Click here: to donate by Credit Card

Or here: to donate by PayPal

Or by mail to: Free Republic, LLC - PO Box 9771 - Fresno, CA 93794

Thank you very much and God bless you.

Posted on 11/23/2025 11:02:01 AM PST by UMCRevMom@aol.com

|

Click here: to donate by Credit Card Or here: to donate by PayPal Or by mail to: Free Republic, LLC - PO Box 9771 - Fresno, CA 93794 Thank you very much and God bless you. |

ARTICLES

1. 6 Best Rare Earth Mining Companies in the USA Ranked for 2025

March 31, 2025/ UPDATED 15 JULY 2025

https://rareearthexchanges.com/best-rare-earth-mining-companies-in-the-usa/

Did you know that the USA depends on China for about 70% of its rare earth imports?

That’s right! Even though the U.S. has rich deposits of these critical minerals, only a handful of companies are extracting and refining them at scale. As global demand for rare earth elements (REEs) skyrockets—thanks to electric vehicles, renewable energy, and defense applications—investors and industry experts are hunting for the best American mining companies to bet on.

We’ll rank the top 6 rare earth mining companies in the USA, covering their operations, financial performance, sustainability efforts, and market potential. This ranking aligns with our Project/Deposit Database.

Let’s dig in.

WHATS’S INSIDE

What Are the Best Rare Earth Mining Companies in the USA?

1. MP Materials (NYSE: MP) – The Leading U.S. Rare Earth Producer

2. American Rare Earths (ASX: ARR) – Advancing Exploration Across the U.S. Southwest

3. USA Rare Earth – Developing Domestic Rare Earth Refining Capabilities

Expansion and Technology

4. NioCorp Developments (NASDAQ: NB) – Unlocking Critical Minerals in the Heartland

Long-Term Potential

5. Ucore Rare Metals (TSXV: UCU, OTCQX: UURAF) – Advancing Rare Earth Refining Technologies

Technological Innovation

6. Idaho Strategic Resources (NYSE: IDR) – A Growing Player in Domestic Rare Earth Exploration

Additional Notable Rare Earth Mining Companies

American Resources Corporation (NASDAQ: AREC)

Rare Element Resources Ltd. (OTCQB: REEMF)

Energy Fuels Inc. (NYSE: UUUU)

Texas Mineral Resources Corp. (OTCQB: TMRC)

Conclusion

FAQs

______________________________________________________

What Are the Best Rare Earth Mining Companies in the USA?

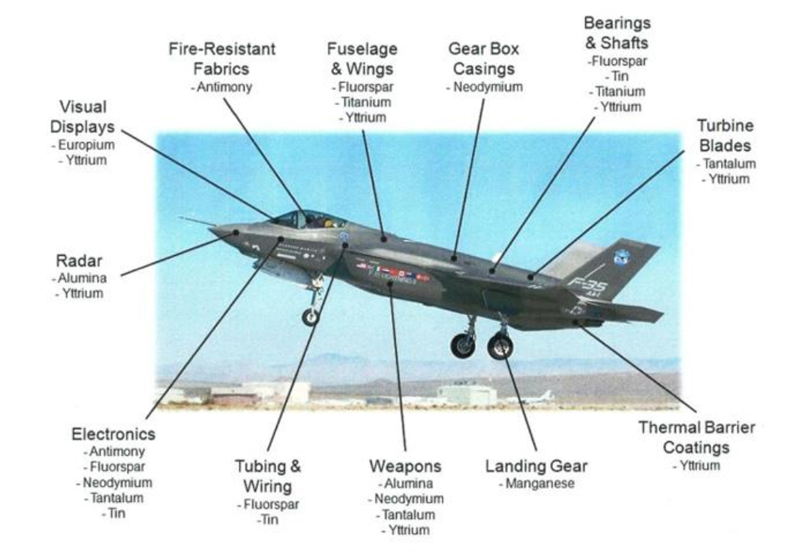

Rare earth elements are critical to modern technology, powering everything from smartphones to military equipment. The United States is working hard to develop domestic mining capabilities to reduce reliance on foreign suppliers, particularly China.

1. MP Materials (NYSE: MP) – The Leading U.S. Rare Earth Producer

MP Materials stands at the forefront of domestic rare earth production. Located in Las Vegas, Nevada, the company operates the Mountain Pass Mine in California – currently the only active rare earth mine in the United States. This strategic facility extracts crucial elements like neodymium and praseodymium, which are essential for high-tech industries and renewable energy technologies.

Financial Performance and Market Position

The company has shown impressive growth since its founding in 2017. MP Materials has consistently demonstrated strong financial performance, with increasing revenue and a robust stock valuation. Their Mountain Pass facility represents a critical asset in the domestic rare earth supply chain, attracting significant investor and government interest.

FUTURE OUTLOOK AND SUSTAINABILITY

MP Materials isn’t just focused on extraction. The company has ambitious expansion plans, including developing advanced refining capabilities and establishing strategic partnerships with government agencies. Their commitment to environmental sustainability and regulatory compliance sets them apart in the mining industry.

2. Domestic Rare Earth Refining in America: 7 Key Insights

March 14, 2025

https://rareearthexchanges.com/domestic-rare-earth-refining-in-america/

Did you know that over 85% of the world’s rare earth refining capacity is controlled by China?

That’s right—while the U.S. is rich in rare earth elements (REEs), it lacks the refining infrastructure to process them at scale. As global demand for rare earth materials surges due to their use in electric vehicles, wind turbines, and military equipment, America’s reliance on foreign refining is becoming a critical economic and national security issue.

WHAT’S INSIDE

Why Is Domestic Rare Earth Refining in America So Important?

The Current State of Rare Earth Refining in the U.S.

Key Challenges Facing U.S. Rare Earth Refining

Government Policies Supporting Domestic Refining Efforts

Key Players in the U.S. Rare Earth Refining Industry

Future Outlook: Can America Achieve Rare Earth Refining Independence?

Conclusion

FAQs

Why Is Domestic Rare Earth Refining in America So Important?

These crucial minerals power everything from smartphones and electric vehicles to advanced military equipment. Yet, the United States finds itself in a precarious position, heavily dependent on China for rare earth processing and refinement.

THE STRATEGIC IMPORTANCE OF RARE EARTHS

The national security implications are significant. China currently dominates over 80% of global rare earth refining, giving them immense geopolitical leverage. This concentration of supply creates substantial risks for U.S. technological and military capabilities. If China were to restrict exports, countless American industries could face immediate and severe disruptions.

ECONOMIC POTENTIAL OF DOMESTIC

Building a robust domestic rare earth refining industry isn’t just about security—it’s an enormous economic opportunity. By developing local processing capabilities, the U.S. could create thousands of high-skilled jobs, stimulate technological innovation, and reduce reliance on foreign suppliers. The potential economic impact extends far beyond the mining and refining sectors.

THE CURRENT STATE OF RARE EARTH REFINING IN THE U.S.

The domestic rare earth landscape is slowly evolving. Currently, the United States has limited refining capacity, with only a few operational facilities capable of processing these critical minerals. MP Materials (opens in a new tab) in California’s Mountain Pass mine represents one of the most significant domestic operations, extracting rare earth concentrates.

EMERGING INFRASTRUCTURE

Recent government investments and private sector initiatives are beginning to change the landscape. Companies like Energy Fuels are developing separation technologies, while strategic partnerships are emerging to boost domestic processing capabilities. However, the U.S. still lags significantly behind global leaders like China and Australia in comprehensive rare earth refining.

KEY CHALLENGES FACING U.S. RARE EARTH REFINING

Establishing a competitive rare earth refining industry is no small feat. The initial investment required is enormous, with infrastructure and processing facilities costing hundreds of millions of dollars. Environmental regulations add another layer of complexity, demanding sustainable practices that balance industrial growth with ecological preservation.

TECHNICAL AND ECONOMIC HURDLES

The skills gap presents another substantial challenge. Rare earth processing requires specialized knowledge and expertise that is currently limited in the United States. Moreover, competing with China’s established low-cost production model means American companies must innovate continuously to remain economically viable.

Government Policies Supporting Domestic Refining Efforts

The U.S. government has recognized the strategic importance of rare earth independence. The Defense Production Act (opens in a new tab) and recent infrastructure legislation provide critical funding and support for domestic mineral processing projects. Tax credits and investment incentives are helping to attract private sector investment into this crucial industry.

See also 5 Critical Challenges in US Rare Earth Supply Chains Explained

STRATEGICS INVESTMENTS

The Bipartisan Infrastructure Law (opens in a new tab) has allocated significant funds specifically for developing critical mineral supply chains. These investments aim to reduce dependence on foreign suppliers and build a more resilient domestic manufacturing ecosystem.

KEY PLAYERS IN THE U.S. RARE EARTH REFINING INDUSTRY

Several companies are leading the charge in domestic rare earth processing. MP Materials remains the most prominent, operating North America’s only active rare earth mining and partial processing facility. Lynas Rare Earths (opens in a new tab), an Australian company, has also established U.S. processing operations, indicating growing international interest.

EMERGING INNOVATORS

Smaller startups and technology companies are exploring innovative separation and processing techniques. Energy Fuels, for instance, is developing novel approaches to extracting rare earth elements from existing industrial waste streams.

FUTURE OUTLOOK: CAN AMERICA ACHIEVE RARE EARTH REFINING INDEPENDENCE?

The path to rare earth refining independence is challenging but not impossible. Technological advancements, increased government support, and growing private sector investment are creating a more optimistic landscape.

STRATEGIC COLLABORATIONS

International partnerships could accelerate development, particularly with allies like India and Australia. These collaborations could help share technological expertise, reduce investment risks, and create more resilient supply chains.

Projections suggest that the United States could significantly reduce its dependence on Chinese rare earth processing within the next decade. Success will require continued investment, technological innovation, and a commitment to building a comprehensive domestic rare earth ecosystem.

CONCLUSION

The U.S. is making steady progress in developing a domestic rare earth refining industry, but significant challenges remain. With government policies driving investment, private companies stepping up, and technological advancements on the horizon, America has a real opportunity to reduce dependence on China and establish itself as a major player in rare earth refining.

FAQs

What are rare earth elements, and why are they important?

Rare earth elements (REEs) are a group of 17 chemically similar metals essential for electronics, renewable energy, defense systems, and more. They are crucial for manufacturing high-tech products such as smartphones, electric vehicle batteries, and wind turbines.

Why does China dominate rare earth refining?

China has heavily invested in rare earth refining for decades, developing cost-efficient infrastructure and controlling a vast portion of the global supply chain. Less strict environmental regulations and government subsidies have helped China become the dominant player in this field.

How can the U.S. increase its refining capacity?

The U.S. can boost domestic refining by investing in new facilities, securing funding through government incentives, and fostering partnerships between private companies and federal agencies. Research into more efficient and sustainable refining methods is also critical.

What are the environmental concerns associated with rare earth refining?

Rare earth refining produces toxic waste and radioactive byproducts, making environmental management a major challenge. Sustainable practices, stricter regulations, and advances in refining technology can help minimize environmental impact.

Are there any U.S. companies currently refining rare earths?

Yes, MP Materials, Energy Fuels, and Lynas Rare Earths’ U.S. operations are among the key players working to expand domestic refining capacity. Several emerging companies and startups are also contributing to this effort.

2.

Interesting, but are you swimming in the deep end of the AI pool?

“are you swimming in the deep end of the AI pool?’

Check our the source articles

Now if I only played the stock market.... LOL

Focus on rare earth magnets. Almost all media journalism majors do not understand how magnets dominate the issue. Rare Earth elements get more media and thus more focus, but only the magnets matter.

Find talk about them, and only them. 2029.

About 31 ppm of the Earth's crust is yttrium, making it the 43rd most abundant element

With as much as 700 ppm, the seeds of woody plants have the highest known concentrations

Xenotime, a REE phosphate, is the main HREE ore containing as much as 60% yttrium as yttrium phosphate (YPO4). This applies to xenotime-(Y). The largest mine is the Bayan Obo deposit in China, making China the largest exporter for HREE since the closure of the Mountain Pass mine in the 1990s.

Ion absorption clays or Longnan clays are the weathering products of granite and contain only 1% of REEs. The final ore concentrate can contain as much as 8% yttrium. Ion absorption clays are mostly in southern China. Yttrium is also found in samarskite and fergusonite

One method for obtaining pure yttrium from the mixed oxide ores is to dissolve the oxide in sulfuric acid and fractionate it by ion exchange chromatography. With the addition of oxalic acid, the yttrium oxalate precipitates. The oxalate is converted into the oxide by heating under oxygen. By reacting the resulting yttrium oxide with hydrogen fluoride, yttrium fluoride is obtained. When quaternary ammonium salts are used as extractants, most yttrium will remain in the aqueous phase. When the counter-ion is nitrate, the light lanthanides are removed, and when the counter-ion is thiocyanate, the heavy lanthanides are removed. In this way, yttrium salts of 99.999% purity are obtained. In the usual situation, where yttrium is in a mixture that is two-thirds heavy-lanthanide, yttrium should be removed as soon as possible to facilitate the separation of the remaining elements.

The red component of color television cathode ray tubes is typically emitted from an yttria (Y2O3) or yttrium oxide sulfide (Y2O2S) host lattice doped with europium (III) cation (Eu3+) phosphors. The red color itself is emitted from the europium while the yttrium collects energy from the electron gun and passes it to the phosphor.

yttrium compounds such as yttrium aluminium garnet (YAG) are useful for phosphors and are an important component of white LEDs.

yttria is used to make yttrium iron garnets (Y3Fe5O12,"YIG"), which are very effective microwave filters

Yttrium is used to increase the strength of aluminum and magnesium alloys. The addition of yttrium to alloys generally improves workability, adds resistance to high-temperature recrystallization, and significantly enhances resistance to high-temperature oxidation

https://en.wikipedia.org/wiki/Yttrium

I appreciate your very informative Comment #26

https://freerepublic.com/focus/f-bloggers/4354201/posts?page=26#26

.

INTERESTING ARTICLE

What Are Rare Earth Elements, and Why Are They Important for Space Exploration?

Nov 13, 2025

https://newspaceeconomy.ca/2025/11/13/rare-earth-elements-the-unsung-heroes-of-space-exploration/

Rare earth elements (REEs) are a group of 17 chemically similar metallic elements. This group consists of the fifteen lanthanides (lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium, and lutetium), plus scandium and yttrium.

Despite their name, most aren’t actually that rare in Earth’s crust. Cerium, for example, is more abundant than copper. The “rare” part refers to the fact that they are seldom found in concentrated, economically exploitable ore deposits. They tend to be dispersed, mixed with one another, and often alongside radioactive elements, such as THORIUM and URANIUM, which makes their extraction and processing difficult, expensive, and sometimes environmentally controversial.

These elements possess unique magnetic, luminescent, and electrochemical properties that make them essential for a surprisingly large number of high-tech applications, including the technologies that are propelling us into the space age.

HMMM, Remembering...

URANIUM BRINGS TO MIND... the sale of the uranium mining company Uranium One to the Russian state-owned corporation Rosatom as a $145 million bribery scandal that involving Hillary Clinton and the Clinton Foundation.

2005: $145 million alleged bribes to Clinton Foundation

Frank Giustra donated $31.3 million to the Clinton Foundation, to be followed in 2007 with a pledge of at least $100 million. These amounts constituted the bulk of the $145 million in supposed bribes paid to the Clinton Foundation.

2007: Uranium One acquired UrAsia Energy

On April 20, 2007, Uranium One, a Canadian mining company with headquarters in Toronto, acquired UrAsia Energy, a Canadian firm with headquarters in Vancouver, from Frank Giustra, who then resigned from the UrAsia Energy Board of Directors.

Having severed ties with UrAsia Energy and Uranium One in 2007, Giustra had no evident beneficial interest in the subsequent sale of Uranium One to Rosatom in 2010, as he sold the 2,790,000 Uranium One shares he received in exchange for his shares of UrAsia in 2007. (Per the deal terms, UrAsia shareholders received 0.45 shares of Uranium One for each share of UrAsia they held.)

UrAsia has interests in rich uranium operations in Kazakhstan, and UrAsia Energy’s acquisition of its Kazakhstan uranium interests from Kazatomprom followed a trip to Almaty in 2005 by Giustra and former U.S. President Bill Clinton where they met with Nursultan Nazarbayev, the leader of Kazakhstan. Giustra denies reporting by The New York Times that he and Clinton traveled together to Almaty.

Substantial contributions to the Clinton Foundation by Giustra followed, with Clinton, Giustra, and Mexican telecommunications billionaire Carlos Slim in 2007, establishing the Clinton Foundation’s Clinton Giustra Sustainable Growth Initiative to combat poverty in the developing world.

In addition to his initial pledge of $100 million, Giustra pledged to contribute half of his future earnings from mining to the initiative. There is no indication that Giustra was contemplating any transaction with Russian interests at the time he began donating to the Clinton Foundation in 2005; rather, he sold UrAsia Energy to Uranium One, a South African-Canadian company based in Toronto, in 2007. That sale was completed two months before he made his pledges to the Clinton Foundation.

Since uranium is considered a strategic asset with national security implications and Uranium One owned uranium mining operations in the United States, the acquisition of Uranium One by Rosatom was reviewed by the Committee on Foreign Investment in the United States (CFIUS), a committee of nine government cabinet departments and agencies including the United States Department of State, which was then headed by Hillary Clinton. Clinton herself did not sit on CFIUS, but rather the State Department was represented by Jose Fernandez, the Assistant Secretary of State for Economic, Energy and Business Affairs, who stated that Clinton was not involved in the Uranium One matter.

Although CFIUS members can object to such a foreign transaction, none did, and no member can veto a decision; veto power rests solely with the president. CFIUS unanimously approved the Uranium One sale. The Utah Division of Radiation Control and Canada’s foreign investment review agency also approved the transaction.

2010: $500,000 payment to Bill Clinton

On June 29, 2010, Renaissance Capital, a Russian investment bank with ties to the Kremlin and which was promoting Uranium One stock, paid Bill Clinton $500,000 for a speech in Moscow shortly after the Rosatom acquisition of Uranium One was announced.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.