More pics at the link.

Posted on 05/02/2010 4:43:08 PM PDT by csvset

NEAR KERMIT, W.Va.

Floodlights glared deep in a century-old tunnel under an Appalachian hillside. An excavator poked at the arched ceiling like a pterodactyl.

Chunks of sandstone shattered and fell thunderously into an empty rail car.

Work has gone on like this for nearly a year. Crews begin at 2 a.m. and call it a day about noon.

In late March, they still were a few hundred feet from the south end of Norfolk Southern’s Big Sandy 1, a 2,627-foot railroad tunnel burrowed through a hill that sits along the Big Sandy River separating West Virginia from Kentucky.

Their task: to carve a higher clearance in the ceiling of the tunnel, making it big enough to handle rail cars loaded with cargo containers stacked two-high, doubling the railroad’s capacity and giving shippers more bang for their buck.

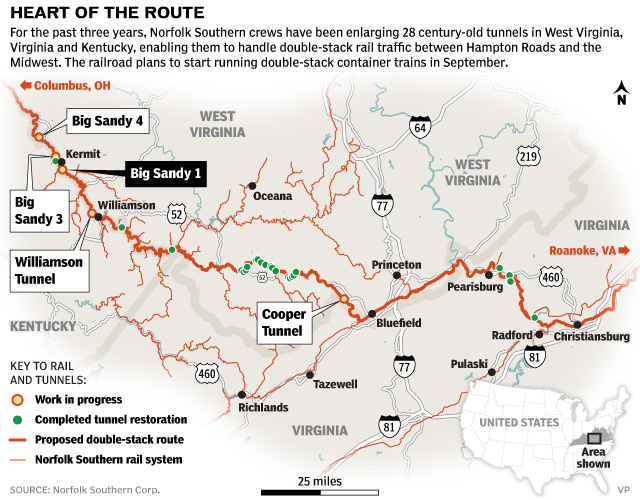

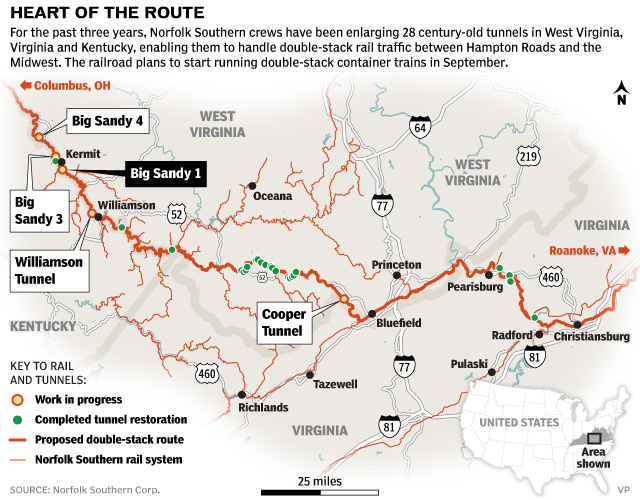

It is one of 28 tunnels that form the centerpiece of what Norfolk Southern calls “the Heartland Corridor,” a sort of Northwest Passage for double-stack rail traffic between Hampton Roads and the Midwest that will shave 230 miles and about a day of transit time from existing routes.

Combined with the port’s 50-foot channels and ready access to the open sea, it’s anticipated to have a magnetic effect on East Coast container traffic.

The taller tunnels will make Hampton Roads “much more competitive with the other ports,” said Bob Billingsley, Norfolk Southern’s director of structural projects, who has been overseeing the tunnel work. “That’s the only reason we’re doing it. That’s what it’s all about.”

For the past three years, working in the wee hours to avoid disrupting rail traffic, Billingsley’s crews have been raising the roofs on tunnels in West Virginia, Virginia and Kentucky, enabling them to handle the 20-foot, 3 -inch-high container trains that have had to go around the mountains, through Pennsylvania and Tennessee, because the tunnels were too small.

The railroad plans to start running the double-stack trains in September.

“It’s the biggest engineering undertaking we’ve had in the last 100 years – one of the biggest in modern railroad history, anyway,” Billingsley said.

Each of the tunnels – 23 of them in West Virginia, four in Virginia and one in Kentucky – has presented a unique puzzle, a slightly different configuration of rock and soil.

“I’ve learned something almost every day,” said Billingsley, who after spending most of his career working with steel, including a stint overseeing structures at Norfolk Southern’s Pier 6 coal-loading facility, suddenly found himself a student of mineralogy and geology.

The tunnels, built around 1905, have stood at 19.5 feet from track to ceiling. They need to be an average of 1.5 feet taller, including a 9-inch cushion, to accommodate the double-stack trains.

In five tunnels, the answer was simple: lower the track bed. In five others, the crew cut “notches” where the walls met the ceilings, allowing enough room for the corners of the containers. In one case, a bypass was built to skip the tunnel altogether; in another, the tunnel requires more extensive work.

In Big Sandy 1, as in 15 other tunnels, it meant taking out “the whole crown of the tunnel, from about 9 to 3 on a clock,” Billingsley said. Work in this tunnel began with the boring of hundreds of investigatory holes into the overhead liner, removing core samples and inserting a tiny camera that took photos of the rock and soil superstructure to assess its condition.

The excavator then went to work, pecking out the curved tunnel roof, chunks at a time.

A series of 13.5-foot supporting “rock bolts” were drilled into the exposed new “roof” before it was sprayed with quick-set concrete from a miniature concrete-plant-on-rails.

The work has been tough, tedious and dangerous.

On Oct. 22, a crewman working on Big Sandy 3, another tunnel a few miles away, was killed, buried under more than 100 tons of rock that fell on the excavator he operated. It has been the only fatality since the project began.

Progress in Big Sandy 1 means clearing anywhere from 15 to 30 feet – on a good day.

Every day they must clear the tracks before the coal and freight trains resume running, which explains the early hours.

The crew generally hits the sack when most people are having dinner, if not earlier.

“The hardest part of it has been fighting the night shift,” said Michael Parham, 29, a civil engineer from Tennessee who helped gather video and geo-technical data from the tunnel ceilings. “From 2 a.m. until the sun comes up, you’re just fighting to stay awake.”

While the tunnel work is the heart of the Heartland Corridor, there are two other components – one in Hampton Roads, another in Columbus, Ohio – all financed through a public-private partnership drawing on federal, state and railroad funds.

The local link involved relocating Commonwealth Railway’s line that connects Suffolk to APM Terminals in Portsmouth – and, eventually, Craney Island, where the port plans to build a fourth state cargo terminal. The line is being shifted from populated areas of Churchland and Western Branch to the medians of Interstate 664 and Va. 164.

The Ohio piece involved building a rail facility in Columbus – the Rickenbacker Intermodal Terminal – to handle cargo containers that can move interchangeably by rail, truck or ship.

The tunnel clearance cost about $190 million, while the rail relocation and Ohio terminal reached about $123 million. Federal and state funding has covered about $183 million of the $313 million, according to port documents and Norfolk Southern officials.

The idea of linking the three projects together evolved gradually, driven in part by the realization that, at the beginning, nobody was thinking big enough, said Robert Martinez, Norfolk Southern’s vice president for business development and a former Virginia transportation secretary.

“We weren’t asking for enough money,” Martinez said. “We weren’t being noticed.”

It wasn’t until a Washington lobbyist met with Norfolk Southern executives about five years ago to discuss the APM/Craney rail relocation project that the big picture began to emerge, Martinez said.

The lobbyist advised them that the reason the tunnel project wasn’t getting congressional funding support was because the railroad wasn’t seeking enough money. He suggested combining the projects and working together to get funding.

A single project soon emerged.

“We came up with the name 'Heartland Corridor’ to brand the entire route,” Martinez said.

As the Heartland Corridor project came together, a series of events in the global shipping industry dovetailed with it.

Labor strife and congestion had been frustrating shippers into West Coast ports, prompting them to look for ways to diversify their transit options, including using East Coast ports.

Plans were announced for an expansion of the Panama Canal, to be completed in 2014, which will allow larger vessels to work the “all-water” route from Asia to ports such as Hampton Roads.

“What the Heartland Corridor will do is it will alter the strategic position of this port relative to its competition,” Martinez said.

Industry experts agree the project is a positive development for the port but aren’t so sure it will change Hampton Roads’ competitive position with ports such as New York/New Jersey.

“Is it a game-changer in the competition between the ports? No,” said Thomas Finkbiner, who headed up Norfolk Southern’s intermodal operations during the 1990s and now is senior chairman of the Intermodal Transportation Institute’s board of directors at the University of Denver.

“I don’t devalue the fact that it is a very big thing for the port of Norfolk, for Norfolk Southern and for taking freight off the highway,” Finkbiner said. However, “there are bigger things in the supply chain” that dictate where cargo goes.

Representatives of two shipping lines said it’s the shippers themselves – major importers such as Target, Wal-Mart and Home Depot – that decide how and where to route their cargo through U.S. ports.

“It is not a decision by the shipping line as to where we want to route this cargo,” said Frankie Lau, a spokesman for Hong Kong-based Orient Overseas Container Line. “It’s basically the customer’s choice.”

Shipping lines present importers with a menu of options that can include going through West Coast ports and railing goods to Chicago – which for Asian cargo offers the fastest transit time – or going the all-water route through the Panama Canal to East Coast ports for distribution by rail and truck. The Heartland Corridor will put another option on the table, Lau said.

Key factors in the decision are typically focused on transit time, price and, increasingly, “carbon footprint,” he added.

It takes about 18 days to get goods from Hong Kong to Columbus, Ohio, via West Coast ports, said William Weng, director of intermodal shipping for Shanghai-based China Shipping.

Going through the Panama Canal to Norfolk and using the Heartland Corridor will take about a week longer, yet costs about $500 less per container, Weng said.

The decision comes down to time-sensitivity versus cost, he said. Goods such as computers, TVs, video games and some garments such as dresses are more time-sensitive, Weng said. Furniture, toys and household tools are not and would be candidates for the longer, cheaper route.

But Norfolk has benefited as shippers have diversified their routing options, said Jon DeCesare, president of World Class Logistics Consulting Inc., based in Long Beach, Calif.

“If you look at the East Coast, Norfolk’s in the strongest position,” DeCesare said.

The port has some drawbacks, too, he added, citing its dependence on a dominant rail carrier – Norfolk Southern – and the threat of congestion problems as the port grows.

Yet the Heartland Corridor’s improved link between two of the biggest transportation nodes in the nation – Hampton Roads and Columbus, Ohio – will give the port an edge as shippers continue to grow their mix of routing options, he said.

“Norfolk’s going to be on the top of the list,” DeCesare said.

Before Norfolk can get there, the tunnel work must be done.

And finishing the job means dealing with the unexpected.

In Big Sandy 4, one of the last of the tunnels to be completed by early August , workers discovered an underground spring seeping 5 gallons of water a minute.

“You never know what you’re going to find, so you got to deal with it as it comes,” Billingsley said.

The soil is so unstable above Big Sandy 4 that crews are constructing a new tunnel in the last 100 feet of the old tunnel, inserting a steel-and- concrete canopy.

Still, Billingsley said, the biggest challenge has been operating within a tight 2 a.m.-to-noon window that allows two Norfolk Southern trains hauling time-sensitive freight for the United Parcel Service to stay on schedule.

Even though the project is about speeding such freight through the mountains, progress is measured in feet.

“You get in a pattern or routine,” Billingsley said, “you can’t be in a hurry.”

Robert McCabe, (757) 446-2327, robert.mccabe@pilotonline.com

More pics at the link.

Port Newark losing one more advantage.

We need more obamarail, not this pro business investment.

The Big Bend Tunnel, where John Henry duelled with the steam drill, is also CSX line and still in use, but slightly north of this route.

Slight correction: the Big Bend Tunnel of today replaced the tunnel of the same name where John Henry is said to have “died with his hammer in his hand.”

You don't have to blast or dig away all those tons of rock either to lower the track grade or raise the roof.

All those alterations have already been made where needed. But since the extra expense was minimal to begin with, most bridges and underpasses were built higher than necessary. The big bridge on Marietta Boulevard over the entrance to the Norfolk Southern rail yard has not been altered for double-stack containers. The bridge is at least 40 years old and probably much older.

They did raise the Pryor-Alabama Street viaduct downtown when Underground Atlanta was refurbished (in vain) about 15 years ago, with a combination of new overpasses and lowering the main track. Part of it may have been done when the MARTA rail line was installed. But in that case we're talking about stuff that was at least 100 years old.

I wonder how they plan to deal withe higher center of gravity fo the trains? That is a challenge as formidable as anything else.

Are they going to eliminate curves?

Reduce the speeds to 5 MPH?

Pass a new ObamaLaw that outlaws physics?

Limit the upper containers to hauling only styrofoam?

What?

Double-stack container trains have been running for years. They just haven’t been running through those tunnels.

LOL! You got your Willie impression about down pat!

So the USG is subsidizing the construction to make it cheaper to get goods from Asia to the Heartland. Think about that. Maybe we could invest in improving the infrastructure for domestic manufacturing.

Anyone who believes this will work can go buy any of the millions of sq ft of distro/warehousing space in bankruptcy in Columbus Ohio today.

Corrupt gov subsidies to sell trinkets to the native Americans?

Think about how far we’ve progessed, once all we had were smallox blankets and Springfield rifles to destroy the indigenous. Today they cross oceans and move mountains to subjugate the American Heartland.

How much of this money could have gone towards SBA homespun manufacturing companies?

How many years until the US Dollar crashes and the manufacturing wages in the Heartland are globaly competitive?

Why ask these questions when you can rent a lobbyist and get a few hundred mill to boost shareholder dividends?

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.