Exactly.

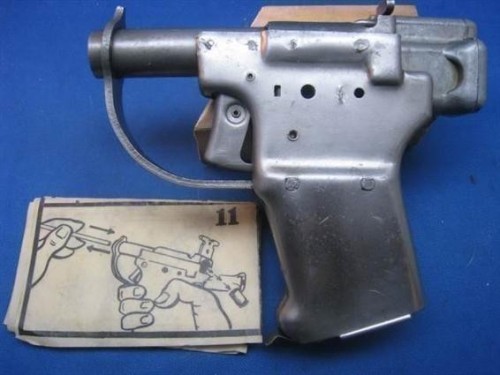

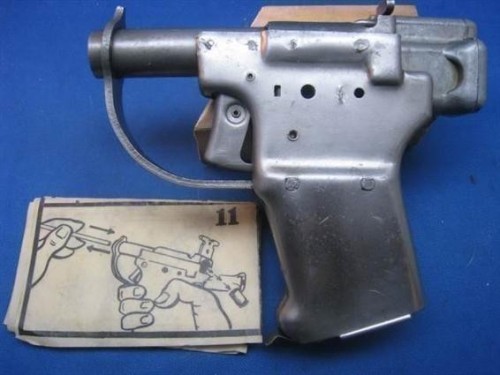

People don’t seem to realize that guns are EASY TO MAKE. Really. They are.

The reason why so many people don’t realize this is that we’ve extirpated machine shop and practical mechanical classes from high schools so that we could make room for all manner of useless gibberish for the college-bound nitwits who don’t (and won’t ever) know their asses from a warm rock.

The only part on a gun that I can’t make and couldn’t teach you how to make easily in your own garage is the barrel. I take that back: I could teach you how to make a barrel, but it wouldn’t be an accurate barrel. And it would be much easier to teach people how to make pistol barrels in larger calibers, like a barrel for a .45, for example. Making small broaches and rifling buttons is harder than making big ones.

The rest of a serviceable firearm (especially a semi-auto pistol using a blowback design) I could teach anyone but the most inept tool-killing klutzes how to make in their garage.

Now, everyone has a major jones for AR’s just now. AR’s have a couple of interesting details that make them difficult (for the uninitiated) in how to deal with the inside voids like the magazine well.

Well, that’s no big deal. All you need to do is section an AR lower receiver lengthwise down the middle and cast the receiver in two halves - but leave on some bosses and alignment pins/holes to help you get the two halves together. Now you have a very simple issue to cast or make from aluminum bar stock on a mini-mill that could could buy at Horror Freights for under $1K. Add in another $500 in tooling and you’re in the business of making serviceable AR receivers.

Working in aluminum is PUD easy. Easy, easy, easy. It’s soft, it’s ductile, the most popular alloys (6061 and so on) are easily welded with oxy-acetylene or TIG (or even MIG) rigs, there are plenty of modern glues you can use to make snug-fit parts permanent joins, etc.

The roll pins for an AR can be had by the truckload from outfits like Fastenal.

The holes for the .154 pins are drilled undersized and reamed (with a straight chucking reamer) to size. The rear buffer tube mounting point is easily done if you align it in the mill vise and use a tap (which you can also buy from Fastenal as well as a dozen other tool companies) to cut those threads. Want to make a buffer tube? Another piece of aluminum and a die for threads. Oh, and you’ll need to fill the far end of the tube with a disc. More threading - just use green Loctite to glue the plug in the tube.

Springs? Easy. Wind piano wire around a form.

See where I’m going with this? THIS STUFF IS NOT ROCKET SCIENCE. I should know. I was force-fed orbital mechanics in my sophomore year in engineering school, so I know what rocket science looks like. This ain’t it. WTF a bunch of EE’s needed to be force-fed orbital mechanics for, I have no friggin’ clue, but we had to a) buy some hoity-toity idiotic book from the UK (with a powder-puff pink cover, no less) for this course, and b) this book could not be sold back to the bookstore for any amount of money, so I still have the wretched thing. Net:net, I can tell you that it takes a three stage rocket to reach the moon. Not two. Not four. Three. Two or four stages will simply not work.

Making a rifle like a Garand or M14 would be much more difficult. Much, much more difficult. Making an AR? Pfah. This weapon is one step up from making an AK from a poop shovel. The only things on an AR that would be actually difficult to make are a) the bolt and b) the bolt carrier. The barrel extension would be a bit difficult to make, but with some instruction in how to make a broach, it can be done.

Making functional weapons does not require a 3D printer. It does, however, require that some people learn how to work in metal, learn how to weld, learn how to operate a drill press and drive a file (or rather, a bunch of files). If you can drive a file, you can make a gun.

3D printers just make politicians wet their silk panties - because the liberal arts majors in the press and in political office can see how THEY could print out a gun. 3D printing makes things so easy that even some idiot in office in DC could make a gun. THAT scares them... but for real men, who know how to use real tools... guns are easy to make.