This is misdirection and half truth.

Note that the population if 1977 was about 220 million compared to the population today of 324 million.

That is a population increase of 47%.

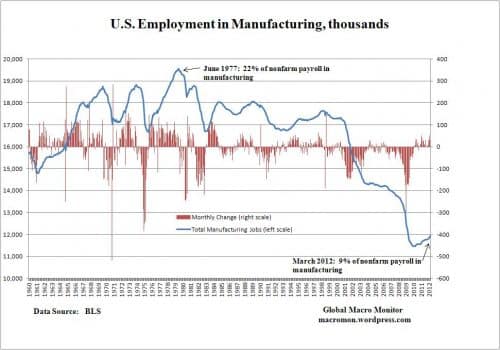

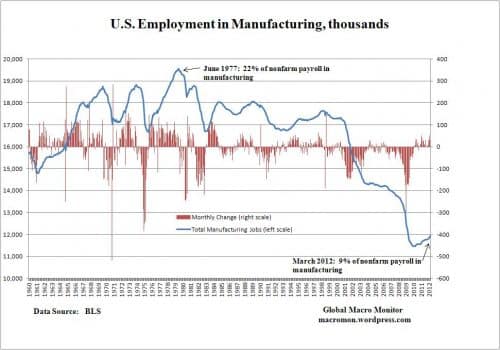

As shown in this chart, manufacturing jobs in 1977, comprised about 22 percent of all nonfarm payrolls.

But manufacturing jobs today only comprise 9% of nonfarm payrolls.

That is only 40% of the 1977 level.

So not only has the population gone up by 124 million, the percentage of the working population engaged in manufacturing is less than half of the 1977 level.

Certainly automation plays a major role, but all of those cars, trucks, tractors, electronic devices, appliances and garments coming here across borders and oceans didn't manufacture themselves in totally automatic factories.

That is only 40% of the 1977 level. Manufacturing employment is way down, having peaked just before 1980, despite a rising population, as you point out. However, manufacturing output is way up. A similar phenomenon has occurred in agriculture — employment way, way down, output way, way up. In both cases, we are seeing the effect of automation.

Certainly automation plays a major role, but all of those cars, trucks, tractors, electronic devices, appliances and garments coming here across borders and oceans didn't manufacture themselves in totally automatic factories.

Here is a Tesla factory. The workers are all dressed in red and black, including the human (hint: he is about where Ohio would be on a US map):

In China, automation is coming on strong, as wages rise. Example:

Dongguan — a city near Hong Kong that’s basically the manufacturing capital of the world — recently launched their first automated factory. The Changying Precision Technology Company manufactures parts for mobile phones. It has 60 robot arms that work on 10 production lines that run 24 hours a day, 7 days a week. Each production line has 3 human workers who monitor the robots.

Before these new robots arrived, the factory needed 650 human workers to be able to operate. Now it just needs 30.

Since this factory laid off 95% of its workers, and handed over the task of manufacturing to the machines, its defect rate has dropped by 400%, and its overall output has nearly tripled.

More production, fewer people.