Political power grows out of the nozzle of a 3-D Printer.

Posted on 01/04/2019 1:31:05 AM PST by vannrox

On January 28, 1986, the space shuttle Challenger exploded. All seven astronauts were killed. Eyewitness Frank Mottek described the scene:

Just then we both stood up and looked up at the shuttle making its way farther and farther into the sky. Suddenly, I was struck by a pattern I had never seen before. From our vantage point, it appeared that an extra flame was trailing from the shuttle. Then, in that split second, a silent fireball appeared in the sky. Then there was silence, the silence of alarm. . .

Investigations later revealed that two rubber O-rings, which were designed to separate the sections of the rocket booster, failed. Rather than remaining supple, they cracked because of cold temperatures. Pressurized fuel escaped through the crack, ignited, and exploded.

Challenger is America’s Titanic, our Hindenburg. It is a disaster forever burned into our national consciousness. And yet we seem to have forgotten its most powerful lesson: the whole is only as strong as its weakest part.

Perhaps this sounds trite. But sometimes the simplest observations are the most consequential. In this case, trillions of dollars—if not America’s economic future—depends on understanding how O-rings fail.

O-Ring Economics

In 1993, Michael Kremer, a Harvard-educated developmental economist, wrote a paper called “The O-Ring Theory of Economic Development.” The Challenger disaster for Kremer was not just a tragedy, it was also a parable that helped explain why workers in some countries and industries earn exponentially more than workers in other countries and industries, despite doing basically the same job. It all comes down to fragility and exponents.

Here’s how it works:

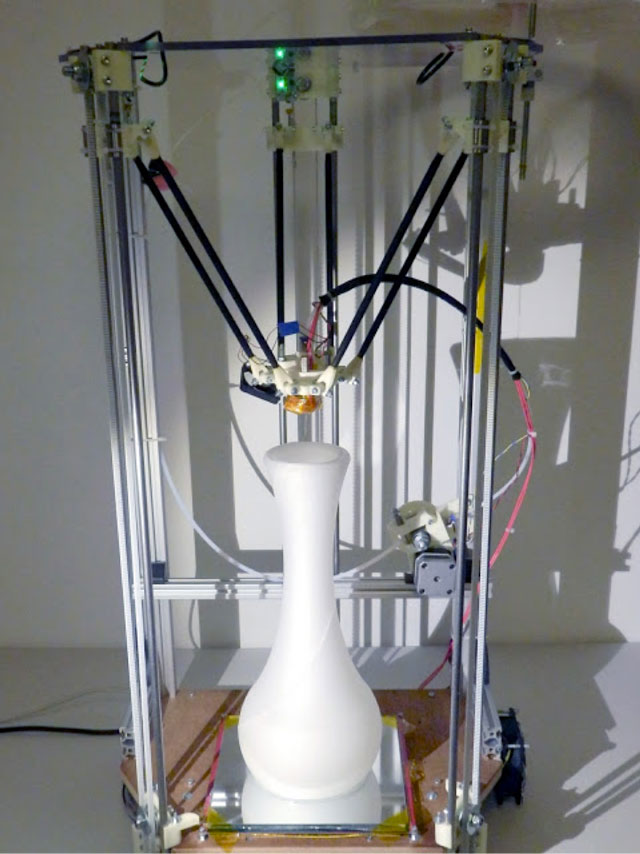

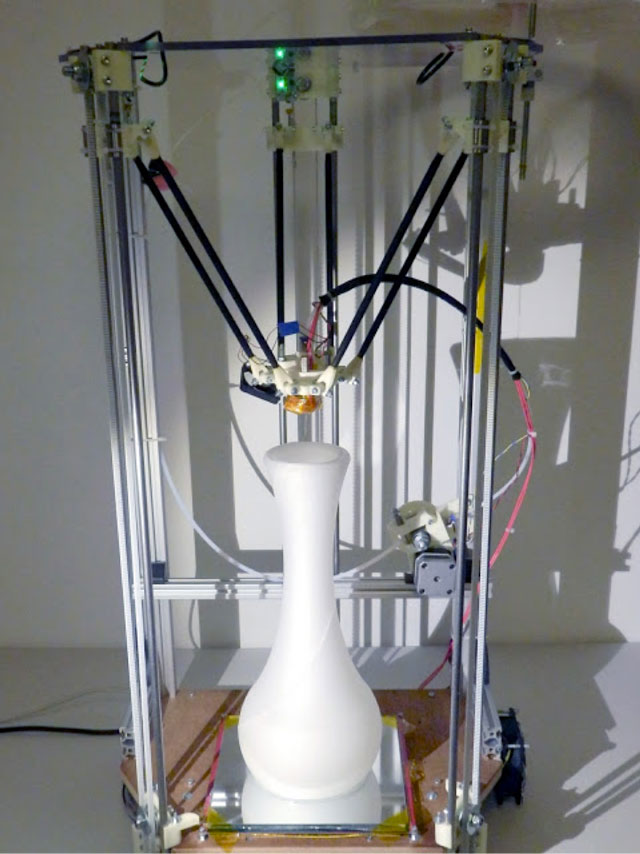

You own a factory that makes glass vases. It takes two workers to make one vase: one worker blows the molten glass, the other packs the vase for delivery. If either worker drops the vase it will shatter and become worthless. What a waste!

You have four workers. Two of them never drop the vase. Two of them drop it half the time. If you want to make as many vases as possible, how should you divide your workers?

Instinct tells us to pair the good and bad workers—that way both teams will have someone who knows what they’re doing, and both will be somewhat successful. This is a bad idea. If you did this then both teams would break 50 percent of the vases.

The better option is to pair the good workers together and let the bad workers make a mess. Why? Together the good workers would succeed 100 percent of the time. Meanwhile, the bad workers would succeed 25 percent of the time. On average, the teams would succeed in making vases 62.5 percent of the time. The second option is the clear winner.

This example highlights two important lessons. First, vase production is fragile—one small mistake at any point in the production-chain can destroy the whole vase. The chain is only as strong as its weakest link. Second, increasing the production chain’s complexity (for example, by adding third step) will increase the fragility in a non-linear way. How?

Imagine that you also need to paint the vases, adding a third step. Although your two good workers succeed 100 percent of the time, they are forced to work with butterfingers, who drops the vase half the time. In this case, the entire factory’s productivity decreases from 62.5 to 50 percent. Now pretend that you also need to varnish the vases, adding a fourth step. Your final employee is also a dropper, and decreases the factory’s output to 25 percent.

Now pretend that it takes 100 steps to make a vase: you have 97 employees who succeed 100 percent of the time, and just three bad employees (who succeed 50 percent of the time). In this case, the factory’s production efficacy would decrease to just 12.5 percent—despite the fact that you hired an army of competent workers!

When it comes to O-ring economics, one bad apple really does spoil the bunch.

Product Complexity and Managerial Bloat The above logic has profound implications for America’s trade policy—implications that America’s economic stewards completely ignore.

To begin with, moving production abroad adds complexity (extra steps to the production chain), which increases the likelihood that something will go wrong. And remember, this complexity harms production in a non-linear way—even a small failure in an otherwise flawless production chain can destroy the entire product. Technologically sophisticated output is especially vulnerable.

For example, Boeing’s 787 Dreamliner suffered numerous delays, cost-overruns, and safety problems because the international supply chain was too complex. Consider that Boeing employed some 50 different contractors, each of whom was responsible for designing and manufacturing a piece of the airplane. Complicating things further was the fact that these contractors often sub-contracted their production. And no doubt these sub-contractors further sub-contracted their work.

This is the economic equivalent of the Hindu’s infinite regression: it’s subcontractors all the way down.

God only knows how many different companies, located in how many different countries, worked on the 787. Rather than building an airplane, Boeing was building a puzzle with pieces of obscure provenance. Basically, Boeing had no idea if it was employing “vase-droppers” until it was too late.

The fact that things have not gone wrong for America on an apocalyptic level is largely due to the fact that American companies have hired legions of business consultants, logistics engineers, and risk-managers to “streamline” international supply chains. In fact, the growth of America’s managerial class is largely a response to offshoring and to the burden of increasing complexity.

Economists never account for the cost of this additional management when they discuss offshoring. Instead, the existence of a bloated managerial class is simply taken for granted.

This raises the question: are Chinese goods cheap, or do they appear cheap because we ignore the opportunity costs associated with employing millions of Americans in nonproductive jobs? How many billions of man-hours do we waste coordinating the labor of Chinese peasants? How many more are wasted coordinating the coordinators?

America is sacrificing its productive human capital on the altar of complexity: we trade the wisdom of makers for the trickery of takers.

Oscar Wilde’s Wisdom Complexity is not just an economic problem, it’s an existential threat.

In his book The Collapse of Complex Societies, Joseph Tainter argues that civilizations collapse because they can no longer maintain their level of organizational, economic, and technological complexity. Increasing complexity is driven by an autocatalytic process—as societies grow they require more organization, which enables them to grow bigger still etc. Oscar Wilde sums up this idea neatly: “The bureaucracy is expanding to meet the needs of the expanding bureaucracy.”

Eventually, society becomes too complicated to survive with the available technology. Collapse becomes inevitable. Symptoms of an impending collapse often include the expansion of bureaucracies—bureaucrats being loosely defined as “organizers” rather than “producers”—increased taxes to pay for said bureaucracies, the proliferation of laws, increasing debt, currency debasement, widening economic inequality, and the consolidation of capital (land) ownership.

You don’t have to be Tiresias to see that America—if not Western Civilization itself—is nearing a complexity-driven collapse.

Our bureaucracy is bloated: over 22 million Americans work for the government (twice the number that work in manufacturing), and more than 60 percent of our people rely on the government for sustenance. The majority of Americans are de facto wards of the state. Ours is a nation of takers, not makers.

If America is going to survive and prosper, we must simplify the economy. Otherwise we will crash and burn for want of an O-ring.

There are too many “O ring” voters (democrats).

Well the manufacturing realities discussed in this article are 100% on the money. Manufacturing a product at profitability, keeping the reject ratio above 96%, is a herculean effort in risk management. In China, there are 1,000 little things to watch, which you could probably take for granted on a product made in the West.

The article doesn’t specifically point out that it was the O-ring failure that gave modern industries these concepts, the concept of risk management to a sigma level being introduced by NASA (or the Japanese before that, one could argue). At NASA, a product can never-ever explode. Producing umbrellas on the other hand, is a lot less critical, and the risk management a lot more relaxed. Hence, we get sh*tty products that make it into the containers and into our stores.

I have discovered, after a lot of pain, that Taiwan is the better choice. They are already steeped in the methods of the West. Their prices are just about on par with mainland China. They are really eager and willing, and just flat easier to do business with. My hope is that other manufacturers wise up to this observation.

And yet globalism is embraced by the “elites”.

The term o-ring always makes me think of the men’s room scene in Austin Powers.

Ummmm - if the two klutzes each drop the vase half the time, then to 25% success rate is based on bad math - but from another post, you are so insulated in your little Chinese world that it must make perfect sense to you to ignore things you disagree with.

For instance, automobiles now last far longer than in the middle 20th Century, when passenger autos, though simpler in construction, were usually worn out and economically unrepairable by 100,000 miles; many long before.

It took the shift of the American customer base buying superlative Japanese products manufactured under Deming's TQM principles to forcefully wake up car manufacturers here.

And that wakeup in terms of attitudes of assembly-line workers has been only partial. Plenty of them have necessarily been supplanted by robotic technology.

I live in a county whose two large auto plants, quite active when moved here 35 years ago, have long been shuttered.

First off, you’re egregiously-wrong (”At NASA, a product can never-ever explode.”); history makes the point and with their vested interest in promoting climate change, they have lost my support forever absent leadership which is still lacking from even Trump.

Second, you’ve missed the point of the article altogether with your last (”I have discovered... that Taiwan is the better choice. ... My hope is that other manufacturers wise up to this observation.”).

". . . quite active when I moved here 35 years ago . . ."

Actually, these plants had been here from perhaps the 1920s; GM and Chrysler.

Political power grows out of the nozzle of a 3-D Printer.

AI will save us. :)

The MBA class decided in the Seventies that American workers were the expensive, drug-abusing vase-droppers. A “disciplined” workforce overseas looked much more attractive in that era of crumbling American quality. And the complexity part is a natural tendency that needs to be guarded against in every business - whether it has off-shored operations or not.

Cheap labor only gets you so far for almost all (non textile) manufactured goods. Frankly, labor is but small cost component in the over cost to make a durable good. If labor was "free" i.e. slavery this would only save 3-5% on the cost of manufactured goods. To to increase the "bang for the buck" the foreign made goods are made with cheaper materials and lower quality control in order to get the price down because cheaper labor by itself can't do it alone. This done to justify destroying the USA's industrial base.

Sad. A tragedy. Think of the human suffering losing your livelihood and entire community in economic extremis.

I call them Free Traitors™.

Why keep vase droppers?

I heard that for some positions where there is a single job opening, Amazon will hire three people to do it for a trial period, then actually keep the best one. I’m sure most companies cannot afford to hire this way, and it an interesting way to avoid having to sequentially go through multiple candidates until you get to the one you want. Try them in parallel.

Bureaucracies typically act like living organisms in that they are always growing and consuming. Each individual within it is always trying to justify their cost and as a result the entire organization is doing this organically, even if it’s completely outside of it’s philosophies and procedures. It’s hard to find an example more obvious than when an organization is started (sometimes grass roots and without planning) for some temporary charitable or social cause. They are never temporary, and by the time they have been giving a lot of time to ‘evolve’, they have grown to become a massive monstrosity of complexity, each part of which is constantly, if even only subconsciously, attempting to secure and justify it’s own importance within the organization, which also includes attempting to justify the growth of the organization as a whole. The forces from within are always toward permanence, stasis, and protection (survival). Even a subcontractor to a subcontractor in the supply chain of a large organization is going to attempt to establish it’s own stasis including whatever growth and bloat that will eventually result from it. The tenancy is rarely ever toward more efficiency, except when it purely involves profit margins, but at an organic organization, margins are never the sole goal. “Growing the pie” may actually mean smaller margins, but those margins are from a greater overall revenue. Someone is usually examining decisions that reduce efficiency and increase growth in relation to the benefit, but not necessarily from outside of the organization. This can only be achieved by COMPETITION at every level.

Vase dropping should not be assumed.

Economists never account for the cost of this additional management when they discuss offshoring. Instead, the existence of a bloated managerial class is simply taken for granted.

—

Mush like a government agency which eventually supports nothing and produces nothing except a perpetuation of the government agency.

Answer:

Operations Research

The science of routing and distribution.

The problem is that except for a few highly skilled tasks most critical jobs can be done my someone who is smart, diligent and cooperative and willing to learn. Unfortunately interview and selection processes tend to weed those folks out right at the beginning of the candidate evaluation process because the one group of people who are not smart, diligent, coorperative and willing to learn are the idiots who end up staffing HR departments. In fact if you had a smart, diligent, coorperative and willing to learn CEO of the outfit, he would make HR redundant except for payroll and make the line organizations do their own hiring.

Disclaimer: Opinions posted on Free Republic are those of the individual posters and do not necessarily represent the opinion of Free Republic or its management. All materials posted herein are protected by copyright law and the exemption for fair use of copyrighted works.