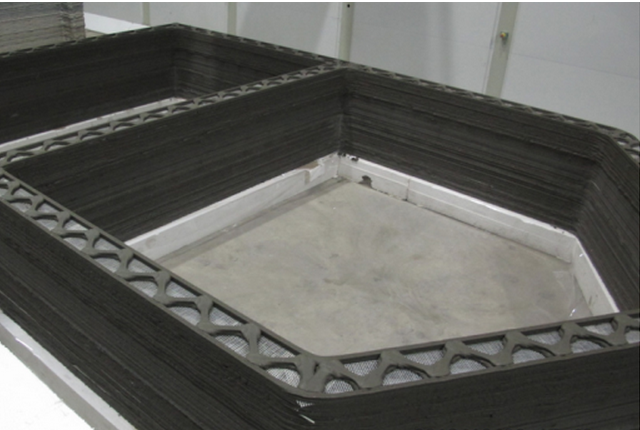

Exactly, no signs of rebar

The Chinese love concrete because they don’t have trees: burned centuries ago for heat.

Still, for a prototype, this is amazing.

Does it “print” glass windows too? Or is “building homes” just a lot of hype?

Anyone remember the “housing of the future” at the World’s Fair in Montreal back in ~’67? Little cubes of concrete stacked on one another. Super ugly. I forget what inviting name they called it.

Rebar would be sort of hard to 3-D copy.

I wonder if they throw something like fiberglass into the mix.

probably use the fiber impregnated concrete which would eliminate the need for rebar

Seriously. You can’t compare fiberglass to steel. Steel bends. Glass breaks.

Guess the question really is what is in the recycled materials.

snip

‘The best part is that, since the concrete is made from recycled materials,’

Read more: http://www.digitaltrends.com/home/giant-3d-printer-can-build-10-prefab-homes-24-hours/#ixzz2zR0najXb

Follow us: @digitaltrends on Twitter | digitaltrendsftw on Facebook

Fiberglass bends to some degree then it breaks. They’ve been mixing fiberglass strands with concrete for years eliminating rebar in many cases.

Made in China. Chances of getting a serious environmental ailment while living in the house: 100%. Plus concrete has very little thermal insulation.

It’s a good start, but there are some things to be addressed.

It hasn’t caught on in Haiti yet, of course neither has rebar.

I don’t think they bother much with windows there, nothing outside to look at.

Does anything?

Lots of potential in dealing with a natural disaster where housing is destroyed and livable space can be put up quickly...

A couple of thousand in a very short time...

Ten machines can print 1,000 homes a week...

The company I work that builds FEMA 361 Safe Rooms. Since we are in a serious seismic zone (New Madrid) the seismic reactions overrule the tornadic reactions. They are all built with prestressed concrete.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.