Skip to comments.

Military Looks to Develop Hybrid Trucks

AP on Yahoo ^

| 5/2/06

| Emily Fredrix - ap

Posted on 05/02/2006 12:49:00 PM PDT by NormsRevenge

OSHKOSH, Wis. - At the top of a 10-foot-high mound of dirt, Gary Schmiedel takes in the silence. The military truck he's driving barely hums just before it careens down a steep incline into a muddy pool.

Normally the vehicle — a Heavy Expanded Mobility Technical Truck or HEMTT — would be so loud the occupants wouldn't be able to talk to each other, said Schmiedel, vice president of product engineering for Oshkosh Truck Corp. But this version is about as loud as a standard sedan, with a smooth ride, splashy computer screens and a comfortable interior.

This isn't your dad's military truck, a bumpy, loud gas guzzler. This is a hybrid made at the request of the Defense Department.

Oshkosh Truck, the military's exclusive provider of the Army's heavy cargo-hauling HEMTT vehicles, is finishing up prototypes of its electric hybrid. It not only increases gas mileage by about 20 percent from the standard 3 to 4 miles per gallon, it generates enough electricity to power a city block or hospital. The company, based in this city about 100 miles north of Milwaukee, just signed a contract to produce a prototype of a similar vehicle for the Marines.

It's not clear how the hybrid technology will affect prices for the military vehicles, whose diesel version costs from $200,000 to $400,000, said Schmiedel, vice president of advanced product engineering for Oshkosh Truck. Even modest reductions in gas mileage help, he said, pointing out that 70 percent of what military vehicles carry is fuel.

The hybrid technology can be far-reaching, said Schmiedel. Commercial vehicles such as garbage trucks and emergency vehicles all could benefit from using less fuel, he said. The Department of Energy has said it hopes to double the fuel economy of garbage trucks by 2010.

The ability to generate power could be another selling point, Schmiedel said. The technology has a storage system capturing energy that would otherwise be wasted in the braking process. The generator can produce up to 300 kilowatts of power — enough to run 50 homes for an indefinite amount of time, he said. In response to Hurricane Katrina, Oshkosh took a hybrid truck to New Orleans and used it to pump out a hospital basement.

"First and foremost it's a truck. If it has the flexibility to act as a generator in a pinch, that's a heck of a disaster recovery attribute," Schmiedel said.

The military is working with several companies to get power systems into its hybrid vehicles, said Paul Mehney, communications officer with the U.S. Army Tank Automotive Research, Development and Engineering Center, in Warren, Mich. Hybrid generators would eliminate the need to haul in a separate diesel generator, he said.

"It comes in real handy in the field. You can power an operation center out of that. You can power water purification systems off that," Mehney said.

The push to develop heavy hybrids will be huge in the coming years as companies tweak products for different markets, said Robert McCarthy, an analyst with Robert W. Baird & Co.

While manufacturers such as Honda and Nissan have said they're considering slowing down production of hybrid vehicles due to sluggish sales, development of the technology for military and commercial use doesn't seem to be waning, Schmiedel said. FedEx recently announced it would add 75 diesel electric hybrids to its fleet of 18 in use in Sacramento, New York, Tampa and Washington, D.C.; and refuse and recycling hauler Waste Management Inc. has worked with three companies, including Oshkosh Truck, to develop hybrid technology and alternative fuels for its fleet of 22,000 vehicles.

Schmiedel and others at Oshkosh have been working since 1999 on the technology, called ProPulse. The company has made two trucks. It plans to make a few more and turn them over early next year for government testing, a process that could take a year, he said.

Though hybrid technology has been around for several years in passenger vehicles, adapting it for larger vehicles isn't as easy, Schmiedel said. Military vehicles must often carry thousands of pounds of cargo — 13 tons for the HEMTT — and endure hills, little pavement and angles that few standard vehicles can handle. That all means engines and axles must be configured just so.

In the case of the newest version — called the HEMTT A3 — a diesel engine powers a generator that sends power to electric drive axles. Energy is stored when trucks coast or decelerate. The motor turns into a generator and provides power back into the vehicle, which can be used for the next acceleration or later to power outside sources.

In tweaking the ProPulse technology, Schmiedel said engineers created dozens of other perks, such as shrinking vehicle weight and placing engines in a way that makes maintenance easier. A specialized technician used to spend up to 24 hours swapping an engine but now any mechanic can do it in 20 minutes.

"What we think will drive hybridization is when there is some benefit over and above saving fuel," Schmiedel said.

Other attributes include a center of gravity that is nearly a foot lower than the older vehicles, meaning tipping is less likely. Because the engine is shifted, the interior cab isn't broken up by the girth — and noise — of the engine, which means there's space for a third passenger.

Oshkosh Truck, which saw nearly $3 billion in sales last year, has made nearly 20,000 HEMTTS, with an estimated 2,500 in use in Iraq. One-third of the company's sales come from the military. The company also makes tow trucks, garbage trucks, concrete mixers and fire trucks.

Though other companies are working on similar technologies, it makes sense for the government to contract with Oshkosh because it already supplies the Army's heavy military vehicles, said McCarthy, the Robert W. Baird analyst. He warned that progress will be slow even though the industry has come a long way in advancing its hybrid technology.

"The fuel efficiency savings for those applications can be huge. If you have the additional advantage of being able to use some of that power to operate other systems like you would in a garbage truck, even better," he said.

___

On the Net:

Oshkosh Truck: http://www.oshkoshtruckcorporation.com

TOPICS: Business/Economy; Foreign Affairs; News/Current Events

KEYWORDS: develop; hemtt; hybrid; looks; military; oshkosh; propulse; trucks

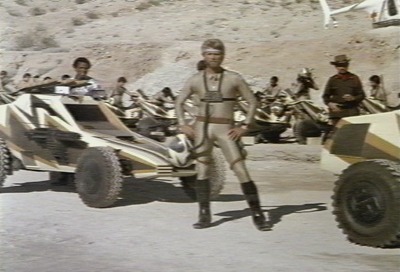

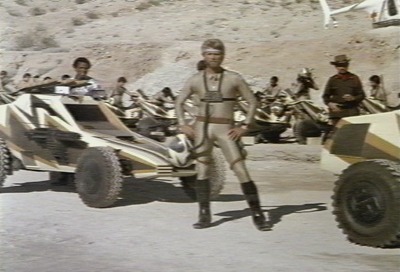

Oshkosh Truck executive Gary Schmiedel drives their diesel hybrid truck up a hill at the company's test track Tuesday, April 11, 2006, in Oshkosh, Wis. Oshkosh Truck, the military's exclusive provider of the Army's heavy cargo-hauling HEMTT vehicles, is finishing up prototypes of its electric hybrid. It not only increases gas mileage by about 20 percent from the standard 3 to 4 miles per gallon, it generates enough electricity to power a city block or hospital. The company, based in this city about 100 miles north of Milwaukee, just signed a contract to produce a prototype of a similar vehicle for the Marines. (AP Photo/Morry Gash)

To: NormsRevenge

A fully loaded deuce and a half would take a pretty darn powerful battery I would think.

To: NormsRevenge

It kind of looks like a beetle to me..

Oshkosh is a leader in the development of next-generation hybrid propulsion systems in heavy trucks. ProPulse® is an unmatched hybrid electric drive system that dramatically improves fuel economy, reduces emissions, improves life cycle costs, and serves as an on-board AC generator with enough output to power an entire airfield or hospital.

“This leading-edge technology is the first significant step toward the development of an entirely new generation of highly mobile and incredibly efficient trucks. Our focus is on enhancing performance characteristics while making trucks environmentally friendly,” said Robert G. Bohn, Oshkosh’s chairman, president and CEO.

The ProPulse system uses a unique, modular series-hybrid arrangement to simplify the transmission of power to the wheels. The diesel engine powers an electric generator, which provides direct power to the wheels, eliminating the torque converter, automatic transmission, transfer case and drive shafts. The system has no batteries, using ultracapacitors for energy storage instead. A regenerative braking function stores engine energy and then uses it to assist in the next braking operation, reducing wear and tear on the brake system.

ProPulse has applications for Oshkosh’s entire line of products, including defense, refuse hauling, fire and emergency, and other commercial markets. Oshkosh has applied for patents on various aspects of the ProPulse design.

OshKosh Defense Products

Heavy Expanded Mobility Tactical Trucks (“HEMTT”); HEMTT-Load Handling Systems (“LHS”); Palletized Load System (“PLS”) trucks and trailers; Logistic Vehicle Systems (“LVS”); Heavy Equipment Transporters (“HET”); Medium Tactical Vehicle Replacements (“MTVR”); Wheeled Tankers, remanufacturing; armoring; worldwide integrated logistics support.

3

posted on

05/02/2006 12:57:03 PM PDT

by

NormsRevenge

(Semper Fi)

To: Gay State Conservative

The system has no batteries, using ultracapacitors for energy storage instead.

--

Those must be some big caps.

4

posted on

05/02/2006 12:57:56 PM PDT

by

NormsRevenge

(Semper Fi)

To: Gay State Conservative

Now you're getting to the locomotive model of building a truck. A Diesel engine driving a generator, and electric traction motors at each wheel. Add in a battery system to buffer sudden peak load demands and to capture energry from regenerative braking, and you have a decent truck.

The only fuel savings, however, would be in heavy stop and go traffic. You wouldn't see any savings on the highway or cross country.

5

posted on

05/02/2006 12:58:04 PM PDT

by

Yo-Yo

(USAF, TAC, 12th AF, 366 TFW, 366 MG, 366 CRS, Mtn Home AFB, 1978-81)

To: NormsRevenge

To: Yo-Yo

The only fuel savings, however, would be in heavy stop and go traffic. You wouldn't see any savings on the highway or cross country.You would if the electric drive train is more efficient than the mechanical transmission and drive shafts it replaced. I don't know if that is the case

To: Ursus arctos horribilis

Oh, You are so banned, Mr.! I (I stole that from an anonimus gramma here)

It's a good thing my cat wasn't close by.. I'd be cleaning up a mess.. I usually have my volume turned down,, Yiiiii...

8

posted on

05/02/2006 1:07:43 PM PDT

by

NormsRevenge

(Semper Fi)

To: Orbiting_Rosie's_Head

Well, if you want to get technical, the diesel runs at a more constant rpm at it's optimum efficiency range, so you might see some savings there as well. But we're talking a couple of percentage points, that would be in the noise level compared to things like proper tire pressure, up-armored cabs, etc.

In really huge vehicles such as locomotives or giant earth moving dump trucks (the 5 story high kind that work in open pit mines) an electrical "drive train" is more efficient than a purely mechanical one. However, on smaller applications the reverse is true, which is why Hybrid automobiles retain the mechanical engine and transmission, and add an electric motor to it, rather than having the engine drive a generator and have the electric motor drive the wheels.

9

posted on

05/02/2006 1:13:25 PM PDT

by

Yo-Yo

(USAF, TAC, 12th AF, 366 TFW, 366 MG, 366 CRS, Mtn Home AFB, 1978-81)

To: Yo-Yo

I agree about the fuel savings during driving, however;

Most military vehicles spend the majority of their lives just sitting there and running. That's why the latest M1A2 Abrams tanks now have Auxillary Power Units (APU) to power the turret drives, thermal sites and other equipment. Otherwise, that Lycoming turbine would still be running, devouring fuel. Even HMMWVs must remain running to support their radios.

My FDC track would sit in position, generator and/or engine running for two weeks at a time. A hybrid would be able to power the entire vehicle and all commo gear without the need for the 4.2K genset. A hybrid system of higher voltage than the current military 24V set would provide much more efficient power for all of the various crap they keep adding to vehicles.

I really think that hybrid technology will come to fruition under The US Army, which has led military vehicle development for quite some time. They have the buying power to pick up 50,000 hybrid trucks and jump start the next generation of hybrid vehicles.

10

posted on

05/02/2006 1:16:37 PM PDT

by

SJSAMPLE

To: Yo-Yo

11

posted on

05/02/2006 1:21:23 PM PDT

by

thackney

(life is fragile, handle with prayer)

To: SJSAMPLE

That would be a good application to have all the comm gear, and the cab A/C (full up-armored cabs) running off the hybrid batteries, and the main diesel automatically fires up every so often to recharge the battery pack.

I don't think they were looking at that much storage capacity in the 'supercaps' however. Just enough capacity to provide a sudden surge required when you floor it, and to recapture braking energy for the next initial shove forward again.

12

posted on

05/02/2006 1:24:45 PM PDT

by

Yo-Yo

(USAF, TAC, 12th AF, 366 TFW, 366 MG, 366 CRS, Mtn Home AFB, 1978-81)

To: thackney

13

posted on

05/02/2006 1:25:31 PM PDT

by

Yo-Yo

(USAF, TAC, 12th AF, 366 TFW, 366 MG, 366 CRS, Mtn Home AFB, 1978-81)

To: Gay State Conservative

A fully loaded deuce and a half would take a pretty darn powerful battery I would think.

-----

The idea is stupid. The cost of the vehicles would more than double, given the kind of horsepower requirements and battery systems that would be needed. The vehicles' size and weight would increase dramatically making it more difficult to transport them and limit where they could go...

14

posted on

05/02/2006 1:35:13 PM PDT

by

EagleUSA

To: NormsRevenge

> Normally the vehicle — a Heavy Expanded Mobility Technical Truck or HEMTT — would be so loud the occupants wouldn't be able to talk to each other, said Schmiedel, vice president of product engineering for Oshkosh Truck Corp. But this version is about as loud as a standard sedan, with a smooth ride, splashy computer screens and a comfortable interior.

I've heard this before...

15

posted on

05/02/2006 1:57:02 PM PDT

by

orionblamblam

(I'm interested in science and preventing its corruption, so here I am.)

Disclaimer:

Opinions posted on Free Republic are those of the individual

posters and do not necessarily represent the opinion of Free Republic or its

management. All materials posted herein are protected by copyright law and the

exemption for fair use of copyrighted works.

FreeRepublic.com is powered by software copyright 2000-2008 John Robinson